Abstract

Biotechnology and food science have pioneered the notion of cultured meat. Conventional meat production face issues related to butchering, dietary inadequacy, foodborne disease, and the emanation of methane, which cultured meat evades while promising the texture and feel of real meat. Mass production techniques for plant-based meat analogs have been developed, whose products have hit the market. In vitro production on scaffolding and self-organizing techniques have manufactured small-scale meat products offering tunable nutrition, although more specialized contrivances are needed to build a cultured meat framework on a large scale. Prospective techniques like 3D/4D bio-printing, biophotonics, and cloning are current research subjects. Cultured meat needs to overcome societal and regulatory hurdles prior to commercialization, and, in any event, is a long-term necessity for humankind, although the high production cost and affirmation among people is the principal impediment.

Similar content being viewed by others

Introduction

The world's population of around 7.9 billion has nearly doubled over the past 50 years, with the number rapidly increasing every day.1,2 People depend upon resources: natural, man-made, or capital, for their livelihood and wellbeing. As the population rises, natural resources deplete more quickly, and, although renewable schemes exist, food scarcity remains one of the most challenging subjects.

Unlike vegetation, which can be reproduced and used to develop man-made hybrids, meat production relies on butchery, which concerns us all, as animals play an essential role in the ecosystem. The development of artificial meat may be the best substitute and a renewable form of meat production feasible in the future. People would be delighted to continue consuming meat without the undercurrent of fear or guilt.

Goldfish and lamb were the first successfully cultured meats,3 and various meat substitutes have since been cultured using suitable technologies.4,5,6 The world witnessed the first-ever laboratory-grown beef burger in 2013; although palatable, its production cost over US$330,000.7

Consuming red meat is associated with colorectal cancer, cardiac arrest, cardiovascular illness, and diabetes,8,9 due to specific components. These can be excluded or induced at lower concentrations, while those serving health benefits can be included10 in artificial meat products. Such products would also be unexposed to pesticides and bacteria, due to the controlled conditions in which they are manufactured.11,12

This review describes the current state of artificial meat, its tested methodologies, critics, and challenges, and the future of this revolutionary technology.

Present Scenario/Global Outlook

Global meat consumption could double by 2050 due to the growing population.13 However, there is a maximum to conventional meat production beyond which there would be high demand without any sources.14 Such a situation will increase prices and worsen the global distribution of food.

Artificial meat has assets and barriers that affect its outlook: products need to be large scale, reach out to a large audience, and produce a turnover and, subsequently, profit. Also, consumers are most likely to purchase novel products resembling existing ones without much change in their utilization experience15; only then will it compete with the established!

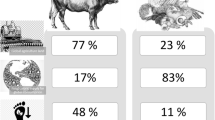

Plant-based meat alternatives are accessible in the market and have surpassed the only barrier, i.e., consumer acceptability, as people are credulous toward plant-based products.16 However, they account only for a small portion of the total market17 because of negative stigmas attributed to their taste and texture.18 Although these products are serious alternatives, they are not currently deemed so by non-vegans.16,17

The development of cultured meat is formative, and will take at least 10 years before being commercially available.19 Its development necessitates substantial commitment and investment from the government and industry, as new manufacturing facilities with several untested technologies would be required. Although it presents a significant risk for investors, consumers are showing interest in the product becoming available.20

The cloning process has been marketed and is available to companies.21 However, the procedure is costly and will probably see lower success than other artificial meat forms.22 Table I describes conventional and artificial meat production.23,24

Classification of Artificial Meat

Artificial meat is a broad term that encompasses three main types of meat replacements: meat alternatives derived from plant extracts and fungi; cultured (or laboratory-grown or synthetic meat) produced in vitro through tissue engineering or derived from genetically modified organisms and cloned animals through genetic engineering. Figure 1 depicts such a classification.

Fermentation-based meat substitutes (vegan meat) use non-animal proteins obtained from plants and fungi.25 For example, soya meals offer high nutritional content, texture, and flavor similar to regular meat. Quorn (manufactured from fungal protein) offers burgers, steak, and sliced meat alternatives free of cholesterol and low saturated fat.26

Tissue engineering enables in vitro production by seeding a scaffold with a few myocytes (i.e., muscle cells) and multiplying them through cell culture: the act of promoting cell development in an artificial medium through chemical and physical stimuli27 (used to regenerate plants28,29,30,31,32). Either cell source can create products:

-

(i)

Primary cells isolated from the original tissue or cell lines multiply in two ways: (1) by induction: teaching cells to multiply endlessly (genetic engineering or chemical manipulation),33 and (2) by spontaneous mutations in which the cell demonstrates immortality34

-

(ii)

Primary cells isolated from native tissue.

While muscle stem cells have garnered the most attention, others, such as mesenchymal stem cells (i.e., connective tissue cells of any organ), can grow in serum-free conditions35,36,37 due to their higher proliferation capacity.38 Although embryonic stem cells (i.e., early-stage embryo cells) multiply continuously, they are more challenging to guide toward a muscle cell lineage. Additionally, human primary cell sources are available;39 however, culturing human tissue for meat production would have profound ethical, medical, and regulatory ramifications.

Genetic engineering and biotechnology permit genome editing: sophisticated inter- and intra-species allele (i.e., gene) replacement technologies, to develop genetically modified organisms (GMOs).40 GMOs can be utilized as food, and are extensively employed in medicine, research, and the conservation of existing characteristics. Several GMO instances in food include transgenic pigs, the manufacturing of cheese, transgenic cows for milk production, and enviropigs for omega-3 fatty acid synthesis.41,42 Figure 2 gives an overview of artificial meat discussed in this paper.

Meat substitutes Derived from Plant-Based Sources

Quorn

Quorn is made from mycoprotein, whose primary component is Fusarium venenatum, a fungus found in soil. The fungus is fermented with sugar and centrifuged to give a batter utilized in various quorn items. Quorn can assist in lowering blood cholesterol levels and reducing energy expenditure.43,44

Quorn foods include vegan alternatives of patties, nuggets, cutlets, steaks, burgers, and prepared meals like lasagna. Compared to other vegetarian protein sources, they have no cholesterol, a low saturated fat content, a healthy fatty acid profile, and fiber content. Additionally, the amino acid content of mycoprotein is similar to those of other vegetarian and animal proteins. Figure 3 describes the detailed manufacturing process of quorn.45

Soya Meat

Soya meat (also known as textured vegetable protein) is a soya protein with fibrous consistency similar to regular meat. It contains more than 50% protein and makes high-protein grains, nuggets, and others.

