Abstract

The recovery of rare earth elements from spent nickel-metal hydride batteries by hydrometallurgical processing has become increasingly important in recent years. The present work investigated the effect of temperature, systems of adding the reactant, the molar ratio of sodium and lanthanum, and the initial concentration of six sulfate impurities (Ni, Co, Al, Mn, Fe, and Zn) on the crystallization of the monohydrate of sodium lanthanum sulfate double salt (NaLa(SO4)2·H2O) crystals from synthetic leachate solutions. The sodium sulfate reactant was added as an acidic solution by pumping or batchwise as a solid anhydrate salt to a pregnant lanthanum sulfate solution. Compared to precipitation with acidic sodium sulfate solution, precipitation with solid sodium sulfate yielded smaller single crystals, a greater tendency to form aggregates, and lower crystal purity. The lowest overall impurity and highest lanthanum quantity in crystals were obtained by semi-batch reactant adding performance of Na2SO4 solution at 70°C with Na/La molar ratio of 3. Real-time monitoring of the count rates of different chord length fractions clearly showed the influence of crystallization temperature on the precipitation kinetics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Globally generated electronic waste (E-waste) has grown rapidly in the past decades because of the increasing number of electronic devices per person and the growing number of users. The amount of E-waste generated globally was 54 metric tons (Mt) in 2019, and generation trend of total E-waste has increased by 9.2 Mt since 2014 reported by Forti et al.1 According to the report, the global recycling rate of E-waste in 2019 was very low; only 17% of the total E-waste was recycled.

It has been reported that 50% of the E-waste is personal electronic devices, e.g., computers, smartphones, tablets, and TVs, with the remainder being larger household appliances according to A New Circular Vision for Electronics: Time for a Global Reboot report.2 Because batteries are widely used in portable electronic devices, spent batteries represent a very large part of this generated E-waste.

Nickel metal hydride (NiMH) batteries are rechargeable batteries that are commonly used for portable devices.3 They contain many valuable materials including rare earth elements (REE). The collected and pre-treated battery waste may contain various elements originating from casings and other residuals of the battery components.4 The total mass of a single NiMH battery contains 6-10% of REE elements, as shown in Table I.5,6,7

There are concerns about the availability and supply of REE for the production of electronics and electrical devices in the future, since the availability of REE is associated with geopolitical constraints. The European Commission 8 characterized REE as the highest supply risk among critical raw materials. According to Roskill 9, lanthanum and cerium are the largest in-demand REE elements in the world. For instance, in 2017, the consumption of these REE elements alone was 85 000 tons, while the consumption of the remaining REE elements was 53 000 tons.

Therefore, an increase in the recovery rate of REE elements from E-waste will be beneficial, both economically and environmentally.

Hydrometallurgical, pyrometallurgical, or electrochemical processes can be used to recover REE and other valuable materials from spent NiMH batteries.3 Hydrometallurgical processes are widely used for the recovery of valuable materials from low-grade ore and secondary raw materials.10

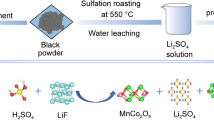

One of the most common hydrometallurgy processes involves two major process steps: leaching and precipitation.3 In the leaching stage, an acid solution is used to dissolve components from the NiMH battery, whereby the leachate solution contains REE with many other impurities. After the removal of residues from the aqueous solution by filtration, REE is separated from the bulk solution by precipitation with alkali sulfates, e.g., sodium sulfates.11

Controlling the precipitation process of REE in an acidic environment (e.g., sulfuric acid) is very complex; the interactions between different species are complicated. Optimal adjustment of pH can significantly enhance the precipitation of REE from the acid solution.12,13,14,15 In the precipitation of double salts from acidic solutions, the reactant concentrations are also crucial, as reported by Porvali et al.16

