Abstract

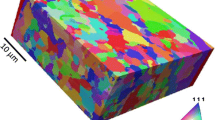

As an example of data fusion in the context of 3D characterization of materials, this article demonstrates the procedures necessary to align and fuse separate imaging modes, traditional backscattered electron imaging (BSE) and electron backscattered diffraction mapping (EBSD), from serial-sectioning data. The fused data form a unified 3D reconstruction of additively manufactured 316L stainless steel processed by laser powder-bed fusion. We show that, by combining the relatively low-information yet high-fidelity BSE image stack with the more data-rich yet spatially distorted EBSD maps, the 3D reconstruction can leverage the strengths of both imaging techniques. The fully automated alignment procedures and frameworks rely on a number of optimized image warping techniques, with the result that spatial alignment errors are on the order of 0–3 \(\upmu {\hbox {m}}\) within a region of interest that is \(> 1\) mm.

Similar content being viewed by others

References

I.M. Robertson, C.A. Schuh, J.S. Vetrano, N.D. Browning, D.P. Field, D. Juul Jensen, M.K. Miller, I. Baker, D.C. Dunand, R. Dunin-Borkowski, B. Kabius, T. Kelly, S. Lozano-Perez, A. Misra, G.S. Rohrer, A.D. Rollett, M.L. Taheri, G.B. Thompson, M.D. Uchic, X.L. Wang, and G. Was, J. Mater. Res. 26(11), 1341 (2011). https://doi.org/10.1557/jmr.2011.41

B. Khaleghi, A. Khamis, F.O. Karray, and S.N. Razavi, Inf. Fus. 14(1), 28 (2013). https://doi.org/10.1016/j.inffus.2011.08.001

T.L. Burnett, and P.J. Withers, Nat. Mater. 18(10), 1041 (2019). https://doi.org/10.1038/s41563-019-0402-8

K. Thornton, and H.F. Poulsen, MRS Bull. 33(6), 587 (2008). https://doi.org/10.1557/mrs2008.123

D.R. Clark, M. Rühle, and D.N. Seidman (eds.), Annu. Rev. Mater. Res., 42 (Annual Reviews, 2012)

D.J. Jensen, Curr. Opin. Solid State Mater. Sci. 24(4), 100862 (2020). https://doi.org/10.1016/S1359-0286(20)30060-7

R. Vincent, and P. Midgley, Ultramicroscopy 53(3), 271 (1994). https://doi.org/10.1016/0304-3991(94)90039-6

P. Moeck, S. Rouvimov, E.F. Rauch, M. Véron, H. Kirmse, I. Häusler, W. Neumann, D. Bultreys, Y. Maniette, and S. Nicolopoulos, Cryst. Res. Technol. 46(6), 589 (2011). https://doi.org/10.1002/crat.201000676

D.M. Saylor, A. Morawiec, and G.S. Rohrer, Acta Mater. 51(13), 3663 (2003). https://doi.org/10.1016/S1359-6454(03)00181-2

D.J. Rowenhorst, A. Gupta, C.R. Feng, and G. Spanos, Scripta Materialia 55(1), 11 (2006). https://doi.org/10.1016/j.scriptamat.2005.12.061

A. Lewis, J. Bingert, D. Rowenhorst, A. Gupta, A. Geltmacher, and G. Spanos, Mater. Sci. Eng. A 418(1–2), 11 (2006). https://doi.org/10.1016/j.msea.2005.09.088

A. Deal, D.J. Rowenhorst, B. Laflen, I. Spinelli, T. Barbuto, Y. Huang, and T. Hanlon, in First International Conference on 3D Materials Science, ed. by M. De Graef, H.F. Poulsen, A.C. Lewis, J.P. Simmons, G. Spanos (Seven Springs, PA, 2012), pp. 13–18. https://doi.org/10.1002/9781118686768.ch2