Soya protein products have become popular due to their low price, good nutritional value, and diversity. There are two significant compounds: soya protein concentrate and soya protein isolate. With a minimum protein level of 65% on a dry weight basis, soya protein concentrate is an edible protein product, while soya protein isolate has a minimum protein content of 90%.46

Soya meat is made by combining soya protein with water at 30°C in an extruder for approximately 3 h to eliminate anti-nutrients. The material is pulped, heated, and denatured to eliminate husk and to obtain a puffy solid that is later dried. In order to create a well-texturized structure, the temperatures in the process section are typically kept relatively high, around 70°C for 5–8 h.47

Tempeh

Tempeh is the most recognized fermented food, and is high in nutrients and bioactive compounds.48 Tempeh is produced by soaking and cooking soyabeans, to which fungus is later added. After 24 h, the tempeh will have a nutty taste and a chewy mushroom texture, which makes patties and other meat substitutes. Tempeh’s protein content is significantly enhanced during fermentation, making it more digestible than unfermented soyabeans.49

Tempeh is the product of a mixed fermentation process involving yeasts, molds, various microorganisms, and Gram-negative bacteria, and lactic acid,50 although the dominating constituent is Rhizopus oligosporus.51 The two processes that manufacture tempeh from raw soyabeans are described in Fig. 4.52

Tofu

Tofu is a well-known meat substitute made from soyabeans containing many nutrients like calcium, iron, and protein. Tofu is made by coagulating soya milk with CaSO4 or MgCl2, and has approximately 8% protein, 4–5% lipids, 2% carbohydrates, and about 1% dietary fiber content on a fresh weight basis.53 Vital vitamins and minerals can be added to tofu, so that it can provide a variety of nutritional and physiological benefits.54,55,56 The manufacturing procedure is described in Fig. 5.57

Kinema

Kinema is a fermented food that is alkaline and sticky due to Bacillus fungus being used during fermentation. On a dry weight basis, kinema has 62% moisture and comprises around 7% ash, 17% fat, 28% carbohydrate, and 48% protein.58 The manufacture of kinema is described in Fig. 5.59,60,61,62

Seitan

Wheat gluten (also called wheat meat or seitan) is a popular meat replacement composed of gluten isolated from wheat. Seitan has a consistency comparable to meat,63 and is used in vegan substitutes for burgers, sausages, schnitzel, minced meat, and nuggets. Additionally, most nations have wheat as an indigenous grain, making seitan production feasible worldwide.

Seitan is prepared by adjusting the wheat flour mixture's water content to between 40 and 80 (w/w%) to activate the gluten, and then the mixture is extruded into sheets to remove the starch, leaving only the gluten. The sheet stretches to impart directionality to the fiber structure throughout the process. Finally, with a humidity of around 75% and a temperature of about 75–120°C, the produced sheets are dried by heating. After drying, the gluten is crushed into a powder to obtain the seitan.64

Edamame

Edamame is made from immature soyabeans. The pods are cooked or steamed before serving with salt and other seasonings.65 Edamame contains 73% water, 12% protein, 9% carbs, and 5% fat, and has 121 calories per 100 grams. It is high in protein, dietary fiber, and minerals like folate, manganese, and vitamin K. Edamame has 361 mg of omega-3 fatty acids and 1794 mg of omega-6 fatty acids in its fat composition.66

Green soyabean pods are harvested before they mature (about 35–40 days after the crop blooms),67 and are boiled, steamed, or microwaved. Before boiling or steaming, the pods’ ends are chopped off. Salt is added for flavor by either dissolving it in boiling water before adding the soyabean pods or after cooking. Fresh edamame should be consumed the same day it is harvested, since taste deterioration can occur in as little as 10 h, and will remain for 3 days in the refrigerator. If the pods are to be kept fresh, they should be moist to avoid discoloration and withering.67

Miscellaneous

Sweet lupine seeds may make vegan meat alternatives. Meatless (a product of Meatless, Netherlands) is composed of lupine or wheat68 in various forms, flavors, and colors. Many additional meat substitutes made from lupine are available, but have not penetrated key market groups.

In the United States, rice burgers and sausages called risofu (a term formed from the Italian word for rice, riso, and tofu) were inspired by the Shan region of Thailand, which produces rice-based tofu. Risofu combines brown, wild, and white rice to acquire maximum nutrients.63

The combination of edible oils, thickening agents, cereals, rice, and algae may serve as a forerunner to vegan meat substitutes. For example, the Germans produce remis algen.69 Another example is paneer or Indian cottage cheese made from cow or buffalo milk, and is prevalent in the Indian subcontinent and rich in nutrients.

Mass Production Techniques for Plant-Based Meat Analogs

Thermo-Extrusion

Processing techniques aim to construct plant-based or whole-muscle meat alternatives with the feel of real meat.70,71 Thermo-extrusion is a frequently used method due to its low cost, energy efficiency, adaptability, and excellent productivity. It is the primary processing method employed to convert plant proteins into structured fibrils for later meat substitute products. Thermo-extrusion may be low-, intermediate-, and high-moisture extrusions.72

Thermo-extrusion (Fig. 6) is a multipurpose procedure that includes expansion, shaping, heating, deaeration, homogenization, compression, shearing, hydration, and mixing. At elevated temperatures (140–180°C) and moderate to high moisture concentrations (40–80%), extrusion is carried out through a complicated shearing process by texturizing the protein and later forming fiber structures.73 These circumstances allow precise control over the product expansion and protein gelation, batter shape, fat emulsification, and particle restructuring.74 The extrusion process results in the micro-coagulation and fibrillation of protein components.

High-Temperature Conical Shear Cell

The high-temperature conical shear cell is a cone-in-cone device with a movable base cone. The space between the two cones is sealed to stop steam from escaping during heating, with temperatures ranging from 95 to 140°C.75 The method produces fibrils by combining pea protein–wheat gluten and soya protein–wheat gluten. The mixture is heated continuously for 15 min, and then cooled to 25°C. The foods are kept at room temperature for at least 1 h to create structurally stable fibers while enclosed in a plastic bag. Soya protein blends treated at 110°C and 120°C have a mechanical strength equivalent to chicken meat, whereas pea protein blends at 140°C have comparable strength to soya protein blends.76

Cultured Meat Production

This section discusses the feasibility of using tissue and genetic engineering methods to create edible animal meat and offering distinct environmental and social advantages over regular meat. Since cultured meat production is not butchered, it is feasible to have meat alternatives in a range of chicken, beef, and fish varieties, and later expanded to other options.7 This topic is of interest to engineers because cultured meat production is a practical application of tissue and genetic engineering, with fewer significant technological difficulties than many clinical applications.

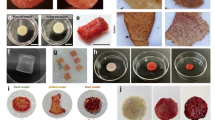

Skeletal muscle tissue constitutes the majority of edible animal meat. Using skeletal muscle tissue engineering methods to generate edible meat goes back decades, although few have researched it seriously.77 In vitro manufacturing approaches may be broadly classified into scaffold-based and self-organizing strategies.

Proliferating myoblasts (i.e., skeletal stem cells), seeding them to a scaffold or carriers like a collagen meshwork, and then perfusing them with a culture medium in a fixed or rotating bioreactor, are all part of the scaffold-based technique. When exposed to various environmental stimuli, these cells fuse into myotubes and eventually differentiate into myofibers.78 Myofibers produced through this process may subsequently be cooked and eaten like meat. A scaffold-based technique may be appropriate for boneless meals like hamburgers or sausages; however, it is incompatible with the manufacture of highly defined meats like steaks.79

Benjaminson et al.5 employed the self-organizing approach and were the first scientists to use tissue-engineered approaches for meat production. They cultivated goldfish skeletal muscle explants for 7 days in varied circumstances, and discovered an increase in its surface area from 5.2% to 13.8%. When explants were placed in a culture containing goldfish skeletal muscle cells, their surface area increased by 79%. Explants benefited from having all the cells that comprise muscle suitably closely resembling the in vivo structure. However, the absence of blood circulation in these explants precludes significant development since cells become necrotic when isolated from a source of nutrients.