In this study, we investigated the effect of selected impurities on the precipitation of sodium lanthanum double salt crystals from a synthetic solution of NiMH batteries. Two reactant addition methods were investigated: batchwise addition of solid Na2SO4 particles and semi-batchwise addition of Na2SO4 solution to the initial lanthanum sulfate solution, where addition of solid Na2SO4 provides a higher supersaturation degree than addition of acidic Na2SO4 solution. The present work focuses on lanthanum recovery efficiency with the aim of maximizing the purity of sodium lanthanum sulfate double salt crystals. In addition to the precipitation temperature, impurity concentrations and molar ratio of sodium and lanthanum impact also the precipitation of lanthanum sodium sulfate monohydrate. The aim of the present work was to define the most appropriate process conditions for obtaining pure crystalline double salt.

Materials and Methods

Chemicals and Solutions

To investigate the crystallization of the sodium lanthanum sulfate monohydrate double salt (NaLa(SO4)2H2O), pure lanthanum oxide (La2O3, > 99.9%) and sodium sulfate (Na2SO4, > 99%) dissolved in 1 M H2SO4 were used as a synthetic solution. As shown in Table I, NiMH batteries contain several different elements. Thus, to mimic the real composition of the pregnant leaching solution of NiMH battery waste, six impurities (NiSO4·6H2O > 98%, CoSO4·7H2O > 98%, Al2(SO4)3·16H2O > 97%, MnSO4·H2O > 99%, FeSO4·7H2O > 99%, and ZnSO4·7H2O > 99%) were added to the synthetic solution. Experimental series were designed in which the molar ratio of sodium and lanthanum (Na/La) and the concentration of the sulfates (Ni, Co, Al, Mn, Fe, and Zn) were varied at two levels (Table II).

Precipitation Setup

For each precipitation experiment, 1.63 g La2O3 was dissolved in 200 ml 1 M H2SO4 with sulfate impurities at the initial concentrations. Usage of aqueous acidic Na2SO4 solution involved additional dilution of the pregnant solution, since either 2.15 g or 6.46 g sodium sulfate was dissolved in 50 ml 1 M H2SO4. It is worth pointing out that to obtain a double salt precipitate, the solution has to be acidic.

The lanthanum concentration was kept constant at 0.05 M in all experiments, and the total sulfate molar ratio varied between 0.3 mol/mol and 24 mol/mol. The experimental setup scheme is shown in Fig. 1. The mixture was stirred at a constant speed (400 rpm). When all the particles had been dissolved, the solution temperature was adjusted according to the experimental design (Table III). Anhydrate sodium sulfate (Na2SO4(s)) was dissolved in 50 ml 1 M H2SO4. Next, the acidic Na2SO4 (aq) solution was pumped into the solution. The diaphragm-metering pump (gamma-X pump) was used for pumping the sodium sulfate solution into the mixture. The pumping time used was 15 min for each experiment. After pumping, stirring of the mixture was continued for 25 min, allowing desupersaturation to occur in the solution. Thus, starting from the pumping time, the total residence time in the stirred tank was 40 min. The precipitated solid particles were separated from the mother liquor by vacuum filtration. The filter cake was washed with deionized water, and the samples were dried in an oven at 100°C for 24 h.

Real-time monitoring of count rates of different chord length fractions with two reactant feeding systems was studied with the aid of Particle Track, IC FBRM 4.4 (Focused Beam Reflectance Measurement). The FBRM made investigation of the crystallization kinetics of the sodium lanthanum monohydrate salt possible. Particle Track gives an in situ overview of the crystallization process, such as the starting time of nucleation and trends of different chord length fractions over time.

Analysis of Purity, Crystal Size, and Crystal Shape

The concentration of each element in the dry solid samples was analyzed with an ICP-OES Optima 700DV analyzer. The crystalline product was analyzed with an x-ray diffraction analyzer (XRD Xpert PRO). Scanning electron microscope (SEM-Hitachi TM-1000) images were taken of the crystalline samples. The particle size distribution of the precipitated double salt crystals was analyzed with a Malvern Mastersizer 2000® particle size analyzer. The crystalline product was washed using 25 g pure water for 10 min at a stirring rate of 360 rpm.