W. Ludwig, P. Reischig, A. King, M. Herbig, E.M. Lauridsen, G. Johnson, T.J. Marrow, and J.Y. Buffiere, Rev. Sci. Instrum. 80(3), 033905 (2009). https://doi.org/10.1063/1.3100200

A.D. Spear, S.F. Li, J.F. Lind, R.M. Suter, and A.R. Ingraffea, Acta Mater. 76, 413 (2014). https://doi.org/10.1016/j.actamat.2014.05.021

W.C. Lenthe, M.P. Echlin, A. Trenkle, M. Syha, P. Gumbsch, and T.M. Pollock, J. Appl. Crystallogr. 48(4), 1034 (2015). https://doi.org/10.1107/s1600576715009231

S.P. Donegan, and M.A. Groeber, Data Structures and Workflows for ICME (Springer, 2020), pp. 19–53. https://doi.org/10.1007/978-3-030-40562-5_2

M.P. Echlin, A. Mottura, C.J. Torbet, and T.M. Pollock, Rev. Sci. Instrum. 83(2), 023701 (2012). https://doi.org/10.1063/1.3680111

B.L. Boyce, and M.D. Uchic, MRS Bull. 44(4), 273 (2019). https://doi.org/10.1557/mrs.2019.75

M.G. Chapman, M.D. Uchic, J.M. Scott, M.N. Shah, S.P. Donegan, P.A. Shade, W.D. Musinski, M. Obstalecki, M.A. Groeber, and D. Menasche et al., Microsc. Microanal. 25(S2), 342 (2019). https://doi.org/10.1017/s1431927619002447

D.J. Rowenhorst, L. Nguyen, A.D. Murphy-Leonard, and R.W. Fonda, Curr. Opin. Solid State Mater. Sci. (2020). https://doi.org/10.1016/j.cossms.2020.100819

M.V. Kral, and G. Spanos, Acta Mater. 47, 711 (1999). https://doi.org/10.1016/S1359-6454(98)00321-8

M. Kral, M. Mangan, G. Spanos, and R. Rosenberg, Mater. Charact. 45(1), 17 (2000). https://doi.org/10.1016/s1044-5803(00)00046-2

J. Alkemper, and P.W. Voorhees, J. Microsc.-Oxford 201, 388 (2001). https://doi.org/10.1046/j.1365-2818.2001.00832.x

J. Alkemper, and P.W. Voorhees, Acta Mater. 49, 897 (2001). https://doi.org/10.1016/S1359-6454(00)00355-4

J.E. Spowart, H.M. Mullens, and B.T. Puchala, JOM 55(10), 35 (2003). https://doi.org/10.1007/s11837-003-0173-0

J.E. Spowart, Scr. Mater. 55, 5 (2006). https://doi.org/10.1016/j.scriptamat.2006.01.019

M. De Graef, M.V. Kral, and M. Hillert, JOM 58(12), 25 (2006). https://doi.org/10.1007/BF02748491

D.J. Rowenhorst, J.P. Kuang, K. Thornton, and P.W. Voorhees, Acta Mater. 54(8), 2027 (2006). https://doi.org/10.1016/j.actamat.2005.12.038

D.J. Rowenhorst, A.C. Lewis, and G. Spanos, Acta Mater. 58(16), 5511 (2010). https://doi.org/10.1016/j.actamat.2010.06.030

C. Kuglin, and D. Hines, in Proceedings of the IEEE 1975 International Conference on Cybernetics and Society (1975), pp. 163–165

S. Kim, and W. Su, in 1993 IEEE International Conference on Acoustics, Speech, and Signal Processing, vol. 5 (1993), vol. 5, pp. 153–156. https://doi.org/10.1109/ICASSP.1993.319770

C. Lafond, T. Douillard, S. Cazottes, P. Steyer, and C. Langlois, Ultramicroscopy 186, 146 (2018). https://doi.org/10.1016/j.ultramic.2017.12.019