Meat from genetically modified organisms and cloned animals also qualify as cultured meat. Genetically modified organisms have their genes altered through genetic engineering to contain DNA from another organism. This technique is extensively used to generate crops modified to be advantageous compared with their counterparts.40 Animal cloning is a complex process to produce species with the exact genetic traits of its parent. So far, sheep, pigs, goats, cattle, and rabbits have been cloned but never consumed.80

In-vitro Meat Production Techniques

Scaffolding Technique

Separating embryonic myoblasts from agricultural animals such as cattle, sheep, and pigs, and allowing them to develop in a stationary or rotating bioreactor using a plant-derived growth medium, would be required for a scaffold-based in vitro meat production system. These cells would divide and redivide for weeks or months, eventually transforming into muscle fibers on a scaffold within the bioreactor.78,81

A large-scale bioreactor capable of mass culturing meat has yet to be designed and built.4 Muscle creation requires using a circulatory system to provide nutrients and oxygen to growing cells or fibers while eliminating metabolic waste. Although tiny pieces of muscle obtain sufficient nutrients and oxygen through diffusion, cultured muscles with built-in blood arteries for oxygen and nutrition supply have not been developed.82

Although several cell culture methods are already accessible, the most challenging step in producing in vitro meat is identifying the optimal culture medium composition. The medium should be inexpensive, made entirely of food-grade components, widely accessible in large quantities, and effective in maintaining and encouraging muscle cell development, proliferation, and differentiation.4 Figure 7 describes the outline of the scaffolding technique of in vitro meat production.

Culture Media and Growth Factors

A culture medium should sustain and encourage development while readily accessible, inexpensive, and edible. Media with nutrients like amino acids, fatty acids, vitamins, trace minerals, and extracellular vesicles are essential for cell growth. Along with antibiotic/antimitotic combinations, certain cultures need an embryo extract.83,84

Muscle cells are the primary source of insulin-like growth factor 1 and are necessary to generate in vitro meat. Scientists often increase myoblast differentiation and fusion by lowering mitogenic growth factor levels. Proliferating cells subsequently start generating insulin-like growth factor 2, which causes differentiation and the formation of myotubes.85 Although a certain proportion of growth factors, inhibitors, and metabolic moderators are involved, it is often unclear which serum components are primarily responsible for cell growth.86

Similar to the culture medium, the scaffold composition is related to in vitro meat production. Numerous biomaterials, both synthetic and animal-derived, have been tested. As animal-derived scaffolding, like collagen, closely matches the original in vivo micro-environment, differentiated myoblasts choose to align, compress, and form a muscle fiber.87 The most successful efforts to generate in vitro meat have employed collagen-based scaffolds,88 whereas efforts to employ synthetic biomaterials have encountered difficulties in contracting the tissue.89

Bioreactor

The importance of a bioreactor layout in tissue regeneration has been discussed previously.90,91 Static bioreactors have been extensively utilized and entail seeding cells on a scaffold, followed by adding suitable growth media and culturing in an incubator. In vitro meat production will need the development of novel bioreactors capable of stimulating tissue growth and maintaining low shear and uniform perfusion at high volumes. Rotating bioreactors have been used extensively in skeletal muscle tissue engineering research.

The bioprocess is divided into four stages: cell multiplication, differentiation of cells, product production, and waste valorization. The complexity of the environment in which muscle cells proliferate and differentiate distinguishes in vitro meat bioprocessing from existing bioprocesses.92

The rotating wall vessel bioreactor spins at a rate that balances centrifugal force, drag force, and gravity force, and submerges the three-dimensional culture in the medium, assisting in developing tissue with a comparable structure to that found in vivo.93 The biomechanical forces help create a laminar flow of the medium, which improves diffusion and achieves a high mass transfer rate with a low shear stress level.

Direct perfusion bioreactors are another type better suited to scaffold-based cultivation. The medium in this scenario runs via a porous scaffold, and gas exchange occurs in an external fluid loop.94 This kind of bioreactor has a high mass transfer rate and significantly low shear stress.

Self-Organizing Technique

A more ambitious method for producing highly structured in vitro meat is to use explanted animal muscle tissue. It includes the creation of self-organized muscle tissue79 or the in vitro proliferation of existing muscle tissue.5

Benjaminson et al.5 investigated whether homologous adult muscle tissue cells could bind and grow on a substrate. Slices of goldfish tissue were chopped and centrifuged to make pellets, and were put in Petri plates with a nutrition mixture and cultivated for 7 days. Benjaminson et al. examined a range of growth media (including fetal bovine serum, fish meal extract, and several mushroom extracts) to understand how each aided in developing explant muscle tissue, and identify possible substitutes for fetal bovine serum. After 2 weeks in culture, 81% of 48 cultures revealed tissue adhesion to the culture vessel, 63% displayed self-healing, and 74% displayed cell proliferation. When fetal bovine serum was utilized as the nutritional medium, the explanted tissue increased by around 14% and by more than 13% when maitake mushroom extract was utilized. After a week in a culture containing goldfish skeletal muscle cells, the surface area of the explants increased by 79%. The explants and newly formed tissue resembled fresh fish fillets, and were marinated in olive oil and garlic and deep-fried before being submitted to a sensory panel for evaluation. The sensory panel reported that the explants and newly grown tissue looked and smelled edible.95,96,97

Li et al.98 established a protocol for the isolation and proliferation of porcine muscle cells. The muscles were cut into small pieces, centrifuged to isolate the cells and make pellets, which were placed in Petri dishes to proliferate using a growth medium of fetal bovine serum and penicillin–streptomycin, and a differentiation medium of horse serum. The proliferation assessment shows around 70% proliferation in a week.

Recently, Wang et al.99 harvested goat skeletal muscle cells and proliferated them up to 80% using a growth medium of fetal bovine serum and a differentiation medium of horse serum. The above studies prove the potency of fetal bovine serum and horse serum in proliferating muscle cells. Research is required to establish protocols using the reagents against various animal muscle cells for in vitro meat production using the self-organizing technique.

3D/4D Organ or Bio-Printing

Three-dimensional (3D) or four-dimensional (4D) organ or bioprinting (Fig. 8) is based on conventional printing principles. Computer-aided design (CAD) software is used to create the prototype of the bio-product. Cells are sprayed onto gels according to CAD, and, on culturing, the cells fuse to form the bio-product, which can have the basic cellular structure and vascularization to deliver blood.100,101,102

3D bioprinting is one of the most effective and appealing techniques for creating functionally and anatomically identical organs or tissues for regenerative tissue and organ therapeutic applications. It accurately deposits biomaterials and various cell types into a single 3D tissue architecture. 4D printing, which employs comparable technology, extends 3D printing and adds another dimension of alteration over time. The target organs or tissues are sensitive to humidity and temperature, and this technique is utilized to repair muscle, bone, and cardiovascular tissues.103

In 2021, Aleph Farms, in collaboration with The Technion, Israel Institute of Technology, successfully cultivated the world’s first rib-eye steak using 3D bioprinting. It possesses fat similar to regular meat and is claimed to be tender and juicy. The company also states it will be able to produce any kind of meat with the technology in the future.104

Biophotonics

Biophotonics is a new process that uses laser light to bind particles together. It produces “optical matter” in the form of desired structures, in which material can be deposited and held together until the light is removed. The material held can combine to form a new solid structure. The mechanics of this extraordinary property of light is still poorly understood.

The novel technology may manufacture meat if the muscle cells can fuse, and could instill features such as fat easily, compared to other techniques. Biophotonics could be an alternative to hold cells instead of adopting conventional scaffolding techniques.101 To date, red blood cells and hamster ovaries have been created using biophotonics.105

Nanotechnology

Nanotechnology aims to design a molecule-sized robot capable of manipulating matter on an atomic level that can create nearly any material from the start by assembling the molecules precisely. This could apply to producing meat, although this is financially and technologically unfeasible at the time.101

Nanotechnology could preserve meat without reducing nutrients and extend shelf life.106,107 To improve male fertility, selective breeding can be achieved by isolating viable sperms through magnetic nanoselection, whose application could extend to animals.108 Nanodevices, coupled with anti-microbial particles, can track genuity, expiry date of meat products, and meat spoilage, and provide safe standards.109,110,111

Nanotechnology offers great potential, and future attempts in meat production will need to overcome the limits of current approaches by developing edible and inexpensive cultured cells, scaffolds, culture media, and growth hormones.