Results

Solubility of Sodium Lanthanum Sulfate Monohydrate in Pure Water

Higher concentrations of sodium sulfate reduce the solubilities of lanthanum sulfate and lanthanum sodium sulfate and their hydrates, as reported in Silcock’s ‘Solubilities of Inorganic and Organic Compounds’17 and by Das et al.18 As the solubility data on obtained precipitate of the monohydrate of lanthanum sodium sulfate in pure water were not available, the solid-liquid equilibrium was determined gravimetrically at three temperatures. To determine the solubility of monohydrate of sodium lanthanum double salt in water, 1 g NaLa(SO4)2⋅H2O was mixed with 50 g H2O for 24 h at three different temperatures. The solubility of the sodium lanthanum monohydrate double salt expressed as the anhydrate form in pure water at 25°C and 50°C was almost the same after the dissolution time of 24 h: 0.25 g NaLa(SO4)2/100 g H2O and 0.28 g NaLa(SO4)2/100 g H2O, respectively, whereas at 70°C, the solubility was 0.46 g NaLa (SO4)2 in 100 g H2O. We would point out here that the longer dissolution times may result in different solubility results.

Semi-Batch Precipitation by Adding Acidic Sodium Sulfate Solution

It was found that sodium lanthanum double salt precipitation occurred only at the higher temperature of 70°C when acidic Na2SO4(aq) solution was pumped into the pregnant solution. The high temperature tests and their initial concentrations are shown in Table III.

Based on the lower solubility of the pure double salt in pure water at 25°C (see supplementary Figure S1), the crystal yield was expected to be higher at lower temperature. According to the results, experiments at low temperature (25°C) did not yield any crystals, whereas precipitation with the same solutions at 70°C resulted in double salt crystals. Low temperature experiments were conducted with the similar solution composition as in high-temperature experiments, but no crystals were obtained. Thus, the impurities and solution acidity studied tend to clearly change the solubility of the lanthanum sodium sulfate double salt. Therefore, the precipitation temperature is a critical factor for crystallizing the double salt from the pregnant solution.

Purity of Crystals

It has been observed that the initial concentration of impurities has a significant effect on the final purity of the double salt crystals. The elementary analysis of the sodium lanthanum sulfate double monohydrate salt crystals is shown in Table IV. In some tests, the impurity concentrations were below the detection limit of the ICP-OES device. Each time the concentration of nickel in the solution was higher than the concentration of the other impurities; thus, a significant amount of nickel was detected in all double salt crystal samples.

Even after washing, some impurities were still detected in the crystal samples. The weight fraction of each impurity detected in the salt crystals is shown in Table IV. Based on Table IV data, the lowest total impurity concentration of crystals was 23.3 mg impurity per gram of crystal and 0.084 mg impurity/mg La (see supplementary Table SI), whereas the highest total impurity concentration in crystals of Test 8 was 291 mg impurity per gram of crystals and 2.744 mg impurity/mg La (see supplementary Table SI).

No cobalt was identified in the salt crystals of samples obtained from Tests 4 and 5. When the initial concentration of cobalt was high and the concentrations of both Fe and Zn were low, cobalt was not detected in the crystals (Test 4). In addition, cobalt was not detected when all the initial concentrations of Co, Fe, and Zn were low (Test 5). On the other hand, in Test 3, when the initial concentrations of Co and Zn were low, but the concentration of Fe was high, cobalt was detected in the double salt crystals at 2.0 g cobalt/g salt crystals (Table IV). In addition, when the initial concentrations of Co and Fe were low, but the concentration of Zn was high (Test 7), 3.2 g cobalt/g salt crystals was detected in the crystals.

Therefore, there is a direct correlation between the concentrations of Fe and Zn and the impurity level of cobalt in the double salt crystals. Regardless of the initial concentration of the cobalt and other impurities, the Co content in the crystals can only be minimized when the concentrations of both Fe and Zn are < 0.4 M in case of the studied solution compositions.

