Abstract

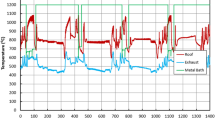

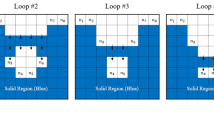

Exhaust flue gas temperature fired in aluminum industry furnaces can reach approximately 600–650 °C, with the thermal accounting for 40–50% of the total input energy. Therefore, the heat recovery of exhaust flue gas can be utilized in an adapted furnace to heat aluminum billets with the heat recovered from flue gas. This work aims to study the effectiveness of preheating billets with flue gas and assess a flawless design for a green preheating furnace. Therefore, a finite element heat treatment (FEHT) and turbulent fluid flow are coupled in a computational fluid dynamics (CFD) model to simulate billet logs in the furnace and the energy consumption and the heat treatment cycle time. The results show the persuasiveness of the novel strategy, with a decrease in energy loss and reducing the heat treatment time.

Similar content being viewed by others

References

Y. Hu, M.C.M. Bakker, and P.G. de Heij, Waste Manag. 31(12), 2422. (2011).

L.Z. Yang, T. Jiang, G.H. Li, Y.F. Guo, and F. Chen, High Temp. Mater. Process 37(4), 357. (2018).

D. Baffari, G. Buffa, G. Ingarao, A. Masnata, and L. Fratini, Procedia Manufacturing 29, 560. (2019).

M. Samuel, J. Mater. Process. Technol. 135, 117. (2003).

S.K. Padamata, A. Yasinskiy, and P. Polyakov, JOM 73, 2603. (2021).

S. Capuzzi, and G. Timelli, Metals 8, 24. (2018).

K. Vas, in Using technology and automation for enhanced returns in aluminium scrap processing. Paper presented at the 21st International Recycled Aluminium Conference, Dubai, U.A.E., 3-5 Nov 2013

Z. Luo, A. Soria, Prospective study of the world aluminium industry. EUR22951EN.2008. https://core.ac.uk/download/pdf/38614531.pdf. Accessed 19 Mar 2007

A. Steinfeld, Energy 22, 311. (1997).

L. Kuchariková, E. Tillová, and O. Bokůvka, Transp. Probl. 11, 117. (2016).

W.D. Menzie, J.J. Barry, D.I. Bleiwas, E.L. Bray, T.G. Goonan, and G. Matos, The Global Flow of Aluminum from 2006 Through 2025: U.S. Geological Survey Open-File Report 2010–1256, 73 (2010) https://pubs.usgs.gov/ofr/2010/1256/

R. Zhao, C. Nowicki, L. Gosselin, and C. Duchesne, Int. J. Energy Res. 345 (2016)

J.M. Cullen, and J.M. Allwood, Environ. Sci. Technol. 47, 1. (2013).

R.L. Milford, J.M. Allwood, and J.M. Cullen, Resour. Conserv. Recycl. 55, 1185. (2011).

H. Kvande, Inorg. Bioinorg. Chem. 1(10), 234. (2015).

G. Liu, and D.B. Müller, J. Clean Prod. 35, 108. (2012).

The Aluminium Association. Aluminium Recycling n.d. https://www.aluminum.org/industries/production/recycling. Accessed 19 Aug 2019

H. Kvande, J. Occup. Environ. Med. 56, 2. (2004).

M. Bertram, K.J. Martchek, and G. Rombach, J. Ind. Ecol. 13, 650. (2009).

S. Capuzzi, and G. Timelli, Metals 8, 24. (2008).

R. Lumley, Fundamentals of aluminium metallurgy: production, processing and applications (Woodhead Publishing Ltd., Cambridge, 2011), pp 49–57.

L. Acevedo, S. Usón, and J. Uche, Energy Conv. Manag. 89, 484. (2015).

S. Brückner, S. Liu, L. Miró, M. Radspieler, L.F. Cabeza, and E. Lävemann, Appl. Energy 151, 157. (2015).

T. Arink, and M.I. Hassan, in Metal scrap preheating using flue gas waste heat. Paper presented at the 8th International Conference on Applied Energy (ICAE2016), Beijing, China, 8-11 Oct (2016)

C. Nowicki, and L. Gosselin, JOM 64, 990. (2012).

E. Balomenos, I. Gianopoulou, D. Panias, I. Paspaliaris, A. Nikolaos and K. Perry, in Efficient and complete exploitation of the bauxite residue (Red Mud) produced in the Bayer process. Paper presented at the European Metallurgical Conference (EMC-2011), Düsseldorf, Germany, 26-29 June (2011)

Y.J. Yang, M. Hyland, Z.W. Wang, and C. Seal, Can. Metall. Q. 54, 149. (2015).

G. Lu, T. Zhang, L. Ma, Y. Wang, W. Zhang, Z. Zhang, and L. Wang, Hydrometallurgy 188, 248. (2019).

B. Zhou, Y. Yang, M.A. Reuter, and U.M.J. Boin, Miner. Eng. 19(3), 308. (2006).

N. Oumarou, D. Kocaefe, Y. Kocaefe, B. Morais, and J. Chabot, Mat. Sci. Tech. 3, 2071. (2013).

F. Grégoire, and L. Gosselin, Int. J. Therm. Sci. 129, 532. (2018).

A.R. Tajik, T. Shamim, M. Zaidani, and R.K. Abu Al-Rub, Appl. Energy 230, 207. (2018).

K. Padamata, A.S. Yasinskiy, and P.V. Polyakov, J. Sib. Fed. Univ. Chem. 11, 18. (2018).

W. Aluminium, Fluoride Emissions. http://www.world-aluminium.org/statistics/fluoride-emission/. Accessed 22 Aug 2019

M.A. Diop, X. Chen and M.I. Hassan, in Billets heat treatment using flue gas for energy efficiency and batching batching cycle time reduction. Paper presented at the 8th International Conference on Applied Energy (ICAE2016), Beijing, China, 8-11 Oct (2016)

M.A. Diop, Z. Shi, M. Fafard, S.A. Bousso, T. Wenju, and Z. Wang, J. Sustain. Metall. 7(1), 46. (2021).

Hertwich, Leading technology in the aluminium cast house: melting. https://docplayer.net/26785654-Leading-technology-in-the-aluminium-casthouse-casting.html. Accessed 02 Aug 2012

I.C. Álvarez, J. Barbero, and J.L. Zofío, J. Stat. Softw. 95(3), 1. (2020).

E.S. Menon, Transmission pipeline calculations and simulations manual (Elsevier Science, Oxford, 2015), pp 431–471.

Acknowledgements

The present work is supported by “the Fundamental Research Funds for the Central Universities” under the grant number N°2125012.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Diop, M.A., Liu, X. & Feng, S. Aluminum Billets Heat Treatment Using Hot Flue Gas in Batch Homogenizing Preheating Furnace for Energy Efficiency and Cycle Time Reduction in Cast House. JOM 74, 2770–2782 (2022). https://doi.org/10.1007/s11837-022-05228-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05228-w