Genetically Modified Organisms and Cloned Animals

Genetically modified organisms may be considered the third class of artificial meat. Despite their similarities, animals whose genomes have been changed purposely in a laboratory should be considered artificial.

Cloned animals are the fourth class of artificial meat. Cloning is just a scientifically aided approach to producing identical descendants. As it is a man-made procedure, the meat may be seen as artificial.

Genetic modification of animals has been discussed previously,40 and it may mitigate the environmental effect of conventional meat production. Although feasible theoretically and has been tested, no genetically engineered animals have been authorized for human consumption.

Animal cloning allows the spreading of existing genetics by increasing the number of animals with a specific genotype and cutting carbon emissions.112 Cloning animals with good genetics could complement other strategies like genetic manipulation, but might have some negative consequences relating to animal conservation. However, the cloning process is not without defects, with some acquiring deformities, such as large/abnormal offspring syndrome and immature deaths directly resulting from the cloning technology.22

A colossal challenge in the industrial uptake of GMOs is their licensing. Although taming genetically modified animals has been a subject of recent research, the idea's critical reception has been hostile and has not yet been approved.113,114 Such impediments negatively affect investment returns, although no significant infrastructure investment is needed to farm genetically modified livestock. The significant cost involved is disseminating the product within the population.115

Nutritional Value

Any in vitro meat product must at least meet the nutritional content of regular meat to compete in the market. Along with a high protein level and complete amino acid profile, regular meat has various additional beneficial elements, including vitamins, minerals, and bioactive substances.116

The growth medium must be supplied with nutrients not produced by muscle cells. For example, vitamin B12 is produced exclusively by certain gut-colonizing bacteria and found exclusively in regular meat. To be present in an in vitro meat product, vitamin B12 created commercially would need to be supplied. Iron is plentiful in regular meat in the heme form, which is present in myoglobin and hemoglobin.117 Ferric ions associated with transferrin (a blood-plasma protein) will probably need to be added to the culture medium to provide iron in an accessible form to the muscle cell mitochondria to be incorporated into heme, resulting in the synthesis of myoglobin.118 However, transferrin levels will need to be controlled to avoid excessive amounts of free ferric or ferrous ions, promoting the formation of harmful reactive oxygen species.119 Myoglobin concentrations in the muscle cells are to be kept low until a significant population of myotubes is created, which might also assist in calculating the optimal growth time necessary before harvesting in vitro meat.120

Productions Costs and Market Size

Compared to a $1 beef hamburger that can be made in no time, the first in vitro hamburger in 2013 cost over $300,000 and took 2 years to develop.7 Ever since, production technologies have developed immensely to reduce costs and commercialize in the future. Table II describes the recently predicted production costs by companies around the world.

The estimated global market for cultured meat will be $214 million by 2025 and $593 million by 2032,121 with entrepreneurs aggressively establishing start-ups. However, its market falls short of plant-based analogs, whose value was estimated to be $4.6 billion in 2018 and $85 billion in 2030.122

Bryant et al.123 asked participants about their willingness to replace regular meat with cultured meat in their diet, and 64.6% of participants were willing to try cultured meat, 49.1% were willing to buy it regularly, and 48.5% were ready to replace regular meat in their diet. However, this study is contradicted by Hocquette et al.,124 where the majority were not willing to buy cultured meat. Similarly, studies by Bekker et al.125 and Verbeke et al.126 showed positive results, whereas participants in other studies by Verbeke et al.15,127 and Siegrist et al.128 were less optimistic. The studies were conducted in different countries and with participants from different cultures and backgrounds. When these and similar other studies are put together, the key to boosting cultured meat’s market size is revealed: science-backed advertising! Cultured meat’s acceptance will vary across cultures, genders, and most importantly, depending upon people’s awareness. Cultured meat pioneers must focus on sharing information and building trust in consumers. Knowledge is power!

Regulatory Pathways

Food regulatory pathways ensure safety for consumers, and cultured meat products are likely to be regularized as novel foods. Schneider141 and Petetin142 argued that regulations were inadequate at the time of writing to deal with the technology without significant improvement in the United States and European Union, respectively. Schneider believes that conventional meat is not a natural version of in vitro meat, and the appropriate regulation depends upon the production technique. Petetin speculates on the benefits of the 2013 draft, of which a version was approved by the European Union removing equivalence considerations existing in previous regulations. However, she argued that genetically modified organism products are not cultured meat, which the European Union adopted in 2015 instead of regulating these type of products.34 It is vital to establish that all cultured meat is of animal origin, although animal cells are only a tiny proportion of the total materials. On acceptance, the regulation would involve many organizations, including livestock, the environment, food, and local authorities.

The use of the word ‘meat’ is debated; a belief exists that the word is meant to come from a real animal, and the use of the word for laboratory technology is misuse and causes confusion. If so, should cultured meat be called ‘meat’? If not, what should it be called that would not distance itself from conventional meat? The answer is likely to differ between countries and interests!

A potential food fraud: attempts to sell cultured meat as regular meat and vice-versa, could lead to many regulatory concerns. Also, the possibilities of mislabeling products and producing meat from non-livestock species (human, dangerous animals, insects, etc.) could lead to serious health issues as research reports that consuming cancerous in vitro cell lines may transfer DNA.143,144 Evidence of cultured meat being safe long term is minimal, as it is challenging to foresee possible risks.

Cultured meat is subject to scientific uncertainty: it might have positive and negative consequences. The danger of cultured meat being potentially toxic and having irreversible consequences affects its market. In contrast, delaying commercialization would also attract doubt.145 The technology also lacks a protocol for choosing the right type of cells, and currently relies only on stem cells or precursor cells for meat production.

Currently, regulatory frameworks are unclear and in progress. Various regulatory approvals are required, backed by research, before cultured meat hits the market for the public.

Challenges and Prospects

Although artificial meat offers distinct benefits over conventional meat, several ambiguities over its acceptability, manufacturing costs, and societal acceptance persist. Also, popular cultured meat production techniques possess drawbacks that hinder their use in specific applications. Table III describes the advantages and disadvantages of the cultured meat production techniques mentioned in this paper.

In contrast to conventional meat, artificial meat is colorless. Consumers do not appreciate this significant disparity. Natural colors like sugar beet or saffron may be added,146 and, as previously discussed, including heme present in myoglobin and hemoglobin proteins can add nutritional value but also impart a red color to cultured meat, making it resemble red meat. Another drawback is the absence of texture. Transglutaminase may improve the texture, although it establishes odd chemical linkages and creates non-conventional amino acids. However, these compounds may be not be digested and so present a threat to human health. Thus, more research is required to elucidate involving transglutaminase in artificial meat.

Production costs remain high, particularly serum from animal blood, which is required to enhance in vitro cell development. So far, all trials on in vitro meat have been conducted on a small-scale meat production basis; energy expenses are considerably reduced in laboratories when a tiny bioreactor is used. However, it is unclear how large-scale manufacturing might affect the end products’ prices and time to market. Humbird147 estimates the market price for premium quality in vitro meat to be a minimum of $50/kg, whereas large-scale batch processes using low-cost media could provide meat under $25/kg.