Aluminum impurity was not detected in the salt crystals in Tests 2 and 3, where the initial Al concentration was low and the Na/La molar ratio was also low (3 mol/mol). On the other hand, when the Na/La molar ratio was low, but the initial concentration of Al was high (Tests 1 and 4), Al impurity was detected in the double salt crystals (15.1 mg Al/g crystals and 5.5 mg Al/g crystals, respectively). When the initial concentration of Al was low and the Na/La molar ratio was high, at 9 mol/mol (Tests 6 and 7), Al impurity was detected in the double salt crystals at 3.3 mg Al/g crystals and 3.0 mg/g crystals, respectively. Hence, a higher Na/La molar ratio can lead to the co-precipitation of Al with sodium lanthanum double salt. Aluminum impurity can be avoided when its initial concentration is no higher than 0.2 M and the Na/La molar ratio is < 3 mol/mol.

Manganese was not detected in the salt crystals in Tests 4, 6, or 7. For instance, in Test 4, all the initial concentrations of Mn, Fe, and Zn were low, and Mn was not detected in the salt crystals. Furthermore, manganese was not detected in the salt crystals when the initial concentrations of Mn and the concentration of either Fe or Zn was low (Tests 6 and 7). In all other tests, Mn was detected in the salt crystals. Therefore, manganese will not be detected in the double salt crystals when its initial concentration and the concentration of either Fe or Zn is also low.

Iron and zinc were not detected in the salt crystals when their initial concentrations were low. However, Test 3 seems to be exceptional; although the initial concentration of Zn was low, a small amount of Zn (0.5 mg/g crystals) was still detected in the salt crystals. Therefore, impurities of both iron and zinc in double salt crystals can be avoided if their initial concentrations are < 0.4 M. In general, it seems that the concentrations of iron and zinc affect the purity of the double salt crystals. It can be concluded that Fe and Zn can be considered as critical impurities.

The purity of the double salt was calculated according to the elementary analysis by ICP-OES (Table IV). The mass of pure sodium lanthanum sulfate monohydrate double salt crystals (mDS) was divided by the total mass of the precipitated double salt crystals (\(m_{crystals}\)) (Eq. 1, Table IV). The mass of the pure double salt (mDS) was calculated from the molar amount of lanthanum, i.e., from the ICP results for La/crystals based on nDS = nLa. The precipitated double salt crystals were in monohydrate form, and the mass of water in the crystals was calculated based on its stoichiometric ratio:

The obtained results on elementary analysis and relative purification efficiencies are presented in Table IV. The highest purity of double salt monohydrate achieved was > 0.74 (Tests 4 and 6), and the lowest purity was 0.28 (Test 8). Test 4 had the highest mass fraction ratio w0/wcry value of 209, indicating the highest purification efficiency when comparing impurity (Ni, Co, Al, Mn, Fe, and Zn) and lanthanum mass fractions in the initial solution and crystals. Test 8 was the test in which the concentrations of the impurities in crystals were at the highest level (Table IV). In Test 1 concentrations of both Fe and Zn were high. In addition, in both Test 1 and Test 8, all added impurities were detected in the salt crystals; this contributed to their low levels of purification efficiency.

In Test 4, Mn, Fe, and Zn were not observed in the double salt crystals, because their initial concentrations were low. However, concentrations of both Co and Al were high, and only Al was detected in the sodium lanthanum double salt crystals. According to the ICP-OES analyses, both Test 6 and Test 4 resulted in the highest lanthanum concentration in the double salt crystals, at 279 mg/g crystals and 276 mg La/g crystals, respectively. Therefore, these two tests resulted in the highest purity compared to the other tests. Based on the obtained crystal impurity results, it was concluded that the mole fraction ratio of 3 mol Na/mol La would be favorable for double salt precipitation.

