Abstract

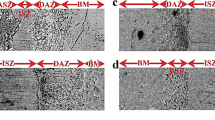

This study aimed to homogenize diffusion-brazed Nicrofer 5520 superalloy joints to achieve the most similar microstructure to the base metal. In this regard, diffusion brazing treatment was carried out at a temperature of 1120°C by using a 30-µm-thick BNi-2 interlayer. After performing the diffusion brazing and completing the isothermal solidification (bonding time of 20 min), the specimens were homogenization post-bond heat treated under a vacuum atmosphere at 1180°C and for different holding times of 4, 8, 10, 12, 14, 16, 18, and 20 h. Electron microscopy was used to investigate the microstructural evolutions and chemical composition of precipitated phases. The results revealed that by increasing the holding time, the distribution of elements in the width of the joint area became more uniform and the chemical composition became closer to the base metal. Simultaneously, the amount and volume fraction of precipitates in the diffusion-affected zone (DAZ) decreased. After 18 h in the homogenization treatment, the DAZ disappeared and only fine precipitates of nickel-rich silicide and carbide were retained at the boundary. After 20 h, the precipitates were dissolved, grains of the bond area began to grow, and the interlayer became significantly non-distinguishable from the adjacent base metal.

Similar content being viewed by others

References

S. Salari, M.S. Rahman, A.A. Polycarpou, and A. Beheshti, Mater. Sci. Eng. A 788, 139539. (2020).

H. Shah Hosseini, M. Shamanian, and A. Kermanpur, Mater. Charact. 62(4), 425. (2011).

M. Pouranvari, A. Ekrami, and A.H. Kokabi, J. Alloy. Compd. 563, 143. (2013).

J. Sun, W. Ren, P. Nie, J. Huang, K. Zhang, and Z. Li, Mater. Des. 175, 107823. (2019).

N.R. Philips, C.G. Levi, and A.G. Evans, Metall. Mater. Trans. A. 39(1), 142. (2008).

Y. Zhou, W.F. Gale, and T.H. North, Int. Mater. Rev. 40(5), 181. (1995).

Y. Yan, B. Liu, T. Xu, L. Qiao, S. Qin, J. Cao, J. Qi, J. Materiomics 1–7 (2021)

Z. Wang, G. Wang, M. Li, J. Lin, Q. Ma, A. Zhang, Z. Zhong, J. Qi, and J. Feng, Carbon 118, 723. (2017).

Y. Yan, T. Liu, J. Lin, L. Qiao, J. Tu, S. Qin, J. Cao, and J. Qi, J. Alloys Compd 883, 160933. (2021).

R. Bakhtiari, A. Ekrami, and T.I. Khan, J. Mater. Eng. Perform. 24(4), 1687. (2015).

R.K. Saha and T.I. Khan, J. Mater. Sci. 42(22), 9187. (2007).

J. Cao, Y.F. Wang, X.G. Song, C. Li, and J.C. Feng, Mater. Sci. Eng., A 590, 1. (2014).

J. Asadi, S.A. Sajjadi, and H. Omidvar, Trans. Nonferr. Met. Soc. China 31(9), 2703. (2021).

S. Ghaderi, F. Karimzadeh, A. Ashrafi, and S.H. Hosseini, J. Manuf. Process. 60, 213. (2020).

M. Paidar, K.S. Ashraff Ali, O.O. Ojo, V. Mohanavel, J. Vairamuthu, and M. Ravichandran, J. Manuf. Process. 61, 383. (2021).

H. Esmaeili, S.E. Mirsalehi, and A. Farzadi, Vacuum 152, 305. (2018).

F. Jalilian, M. Jahazi, and R.A.L. Drew, Mater. Sci. Eng., A 423(1), 269. (2006).

F. Arhami, S.E. Mirsalehi, and A. Sadeghian, J. Mater. Process. Technol. 265, 219. (2019).

A. Sadeghian, F. Arhami, and S.E. Mirsalehi, J. Manuf. Process. 44, 72. (2019).

A.Y. Shamsabadi, R. Bakhtiari, and G. Eisaabadi, J. Alloys Compd 685, 896. (2016).

A. Doroudi, A. Dastgheib, and H. Omidvar, J. Manuf. Process. 53, 213. (2020).

M. Pouranvari, A. Ekrami, and A.H. Kokabi, J. Alloy. Compd. 723, 84. (2017).

M.A. Arafin, M. Medraj, D.P. Turner, and P. Bocher, Mater. Sci. Eng. A 447(1), 125. (2007).

O.A. Idowu, O.A. Ojo, and M.C. Chaturvedi, Metall. and Mater. Trans. A. 37(9), 2787. (2006).

G. Marchese, G. Basile, E. Bassini, A. Aversa, M. Lombardi, D. Ugues, P. Fino, and S. Biamino, Materials 11, 106. (2018).

A. Malekan, M. Farvizi, S.E. Mirsalehi, N. Saito, K. Nakashima, J. Manuf. Process. 47129, 129. (2019).

D. Amiri, S.A. Sajjadi, R. Bakhtiari, and A. Kamyabi-Gol, J. Manuf. Process. 32, 644. (2018).

W.F. Gale and E.R. Wallach, Metall. Trans. A 22(10), 2451. (1991).

M. Pouranvari, A. Ekrami, and A.H. Kokabi, Materiali in Tehnologije 47, 593. (2013).

B. Zhang, G. Sheng, Y. Jiao, Z. Gao, X. Gong, H. Fan, and J. Zhong, J. Alloy. Compd. 695, 3202. (2017).

A. Malekan, M. Farvizi, S.E. Mirsalehi, N. Saito, and K. Nakashima, Mater. Sci. Eng. A 755, 37. (2019).

S. Rundqvist, An X-ray investigation of the nickel-boron system: the crystal structures of orthorhombic and monoclinic Ni4B3, United States Air Force, Office of Scientific Research (1959)

M. Witt and J. Charles, Mater. Sci. Technol. 1(12), 1063. (1985).

X.L. He, M. Djahazi, J.J. Jonas, and J. Jackman, Acta Metall. Mater. 39(10), 2295. (1991).

Acknowledgement

The authors gratefully acknowledge Dr. Mahshid Abedi from the Isfahan University of Medical Sciences for assistance with FESEM analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors have no conflicts of interest to declare and certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript. All co-authors have seen and agree with the contents of the manuscript, and there is no financial interest to report.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nasajpour, A., Mirsalehi, S.E. & Farzadi, A. Effect of Homogenization on Metallurgical Structure of Nicrofer 5520 (IN-617) Superalloy Joints Diffusion-Brazed Using a Ni–Cr–Si–B Interlayer. JOM 74, 3276–3288 (2022). https://doi.org/10.1007/s11837-022-05292-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05292-2