Livestock is responsible for a significant proportion of greenhouse gas emissions. A potential benefit of cultured meat is its help in reducing methane emissions. Cattle farming releases methane, carbon dioxide, and nitrous oxide, whereas in vitro meat releases carbon dioxide primarily due to the use of fossil energy.148 However, Mattick et al.149 inconclusively contradicts this analogy, whereas Lynch et al.150 state that global warming may reduce initially, but not long term as carbon dioxide stays in the atmosphere.

In vitro meat will need less land than conventional meat production, although this would not be advantageous as livestock are vital in maintaining soil fertility. However, energy resources (electricity, fossil fuel, etc.) requirements will increase on large-scale production. Therefore, production techniques utilizing natural energy resources like solar, wind, hydrothermal, geothermal, biofuel, and tidal energy are to be developed, replacing preceding approaches.

Since cultured meat is a technical product, it cannot be assumed that the present customer views it as natural, and is likely the most significant disadvantage. Other concerns include the dangers of consuming untested materials, the possibility of misusing technological advances to culture human muscle tissue resulting in victimless cannibalism, people undervaluing cultured meat, disgust towards cultured meat (the ’yuck’ factor), and many more.151

Although mass production techniques for plant-based meat analogs have been developed, in vitro meat is non-equivalent to conventional meat without similar texture, flavor, and nutritional content. Currently, the product does not meet consumers’ expectations, making mass production an aspect for future discussion. Therefore, the in vitro meat industry is in its infancy, requiring procedures to be optimized through extensive research and challenges relating to cost, perception, nutrition, flavor, texture, energy consumption, environmental impact, and availability being addressed before mass production can become a reality.

The societal challenges surrounding cultured meat have been framed primarily in ethics and consumer acceptability. However, they are insufficiently broad for investigating politics, which will benefit society and address genuine concerns and barriers.

Academic ethical literature provides compelling arguments favoring cultured meat, especially when a philosophical approach is used.152 Typically, these focus on a successful cultured meat system's environmental and animal welfare advantages. While some say that making cultured meat is a moral obligation, others suggest that vegetarianism may be preferable.153,154 Negative perspectives suggest that cultured meat perpetuates the present fetishization of meat, and, because of its high cost, may result in a guilt-free meat-eating elite operating at the expense of the poor.155 Others have voiced concerns about the notion as a whole, claiming that resorting to biotechnology to address ethical quandaries is damaging, and that cultured meat is a dreadful illustration of the decontextualization and molecularization of viability.156

A second significant area of research has been the public's perceptions of cultured meat. Occasionally, a few limit this to a question of consumer acceptability. However, this issue should be phrased generally, to include more political and personal opinions, ambiguities, and adverse effects of the societal ramifications of cultured meat. Existing research on attitudes toward cultured meat uses several approaches, but they all agree on one point: they discover a spectrum of perspectives ranging from highly supportive to highly hostile, with many in between. According to social media analyses and comments on news stories on cultured meat, the seeming unnaturalness of cultured meat may be a source of disagreement.

While these ethical and consumer acceptability concerns are critical, it is also critical to expand the understanding of cultured meat to include the associated political, social, and institutional ramifications. These concerns are mutually reinforcing, and they must be examined concurrently. Numerous arguments favoring cultured meat and other substitute proteins have stressed their ability to disrupt and mitigate the adverse effects of conventional animal agriculture. However, up to now, cultured meat has lived only in promissory tales rather than in actual, material forms. It is unknown what the future of cultured meat will look like, what inputs will be needed, or their environmental and ethical footprints.

Conclusion

Artificial meat technologies are advancing at a breakneck pace to increase customer expectations for health, environmental sustainability, and animal welfare. The manufacture of small-scale cultured meat products of edible quality should shortly be feasible, although large-scale production still seems challenging and is likely to take time, even if possible. Artificial intelligence-assisted cultured meat production seems to be one of the potential answers. It is impossible to close the demand–supply imbalance via traditional meat production with the rising demand for meat. Cultured meat production should be pushed to supply customers with environmentally friendly and disease-free meat.

At the moment, the only products generally accessible to customers are meat substitutes made from plant proteins. While traditional meat production involving animals is unlikely to be phased out, the sector will encounter a complex commercial and regulatory climate, resulting in industry-wide changes.

Despite its current hefty price, cultured meat's manufacturing costs will likely fall soon. Product-oriented advertising will be more successful in attracting consumers to this unique product than emphasizing the advantages of the manufacturing process. However, cultured meat will not compete with alternative meat replacements, such as plant-based foods, currently on the market, and have a lower consumer acceptance rate.

This unique product has significant obstacles ahead, with societal acceptability and manufacturing costs at the forefront before becoming a commercial reality. Numerous technologies are not yet suitable for commercial use and are battling regulatory laws. Although cultured meat attracts animal rights activists, a few animals must still be killed to gather their cells. Extensive research, support, and investment from government authorities and industries are needed to translate artificial meat into a large-scale industry and to replace conventional meat production.

References

“World Population Clock: 7.9 Billion People (2022) - Worldometer”, URL: https://www.worldometers.info/world-population/, Date Accessed: 07-03-2022.

M. Roser, H. Ritchie and E. Ortiz-Ospina, Our world data, 2013, URL: https://ourworldindata.org/world-population-growth, Date Accessed: 07-03-2022.

K. Levine, National public radio 20, (2008).

I. Datar and M. Betti, Innov. Food Sci. Emerg. Technol. 11, 13 (2010).

M.A. Benjaminson, J.A. Gilchriest and M. Lorenz, Acta Astronaut. 51, 879 (2002).

P.D. Edelman, D.C. McFarland, V.A. Mironov and J.G. Matheny, Commentary: In vitro-cultured meat production. Tissue Eng. 11, 659 (2005).

M. Zaraska, Washington Post (2013).

J.L. Capper, J. Anim. Sci. 89, 4249. (2011).

T.J. Key, G.K. Davey and P.N. Appleby, Proc. Nutr. Soc. 58, 271 (1999).

B. Macintyre, Test-tube meat science’s next leap. Weekend Aust. 20, 16 (2007).

CTBUH 8th World Congress on Tall & Green: Typology for a Sustainable Urban Future, D. Despommier, (2008), 311-318.

D. Siegelbaum, Time (2008).

F. A. O. L. L. Shadow, FAO Rome, Italy (2006).

A. McLeod, World livestock 2011-livestock in food security. (Food and agriculture organization of the united nations (FAO), 2011).

W. Verbeke, F. J. A. Pérez-Cueto, M. D. d. Barcellos, A. Krystallis and K. G. Grunert, Meat Sci. 84, 284 (2010).

A.C. Hoek, P.A. Luning, P. Weijzen, W. Engels, F.J. Kok and C. de Graaf, Appetite 56, 662 (2011).

A.C. Hoek, P.A. Luning, A. Stafleu and C. De Graaf, Appetite 42, 265 (2004).

A.C. Hoek, M.A.J.S. van Boekel, J. Voordouw and P.A. Luning, Food Qual. Prefer. 22, 371 (2011).

C. Mattick and B. Allenby, Issues Sci. Technol. 30, 64 (2013).

J.N. Goodwin and C.W. Shoulders, The future of meat: a qualitative analysis of cultured meat media coverage. Meat Sci. 95, 445 (2013).

K.R. Brooks and J.L. Lusk, Appetite 57, 483 (2011).