Crystal Structure, Shape, and Size

According to the x-ray diffraction results, the precipitated crystals were monohydrate sodium lanthanum double salt crystals. The XRD patterns of all the samples were similar (see supplementary Figure S1). Thus, the XRD results confirmed that all the precipitates were a monohydrate of the sodium lanthanum sulfate double salt, NaLa(SO4)2⋅H2O.

The aggregate sizes formed by single crystals are seen from the laser diffraction-based Malvern analysis results, whereas the SEM images show the shape and size of single crystals. According to the scanning electronic microscopy (SEM) images obtained, single crystals were mainly hexagonal, which is one of the common forms of crystalline sodium lanthanum sulfate monohydrate. The SEM images of double salt crystals from Tests 1, 4, 6, and 8 are shown in Fig. 2. The SEM images show that all the crystals have a similar morphology and size, except those from Test 8, illustrated in Fig. 2d, which shows that smaller single crystals were obtained. The smaller single crystal size may be one of the main reasons why Test 8 yielded the most impure crystals, as shown in Table IV.

To investigate the particle size distribution (PSD) of the double salt crystals produced, a Malvern Mastersizer 2000 laser diffraction analyzer was used. By comparing the SEM images of single crystals in Fig. 2 and Malvern results indicating larger particle sizes (see supplementary Figures S2a and S2b), it was concluded that the studied double salt tends to form aggregate precipitates. A higher aggregation tendency usually leads to more impure crystalline products due to entrapment of the mother liquor containing impurities in the internal voids of aggregate particles.

The smallest medians (D50) were observed in Tests 3, 7, and 2: 26 μm, 29 μm, and 31 μm, respectively, whereas the largest D50 sizes were observed in Tests 1 and 4, 87 μm and 63 μm, respectively. On the other hand, Tests 6, 7, and 2 had the smallest D90 values: 101 μm, 177 μm, and 254 μm, respectively. The largest D90 values were observed in Tests 4, 3, and 1: 563 μm, 348 μm, and 446 μm, respectively. Therefore, the D50 values of the double salt crystals presented in this work are > 100 μm, and the D90 value varies between 100 μm and 560 μm.

Batch Precipitation with Solid Sodium Sulfate

The reactant form of sodium sulfate in the pregnant solution, either solid or as the solute in aqueous solution, has a significant effect on the precipitation of the double salt crystals. When the Na2SO4(s) was first dissolved with 1 M H2SO4 and then pumped into the pregnant solution, this decreased the supersaturation degree in the pregnant solution compared to the direct batchwise addition of solid sodium sulfate to the pregnant solution.

Purity of Crystals

To investigate batch precipitation with the addition of solid reactant, a similar initial solution to that of Test 4 was selected as a case study; the solution composition and impurity concentrations are shown in Tables III (Test 4b, units in mass fractions) and Table V (units in mole fractions). The quantities of lanthanum and sodium obtained as well as the impurities in the crystals are depicted in Table VI (mass ratio between impurity and lanthanum, see supplementary Table SII). The precipitation at the lowest temperature of 25 °C yielded the highest lanthanum quantity in crystals and highest separation efficiency when using the elementary analysis results of lanthanum quantity and six cationic impurities for comparison between the initial solution and the crystals. At the three temperatures studied, the batchwise addition of solid sodium sulfate resulted in higher impurity levels than the semi-batch addition of acidic sodium sulfate solution at 70 °C.

According to the results, the lowest Ni concentration (26.5 mg/g crystals) and Co concentration (8.8 mg/g crystals) in the double salt crystals were obtained at 25°C and the highest (63 mg Ni/g crystals, 20.7 mg Co/g crystals) at 50°C. When the crystallization temperature was increased to 70°C, the cobalt concentration was slightly higher than in the crystals obtained at 25°C and impurities almost doubled in crystals at 50°C. Similarly, the concentrations of Al and Mn impurities in the double salt crystals were lower at 25°C and 70°C, but slightly higher at 50°C. The impurities of Fe and Zn in the double salt crystals were the same at both 25°C and 70°C and two-fold greater at 50°C. The results clearly show the influence of temperature on precipitation kinetics and purification efficiency when solid Na2SO4 is added batchwise to an acidic lanthanum sulfate solution containing impurities.