S. Wang, JOM 59(10), 37 (2007). https://doi.org/10.1007/s11837-007-0129-x

P.T. Brewick, S.I. Wright, and D.J. Rowenhorst, Ultramicroscopy 200, 50 (2019). https://doi.org/10.1016/j.ultramic.2019.02.013

G. Nolze, Mater. Sci. Technol. 22(11), 1343 (2006). https://doi.org/10.1179/174328406x130894

G. Nolze, Ultramicroscopy 107(2–3), 172 (2007). https://doi.org/10.1016/j.ultramic.2006.07.003

M.A. Linne, and S. Daly, Mater. Charact. (2019). https://doi.org/10.1016/j.matchar.2019.109984

M.A. Groeber, B.K. Haley, M.D. Uchic, D.M. Dimiduk, and S. Ghosh, Mater. Charact. 57(4–5), 259 (2006). https://doi.org/10.1016/j.matchar.2006.01.019

S. Zaefferer, S.I. Wright, and D. Raabe, Metall. Mater. Trans. A 39(2), 374 (2008). https://doi.org/10.1007/s11661-007-9418-9

M.P. Echlin, M. Straw, S. Randolph, J. Filevich, and T.M. Pollock, Mater. Charact. 100, 1 (2015). https://doi.org/10.1016/j.matchar.2014.10.023

Y. Zhang, A. Elbrønd, and F. Lin, Mater. Charact. 96, 158 (2014). https://doi.org/10.1016/j.matchar.2014.08.003

M.A. Charpagne, F. Strub, and T.M. Pollock, Mater. Charact. 150, 184 (2019). https://doi.org/10.1016/j.matchar.2019.01.033

V.S. Tong, and T.B. Britton, Ultramicroscopy 221, 113130 (2021). https://doi.org/10.1016/j.ultramic.2020.113130

J.P.W. Pluim, J.B.A. Maintz, and M.A. Viergever, IEEE Trans. Med. Imag. 22(8), 986 (2003). https://doi.org/10.1109/TMI.2003.815867

E.B. Gulsoy, J.P. Simmons, and M. De Graef, Scr. Mater. 60(6), 381 (2009). https://doi.org/10.1016/j.scriptamat.2008.11.004

E.B. Gulsoy, Computational Tools for Analysis of Automated Three-Dimensional Microstructural Characterization Data. Ph.D. thesis, Carnegie Mellon Pittsburgh, Pennsylvania (2010)

Q. Razlighi, N. Kehtarnavaz, and S. Yousefi, J. Vis. Commun. Image Represent. 24(7), 977 (2013). https://doi.org/10.1016/j.jvcir.2013.06.010

Z. Chen, W. Lenthe, J.C. Stinville, M. Echlin, T.M. Pollock, and S. Daly, Exp. Mech. 58(9), 1407 (2018). https://doi.org/10.1007/s11340-018-0419-y

B. Winiarski, A. Gholinia, K. Mingard, M. Gee, G. Thompson, and P. Withers, Ultramicroscopy 226, 113315 (2021). https://doi.org/10.1016/j.ultramic.2021.113315

T. Britton, J. Jiang, Y. Guo, A. Vilalta-Clemente, D. Wallis, L. Hansen, A. Winkelmann,and A. Wilkinson, Mater. Charact. 117, 113 (2016). https://doi.org/10.1016/j.matchar.2016.04.008

Acknowledgements

The authors would like to gratefully acknowledge Michael Kirka at Oakridge National Laboratory for providing the sample material for this work. We also would like to acknowledge the financial support of the Office of Naval Research under the Agile ICME Toolkit project (N0001421WX00899, N0001420WX00405) and the US Naval Research Laboratory (Contract No. 63-1P95, 63-1G76).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nguyen, L.T., Rowenhorst, D.J. The Alignment and Fusion of Multimodal 3D Serial Sectioning Datasets. JOM 73, 3272–3284 (2021). https://doi.org/10.1007/s11837-021-04865-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04865-x