K. Verzijden K. and A. Lawyers. "EFSA UPDATE ON CLONING IN RELATION TO FOOD PRODUCTION1." (2012).

P. Kumar, N. Sharma, S. Sharma, N. Mehta, A.K. Verma, S. Chemmalar and A.Q. Sazili, J. Anim. Sci. Technol. 63, 693 (2021).

G. Jairath, G. Mal, D. Gopinath and B. Singh, A holistic approach to access the viability of cultured meat: a review. Trends Food Sci. Technol. 110, 700 (2021).

P. Kumar, M.K. Chatli, N. Mehta, P. Singh, O.P. Malav and A.K. Verma, Crit. Rev. Food Sci. Nutr. 57, 923 (2016).

Joshi, V. K. and Satish Kumar. "Meat analogues: plant based alternatives to meat products-a review." Int. J. Food Ferment Technol. 5, 107 (2015).

A. Orzechowski, J. Integr. Agric. 14, 217. (2015).

M.W. Fowler and A.H. Scragg, Natural products from higher plants and plant cell culture. Plant Cell Biotechnol. 18, 165 (1988).

G. Wenzel, O. Schieder, T. Przewozny, S.K. Sopory and G. Melchers, Theor. Appl. Genet. 55, 49 (1979).

I.K. Vasil, F. Constabel and J. Schell, Cell culture and somatic cell genetics of plants (Academic Press, New York, 1984).

R. S. Chaleff, Genetics of Higher Plants: Applications of Cell Culture (CUP Archive, 1981).

S.W. Ritcbie and T.K. Hodges, Cell culture and regeneration of transgenic plants. Transgenic Plants, Eng. Util 1, 147. (1993).

E. Ramboer, B. De Craene, J. De Kock, T. Vanhaecke, G. Berx, V. Rogiers and M. Vinken, Strategies for immortalization of primary hepatocytes. J. Hepatol. 61, 925 (2014).

N. Stephens, L. Di Silvio, I. Dunsford, M. Ellis, A. Glencross and A. Sexton, Trends Food Sci. Technol. 78, 155 (2018).

L.G. Chase, U. Lakshmipathy, L.A. Solchaga, M.S. Rao and M.C. Vemuri, Stem Cell Res. Ther. 1, 1 (2010).

S. Jung, K. M. Panchalingam, L. Rosenberg and L. A. Behie, Stem Cells Int. 2012, (2012).

A. Oikonomopoulos, W.K. Van Deen, A.R. Manansala, P.N. Lacey, T.A. Tomakili, A. Ziman and D.W. Hommes, Sci. Reports 5, 1 (2015).

J. Stern-Straeter, G.A. Bonaterra, S. Juritz, R. Birk, U.R. Goessler, K. Bieback, P. Bugert, J. Schultz, K. Hörmann, R. Kinscherf and A. Faber, Int. J. Mol. Med. 33, 160 (2014).

C. Franzini-Armstrong and A. G. Engel. "Skeletal muscle: Architecture of membrane systems." Muscle. Elsevier Inc. 2, 763 (2012).

V. Eenennaam and A. Louise, Genetic modification of food animals. Curr. Opin. Biotechnol. 44, 27 (2017).

C. Zhang, R. Wohlhueter and H. Zhang, Food Sci. Hum. Wellness 5, 116 (2016).

“Genetically modified organism,” Wikipedia, URL: https://en.wikipedia.org/wiki/Genetically_modified_organism, Date Accessed: 07-03-2022.

W.H. Turnbull, J. Walton and A.R. Leeds, Acute effects of mycoprotein on subsequent energy intake and appetite variables. Am. J. Clin. Nutr. 58, 507 (1993).

A. Denny, B. Aisbitt and J. Lunn, Mycoprotein and health. Nutr. Bull. 33, 298 (2008).

“Vegetarian & Vegan Products, Meat Free Recipes & News | Quorn.” URL: https://www.quorn.co.uk/, Date Accessed: 07-03-2022.

C. W. Kolar, S.H. Richert, C.D. Decker, F. H. Steinke and R. J. Vander Zanden (1985), New Protein Foods 5, 259.

M.N. Riaz, Cereal Foods World 44, 136. (1999).

P. Dinesh Babu, R. Bhakyaraj and R. Vidhyalakshmi, World J. Dairy Food Sci. 4, 22 (2009).

M. Astuti, A. Meliala, F.S. Dalais and M.L. Wahlqvist, Tempe, a nutritious and healthy food from Indonesia. Asia Pac. J. Clin. Nutr. 9, 322 (2000).

K.H. Steinkraus, Fermented foods, feeds and beverages. Biotechnol. Adv. 4, 219 (1986).

R. Sharma and A. K. Sarbhoy, “Tempeh-a fermented food from soybean.,” Curr. Sci. 53 (1984).

M.J.R. Nout and J.L. Kiers, Tempe fermentation, innovation and functionality: update into the third millenium. J. Appl. Microbiol. 98, 789 (2005).

S.P. Stanojević, M.B. Baraé, M.B. Pesié, M.M. Milovanović and B.V. Vucelić-Radović, Acta Period. Technol. 41, 77 (2010).

B.H. Arjmandi, L. Alekel, B.W. Hollis, D. Amin, M. Stacewicz-Sapuntzakis, P. Guo and S.C. Kukreja, J. Nutr. 126, 161 (1996).

C.W Xiao Health effects of soy protein and isoflavones in humans. J Nutr. 138, 1244S (2008).

L. Azadbakht, M. Kimiagar, Y. Mehrabi, A. Esmaillzadeh, M. Padyab, F.B. Hu and W.C. Willett, Am. J. Clin. Nutr. 85, 735 (2007).

A. K. Bakshi, V. K. Joshi, D. Vaidya and S. Sharma, Processing and Preservation of Fruits of Himalayan Region; Food Processing and Preservation Part I (Jagmander book agency, New Delhi, 2013).

H.-j Wang and P.A. Murphy, Isoflavone content in commercial soybean foods. J. Agric. Food Chem. 42, 1666 (1994).

J.P. Tamang, P.K. Sarkar and C.W. Hesseltine, Traditional fermented foods and beverages of Darjeeling and Sikkim–a review. J. Sci. Food Agric. 44, 375 (1988).

P.K. Sarkar, P.E. Cook and J.D. Owens, World J. Microbiol. Biotechnol. 9, 295 (1993).

P.K. Sarkar, J.P. Tamang, P.E. Cook and J.D. Owens, Kinema–a traditional soybean fermented food: proximate composition and microflora. Food Microbiol. 11, 47 (1994).

P.K. Sarkar and J.P. Tamang, The influence of process variables and inoculum composition on the sensory quality of kinema. Food Microbiol. 11, 317 (1994).

S. Kurt. "Worldwide alternatives to animal derived foods–overview and evaluation models." Solution to global problems caused by livestock. University of Natural Resources and Life Sciences. Vienna, Austria (2012).

J. Leonard. Cooking with seitan: the complete vegetarian" wheat-meat" Cookbook. Penguin, 1994.

D. Johnson, S. Wang and A. Suzuki, Energy (Kcal) 582, 573 (2000).

“Edamame, frozen, prepared Nutrition Facts & Calories.”, URL: https://nutritiondata.self.com/facts/vegetables-and-vegetable-products/9873/2, Date Accessed: 07-03-2022.

Shanmugasundaram, S. "Vegetable Soybean: research needs for production and quality improvement." (1991).

“Innovative functional foods based on sweet lupin protein for cardiovascular prevention ,” European Commission, 2016, URL: https://cordis.europa.eu/project/id/285819, Date Accessed: 07-03-2022.