Crystal Shape and Size

The SEM images of the single double salt crystals for Test 4b are shown in Fig. 3. The laser diffraction particle size analyzer Malvern Mastersizer 2000 was used to analyze the particle size distribution of the aggregates formed by double salts. The results obtained are discussed below. The high crystallization temperature, 70°C, resulted in the smallest median D50 of 13 μm, whereas the lower crystallization temperature, 25°C, yielded a D50 of 33 μm. The crystallization at 50°C resulted in an extremely large D50, i.e., 264 μm. The D90 values of the double salt crystals were large: 556 μm at 70°C, 910 μm at 50 °C, and 221 μm at 25°C. Compared to the semi-batch addition of acidic sodium sulfate solution in Tests 1-8, the double salt crystals were larger based on the Malvern results corresponding to the aggregate sizes. The single crystals, based on the SEM images in Figs. 2b and 3c, were smaller when solid Na2SO4 was added to the pregnant solution in Test 4b.

Real-Time Monitoring of Count Rates of Different Chord Length Fractions with Two reactant Feeding Systems Studied

This section presents the obtained inline monitoring data on count rates of two chord length fractions for the semi-batch precipitation studied with acidic sodium sulfate solution and batch precipitation with solid sodium sulfate. With the aid of Particle Track, IC FBRM 4.4 (Focused Beam Reflectance Measurement), it was possible to investigate the crystallization kinetics of the sodium lanthanum monohydrate salt. Particle Track gives an in situ overview of the crystallization process, such as the starting time of nucleation and trends of different chord length fractions over time.

The FBRM real-time measurement of count rates during the formation of different chord length fractions at 70 °C is shown in Fig. 4a and b. Figure 4a shows the real-time measured count rates of various chord length fractions of the double salt crystals when the aqueous solution of Na2SO4 (aq) was pumped semi-batchwise into the pregnant solution in Test 4. No nucleation was observed during Na2SO4 (aq) solution pumping, which took 13 min. After pumping, nucleation started 1 min after the pumping ended. The count rates of the larger chord length fraction (10–100 μm) stabilized quickly and reached a constant level 15 min after solution pumping had been completed. The count rate increase of the smallest chord length fraction (< 10 μm) continued for another hour. Therefore, using acidic sodium sulfate solution involved a slow crystallization process, thus requiring longer residence time. As shown in Fig. 4a, the chord length fraction < 10 µm is dominant based on the higher count rate values.

When solid Na2SO4 was directly added batchwise to the pregnant solution in Test 4b leading to a higher supersaturation degree, nucleation started immediately, and the crystallization process reached equilibrium within 15 min, as shown in Fig. 4b. In this case, the larger chord length fraction predominated the population system based on count rates. Thus, solid Na2SO4 can result in crystallization of double salt crystals of relatively large particle size. The obtained Particle Track results were consistent with the Malvern laser diffraction results. Both analysis methods showed that the systems for adding solid reactant in Test 4b yielded larger crystals than the addition of acidic sodium sulfate solution in Test 4 at 70°C. However, based on the SEM images, single crystals were larger in precipitation with acidic sodium sulfate solution in Test 4b than in precipitation with solid sodium sulfate. These results show that the formation of secondary crystals, classified as aggregates based on SEM images, has a key role in the properties of crystalline product, especially in precipitation with solid sodium sulfate.

When solid Na2SO4 was added to the pregnant solution at 25°C and 50°C, significant amounts of double salt crystals formed, whereas no crystals were formed at these temperatures when aqueous acidic Na2SO4 solution was used. The reactant adding of solid Na2SO4 may enhance heterogeneous nucleation, which seems to make the precipitation faster. Shorter residence time is beneficial for the recovery of lanthanum from the NiMH battery leaching solutions, but on the other hand primary single crystals are smaller and the purity of crystalline product lower (see also supplementary Tables S1 and S2).

As shown in Fig. 5a, as soon as solid Na2SO4 was added to the pregnant solution, the formation of both small and large chord length fractions started to increase and continued for 1.15 min until reaching steady state. At a temperature of 25°C, the double salt crystals formed only when solid Na2SO4 was used (Fig. 5b). Before adding solid Na2SO4, all other solids had to be dissolved in the pregnant solution, so the chemical dissolution and precipitation took almost 5 h in total at 25°C. Due to the lower crystallization temperature, even after solid Na2SO4 was added to the solution, the reaction was very slow. In contrast to the higher crystallization temperatures (50°C and 70°C), it was difficult to achieve steady state in a short time. As expected, the crystallization time depends on the temperature: the higher the temperature is, the shorter the crystallization time. Moreover, the results obtained from Particle Track showed that, especially at 25°C, the precipitation of the double salt was slow. As purification efficiency by crystallization depends to a large extent on the crystal growth rate, the lower crystallization rates at 25°C may lead to higher crystal purities, as presented in Section 3.3.1. It should also be pointed out here that reactant dissolution of solid sodium sulfate particles requires a longer time at 25°C, which has an influence on the overall kinetics in the case of heterogeneous reactant systems. The Particle Track analyzer proved to be a useful tool for the comparison of precipitation conditions regarding kinetic phenomena.

Discussions and Conclusion

This study presents obtained results on the reactive crystallization of sodium lanthanum sulfate monohydrate double salt from synthetic NiMH battery leaching solution containing selected sulfate impurities (Ni, Co, Al, Mn, Fe, and Zn). The principal investigated variables were crystallization temperature and the system for adding the sodium sulfate reactant. Either acidic sodium sulfate solution was added by pumping in semi-batch mode or sodium sulfate was added batchwise as a solid powder. For controlling the purity, yield, and crystal size distribution in precipitation of sodium lanthanum sulfate monohydrate double salt from a NiMH battery leaching solution, temperature and adding method of sodium sulfate reactant are the fundamental process parameters to be considered.

When acidic sodium sulfate solution was used, the double salt was obtained at 70°C, but not at 25°C. When solid sodium sulfate was added to the pregnant solution, the double salt crystals were produced at all three studied temperatures, i.e., 25°C, 50°C, and 70°C. The precipitation process at 25°C proved to be slow, taking about 4 h. The particle size distribution analyses showed that relatively large particles were produced when solid sodium sulfate was used, whereas single crystals tended to be small. This indicates that aggregation has a major effect on the external appearance of the end-product.

The double salt purities obtained were < 80%, determined from the measured lanthanum quantity in crystals. Based on the obtained results of overall impurities and lanthanum quantity in the crystals, it was concluded that 3:1 molar ratio of sodium and lanthanum and semi-batch reactant adding of sodium sulfate solution at 70°C resulted in the lowest impurity levels and greatest lanthanum quantities in the crystals. Inline count rate measurement of two chord length fractions for real-time kinetics monitoring was successfully conducted.

References

V. Forti, C.P. Baldé, R. Kuehr, G. Bel, ”The Global E-waste Monitor 2020: Quantities, flows and the circular economy potential”, (Bonn, Geneva and Rotterdam: United Nations University/United Nations Institute for Training and Research, International Telecommunication Union, and International Solid Waste Association, 2020, 120 pp.), https://www.itu.int/en/ITU-D/Environment/Pages/Spotlight/Global-Ewaste-Monitor-2020.aspx (Accessed 19 Jul 2021).

“A New Circular Vision for Electronics: Time for a Global Reboot”, (2020). https://www.weforum.org/reports/a-new-circular-vision-for-electronics-time-for-a-global-reboot (Accessed 19 Jul 2021).

C. Tunsu, M. Petranikova, M. Gergoric, C. Ekberg, and T. Retegan, Hydrometallurgy 156, 239. https://doi.org/10.1016/j.hydromet.2015.06.007 (2015).