“Future Food - Vegetarian Meat,” 2021, URL: https://www.futurefood.org/tofu/index_en.php, Date Accessed: 07-03-2022.

B.L. Dekkers, R.M. Boom and A.J. van der Goot, Structuring processes for meat analogues. Trends in Food Sci. Technol 81, 25 (2018).

K.D. Mattice and A.G. Marangoni, Comparing methods to produce fibrous material from zein. Food Res. Int. 128, 108804 (2020).

H. Akdogan, High moisture food extrusion. Int. J. Food Sci. Technol. 34, 195 (1999).

F. Wild, M. Czerny, A.M. Janssen, A.P. Kole, M. Zunabovic and K.J. Domig, Agro FOOD Ind. Hi Tech 25, 45 (2014).

J.C. Cheftel, M. Kitagawa and C. Queguiner, Food Rev. Intl. 8, 235 (1992).

G.A Krintiras, J. Gadea Diaz, A.J. Van Der Goot, A.I. Stankiewicz and G.D. Stefanidis (2016), J. Food Eng., 169, 205.

F.K.G. Schreuders, B.L. Dekkers, I. Bodnár, P. Erni, R.M. Boom and A.J. van der Goot, J. Food Eng. 261, 32 (2019).

Churchill WS. Thoughts and adventures. Rosetta Books; 2016.

Freshney, R. Ian and Gordana Vunjak-Novakovic, Culture of cells for tissue engineering. John Wiley & Sons, 2006.

R.G. Dennis and P.E. Kosnik, Excitability and isometric contractile properties of mammalian skeletal muscle constructs engineered in vitro. Vitr. Cell. Dev. Biol. 36, 327 (2000).

P. Dolma, A. Ali, R. C. Sobti and A. Chauhan, in Adv. Anim. Exp. Model. (Academic Press, 2022), pp. 53–67.

J.S.H. Seah, S. Singh, L.P. Tan and D. Choudhury, Crit. Rev. Biotechnol. 42, 311 (2021).

A. Skardal, J. Zhang and G.D. Prestwich, Biomaterials 31, 6173 (2010).

H. Aswad, A. Jalabert and S. Rome, BMC Biotechnol. 16, 1 (2016).

D. Brunner, J. Frank, H. Appl, H. Schöffl, W. Pfaller and G. Gstraunthaler, ALTEX-Alternatives Anim. Exp. 27, 53 (2010).

J.R. Florini, K.A. Magri, D.Z. Ewton, P.L. James, K. Grindstaff and P.S. Rotwein, J. Biol. Chem. 266, 15917 (1991).

F. Mannello and G.A. Tonti, Stem Cells 25, 1603 (2007).

M.L.P. Langelaan, K.J.M. Boonen, R.B. Polak, F.P.T. Baaijens, M.J. Post and D.W.J. van der Schaft, Trends Food Sci. Technol. 21, 59 (2010).

C. Snyman, K. Goetsch, K. Myburgh and C. Niesler, Frontiers in Physiology 4, (2013).

W. Bian and N. Bursac, Biomaterials 30, 1401 (2009).

I. Martin, D. Wendt and M. Heberer, The role of bioreactors in tissue engineering. Trends Biotechnol. 22, 80 (2004).

L.E. Freed and G. Vunjak-Novakovic, Tissue engineering bioreactors. Princ. Tissue Eng. 2, 143 (2000).

A.C. Schnitzler, A. Verma, D.E. Kehoe, D. Jing, J.R. Murrell, K.A. Der, M. Aysola, P.J. Rapiejko, S. Punreddy and M.S. Rook, Biochem. Eng. J. 108, 3 (2016).

R.L. Carrier, M. Papadaki, M. Rupnick, F.J. Schoen, N. Bursac, R. Langer, L.E. Freed and G. Vunjak-Novakovic, Biotechnol. Bioeng. 64, 580 (1999).

R.L. Carrier, M. Rupnick, R. Langer, F.J. Schoen, L.E. Freed and G. Vunjak-Novakovic, Perfusion improves tissue architecture of engineered cardiac muscle. Tissue Eng. 8, 175 (2004).

Z. F. Bhat, H. Bhat and S. Kumar, “Cultured meat—a humane meat production system,” Princ. Tissue Eng., 1369 (2020).

T Hukill, “Would you eat lab-grown meat,” Alternet. Retrieved May 13, 2008 (2006).

I Sample, “Fish fillets grow in tank,” New Sci. Retrieved May 13, 2008 (2002).

B.-J. Li, P.-H. Li, R.-H. Huang, W.-X. Sun, H. Wang, Q.-f Li, J. Chen, Wu. Wang-jun and H.-L. Liu, Isolation, culture and identification of porcine skeletal muscle satellite cells. Asian Australas. J. Anim. Sci. 28, 1171 (2015).

Y. Wang, X. Xiao and L. Wang, In vitro characterization of goat skeletal muscle satellite cells. Anim. Biotechnol. 31, 115 (2020).

T. Boland, V. Mironov, A. Gutowska, E.A. Roth and R.R. Markwald, “Cell and organ printing 2: fusion of cell aggregates in three-dimensional gels,” Anat. Rec. Part A Discov. Mol. Cell. Evol. Biol. 272A, 497 (2003).

P.D. Hopkins and A. Dacey, Vegetarian meat: could technology save animals and satisfy meat eaters? J. Agric. Environ. Ethics 21, 579. (2008).

Aldhous PE. Print me a heart and a set of arteries. New Sci., 15, (2006).

M. Javaid and A. Haleem, Clin. Epidemiol. Glob. Heal. 7, 317. (2019).

“Aleph farms and the technion reveal world’s first cultivated ribeye steak.”, URL: https://www.prnewswire.com/il/news-releases/aleph-farms-and-the-technion-reveal-worlds-first-cultivated-ribeye-steak-301224800.html, Date Accessed: 07-03-2022.

J. Mullins, The stuff of beams. New scientist. 2551, 44 (2006).

D.K. Banerjee, A.K. Das, R. Banerjee, M. Pateiro, P.K. Nanda, Y.P. Gadekar, S. Biswas, D.J. McClements and J.M. Lorenzo, Foods 9, 432 (2020).

A.K. Das, P.K. Nanda, S. Bandyopadhyay, R. Banerjee, S. Biswas and D.J. McClements, Compr. Rev. Food Sci. Food Saf. 19, 2677 (2020).

C.L. Durfey, S.E. Swistek, S.F. Liao, M.A. Crenshaw, H.J. Clemente, R.V.K.G. Thirumalai, C.S. Steadman, P.L. Ryan, S.T. Willard and J.M. Feugang, J. Anim. Sci. Biotechnol. 10, 1 (2019).

K. Ramachandraiah, S.G. Han and K.B. Chin, Nanotechnology in meat processing and packaging: potential applications–a review. Asian-Australasian J. Anim. Sci. 28, 290 (2015).

C. Sharma, R. Dhiman, N. Rokana and H. Panwar, Front. Microbiol. 8, 1735 (2017).

T. Sikka, The ‘embodied multi-material layering’ of In Vitro meat. Techné Res. Philos. Technol. 24, 158 (2020).

L. Petetin "The revival of modern agricultural biotechnology by the UK government: what role for animal cloning?." Euro. Food Feed Law Rev., 296 (2012).

A. Bruce, D. Castle, C. Gibbs, J. Tait and C.B.A. Whitelaw, Transgenic Res. 22, 681 (2013).

C. Carlarne, From the USA with love: sharing home-grown hormones, GMOs and clones with a reluctant Europe. Envtl. L. 37, 301 (2007).