A. Porvali, S. Ojanen, B.P. Wilson, R. Serna-Guerrero, and M. Lundström, J. Sustain. Metall. 6, 78. https://doi.org/10.1007/s40831-019-00258-2 (2020).

P. Ruetschi, F. Meli, and J. Desilvestro, J. Power Sources. 57, 85. https://doi.org/10.1016/0378-7753(95)02248-1 (1995).

T. Muller, and B. Friedrich, J. Power Sources. 158, 1498. https://doi.org/10.1016/j.jpowsour.2005.10.046 (2006).

M. Petranikova, I. Herdzik-Koniecko, B.M. Steenari, and C. Ekberg, Hydrometallurgy 171, 128. https://doi.org/10.1016/j.hydromet.2017.05.006 (2017).

European Commission, “Study on the EU’s list of Critical Raw Materials – Final Report”, (2020). https://op.europa.eu/en/publication-detail/-/publication/c0d5292a-ee54-11ea-991b-01aa75ed71a1/language-en, doi: https://doi.org/10.2873/11619 (Accessed 19 Jul 2021).

“Rare Earths, Global Industry, Markets & Outlook 2018”, (Roskill, 2018). https://roskill.com/market-report/rare-earths/ (accessed 19 May 2019).

S. Maroufi, R.K. Nekouei, R. Hossain, M. V. Assefi Sahajwalla, ACS Sustain. Chem. Eng. 6, 11811 (2018), https://doi.org/10.1021/acssuschemeng.8b02097.

M.S. Wickleder, Chem. Rev. 102, 2011. https://doi.org/10.1021/cr010308o (2002).

L.E.O.C. Rodrigues, and M.B. Mansur, J. Power Sources. 195, 3735. https://doi.org/10.1016/j.jpowsour.2009.12.071 (2010).

A.M. Wilson, P.J. Bailey, P.A. Tasker, J.R. Turkington, R.A. Grant, and J.B. Love, Chem. Soc. Rev. 43, 123. https://doi.org/10.1039/C3CS60275C (2014).

L. Pietrelli, B. Bellomo, D. Fontana, and M.R. Montereali, Hydrometallurgy 66, 135–139. https://doi.org/10.1016/j.hydromet.2017.05.006 (2002).

K. Provazi, B.A. Campos, D.C.R. Espinosa, and J.A.S. Tenório, Waste Manage. 31, 59. https://doi.org/10.1016/j.wasman.2010.08.021 (2011).

A. Porvali, B.P. Wilson, and M. Lundström, Waste Manage. 71, 381. https://doi.org/10.1016/j.wasman.2017.10.031 (2018).

Solubilities of Inorganic and Organic Compounds, H.L. Silcock (Edit.), Vol. 3, Part 1, Pergamon Press, Oxford, UK, 1979.

G. Das, M.M. Lencka, A. Eslamimanesh, P. Wang, A. Anderko, R.E. Riman, and A. Navrotsky, J. Chem. Thermodynam. https://doi.org/10.1016/j.jct.2018.10.020 (2019).

Acknowledgements

We would like to acknowledge the School of Chemical Engineering at Aalto University for the support in financing the postdoctoral researcher position of Arshe Said, DSc (Tech.). The authors would also like to thank the BATCircle project, supported by Business Finland, grant number 4853/31/2018 of research collaboration. The work was supported by the Academy of Finland's RawMatTERS Finland Infrastructure (RAMI) at Aalto University. Furthermore, the authors gratefully acknowledge Antti Porvali, DSc (Tech), for the discussions and ideas.

Funding

Open Access funding provided by Aalto University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Said, A., Lundström, M. & Louhi-Kultanen, M. Recovery of Lanthanum from Aqueous Solutions by Crystallization as Lanthanum Sodium Sulfate Double Salt. JOM 74, 3010–3020 (2022). https://doi.org/10.1007/s11837-022-05259-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05259-3