K.A. Mccoll, B. Clarke and T.J. Doran, Role of genetically engineered animals in future food production. Aust. Vet. J. 91, 113 (2013).

J.F. Young, M. Therkildsen, B. Ekstrand, B.N. Che, M.K. Larsen, N. Oksbjerg and J. Stagsted, Meat Sci. 95, 904 (2013).

C. Uzel and E. Marcel. Conrad M E "Absorption of heme iron." Seminars hematol. 35 (1998).

P. Aisen, C. Enns and M. Wessling-Resnick, Int. J. Biochem. Cell Biol. 33, 940 (2001).

G. Papanikolaou and K. Pantopoulos, Toxicol. Appl. Pharmacol. 202, 199 (2005).

S.G. Graber and R.C. Woodworth, J. Biol. Chem. 261, 9150 (1986).

R. Srutee, R.S Sowmya and S.A Uday "Clean meat: Techniques for meat production and its upcoming challenges." Animal Biotechnol. 1 (2009).

L. Sha and Y.L. Xiong, Plant protein-based alternatives of reconstructed meat: science, technology, and challenges. Trends Food Sci. Technol. 102, 51 (2020).

C. Bryant, K. Szejda, N. Parekh, V. Desphande and B. Tse, Front. Sustain. Food Syst. 3, 11 (2019).

A. Hocquette, C. Lambert, C. Sinquin, L. Peterolff, Z. Wagner, S.P.F. Bonny, A. Lebert and J.F. Hocquette, J. Integr. Agric. 14, 273 (2015).

G.A. Bekker, H. Tobi and A.R.H. Fischer, Appetite 114, 82 (2017).

W. Verbeke, P. Sans and E.J. Van Loo, J. Integr. Agric. 14, 285 (2015).

W. Verbeke, et al., ‘Would you eat cultured meat?’: consumers’ reactions and attitude formation in Belgium, Portugal and the United Kingdom. Meat Sci. 102, 49 (2015).

M. Siegrist and B. Sütterlin, Appetite 113, 320 (2017).

“Indian cell-based meat company claims it has achieved price parity.”, URL: https://vegconomist.com/companies-and-portraits/indian-cell-based-meat-company-claims-it-has-achieved-price-parity/, Date Accessed: 07-03-2022.

“Out of the lab and into your frying pan: the advance of cultured meat.”, URL: https://www.theguardian.com/food/2020/jan/19/cultured-meat-on-its-way-to-a-table-near-you-cultivated-cells-farming-society-ethics, Date Accessed: 07-03-2022.

“Will cultured meat soon be a common sight in supermarkets across the globe?”, URL: https://www.forbes.com/sites/briankateman/2020/02/17/will-cultured-meat-soon-be-a-common-sight-in-supermarkets-across-the-globe/?sh=4e275b1f7c66, Date Accessed: 07-03-2022..

“Higher Steaks Makes World’s First Cell-Based Pork Belly.”, URL: https://www.greenqueen.com.hk/higher-steaks-makes-worlds-first-cell-based-bacon-pork-belly-uk/, Date Accessed: 07-03-2022.

“Swiss start-up: laboratory meat from Zurich.”, URL: https://www.bauernzeitung.ch/artikel/markt-preise/schweizer-start-up-laborfleisch-aus-zuerich-357008, Date Accessed: 07-03-2022.

“Mosa Meats Announces it Has Reduced Production Costs by 88 Times.”, URL: https://vegconomist.com/companies-and-portraits/mosa-meats-announces-it-has-reduced-production-costs-by-88-times/, Date Accessed: 07-03-2022.

“Singapore startup Shiok Meats re-creates shrimp — in the lab.”, URL: https://www.latimes.com/food/story/2020-10-08/lab-shrimp-meat, Date Accessed: 07-03-2022.

“I tried the world’s first no-kill, lab-grown chicken burger.”, URL: https://www.theguardian.com/food/2020/dec/04/no-kill-lab-grown-chicken-burger-restaurant-israel, Date Accessed: 07-03-2022.

“When will cultured meat be on our plate?”, URL: https://www.eoswetenschap.eu/voeding/wanneer-ligt-kweekvlees-op-ons-bord, Date Accessed: 07-03-2022.

“The €250,000 lab-grown burger could be a more palatable €9 in two years.”, URL: https://www.independent.ie/business/farming/beef/the-250000-lab-grown-burger-could-be-a-more-palatable-9-in-two-years-38298335.html, Date Accessed: 07-03-2022.

“Start-up dreams of feeding world with cheap lab-cultured meat.”, URL: https://english.kyodonews.net/news/2019/07/1513306e0c18-feature-start-up-dreams-of-feeding-world-with-cheap-lab-cultured-meat.html, Date Accessed: 07-03-2022.

“Future Food Now: Asia-Pacific (#9).”, URL: https://www.getrevue.co/profile/michalklar/issues/future-food-now-asia-pacific-9-189873, Date Accessed: 07-03-2022.

Z. Schneider, Hous. L. Rev. 50, 991 (2012).

L. Petetin, Frankenburgers, risks and approval. Eur. J. Risk Regul. 5, 168 (2014).

T. Netherwood, S.M. Martín-Orúe, A.G. O’Donnell, S. Gockling, J. Graham, J.C. Mathers and H.J. Gilbert, Nat. Biotechnol. 22, 204 (2004).

S. Spisák, N. Solymosi, P. Ittzés, A. Bodor, D. Kondor, G. Vattay, B.K. Barták, F. Sipos, O. Galamb, Z. Tulassay, Z. Szállási, S. Rasmussen, T. Sicheritz-Ponten, S. Brunak, B. Molnár and I. Csabai, PLoS ONE 8, e69805 (2013).

C. Gollier and N. Treich, J. Risk Uncertain. 27, 77 (2003).

Z.F. Bhat, S. Kumar and H. Fayaz, J. Integr. Agric. 14, 241 (2015).

D. Humbird, Biotechnol. Bioeng. 118, 3239 (2021).

H.L. Tuomisto and M.J. Teixeira De Mattos, Environ. Sci. Technol. 45, 6117 (2011).

C.S. Mattick, A.E. Landis, B.R. Allenby and N.J. Genovese, Environ. Sci. Technol. 49, 11941 (2015).

J. Lynch and R. Pierrehumbert, Front. Sustain. Food Syst. 3, 5 (2019).

Z.F. Bhat and H. Bhat, Animal-free meat biofabrication. Am. J. Food Technol. 6, 441 (2011).

A.M. Dilworth, T. Dilworth and Á.A. Mcgregor, Moral Steaks? Ethical Discourses of In Vitro Meat in Academia and Australia. J Agric Env. Ethics 28, 85 (2015).

E.B. Pluhar, J. Agric. Environ. Ethics 23, 455 (2009).

G.O. Schaefer and J. Savulescu, J. Appl. Philos. 31, 188 (2014).

M. Cole and K. Morgan, Configurations 21, 201 (2013).

J. Metcalf, Parallax 19, 74 (2013).

Acknowledgements

We want to acknowledge Manipal Institute of Technology and Manipal Academy of Higher Education, Manipal, for their unconditional support in carrying out this work.

Author Contributions

TM: conceptualization, data curation, writing: original draft & editing. AL: supervision, writing: review. PS: image design.

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors hold no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mateti, T., Laha, A. & Shenoy, P. Artificial Meat Industry: Production Methodology, Challenges, and Future. JOM 74, 3428–3444 (2022). https://doi.org/10.1007/s11837-022-05316-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05316-x