Abstract

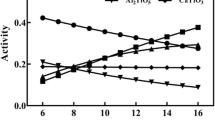

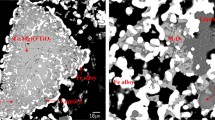

This study discusses the smelting behaviors of chromium-bearing vanadium titanomagnetite pellets (CVTP) with TiO2 additions. The results show that the softening start temperature T10% increases from 1148°C to 1215°C, and the softening end temperature T40% increases from 1280°C to 1336°C. The melting start temperature TS increases from 1318°C to 1352°C and the dripping temperature TD decreases from 1558°C to 1505°C. The primary phases of slag are (Ti0.7V0.3)2O3, (Mg0.6Ti2.4)O5, MgSiO3, and MgTi2O5, and the equilibrium phases calculated by FactSage 7.0 verify the primary phases. The titanium-vanadium compound as an intermediate reactant is generated at the interface of pig iron and slag. The FT-IR results show the depolymerization of slag, which results in the improvement of the softening–melting behaviors.

Similar content being viewed by others

References

M. Gan, Z.Y. Ji, X.H. Fan, W. Lv, R.Y. Zheng, X.L. Chen, S. Liu, and T. Jiang, Powder Technol. 333, 385. (2018).

M. Gan, Y.F. Sun, X.H. Fan, Z.Y. Ji, W. Lv, X.L. Chen, and T. Jiang, Ironmak. Steelmak. 47, 130. (2018).

T.L. Li, C.Y. Sun, D. Lan, J. Song, S. Song, and Q. Wang, ISIJ Int. 59, 245. (2019).

K. Zhou, J.Q. Song, Z.X. You, H.E. Xie, and X.W. Lv, ISIJ Int. 60, 1409. (2020).

J.L. Liao, J. Li, X.D. Wang, and Z.T. Zhang, Ironmak. Steelmak. 39, 133. (2012).

I.I. Sohn, W.L. Wang, H. Matsuura, F. Tsukihashi, and D.J. Min, ISIJ Int. 52, 158. (2012).

A. Shankar, M. Görnerup, A.K. Lahiri, and S. Seetharaman, Metall. Trans. B 38B, 911. (2007).

K. Zheng, Z.T. Zhang, L.L. Liu, and X.D. Wang, Metall. Trans. B 45B, 1389. (2014).

Y.H. Gao, L.T. Bian, and Z.Y. Liang, Steel Res. Int. 86, 386. (2015).

T.L. Li, C.Y. Sun, S. Song, and Q. Wang, Metals 9, 743. (2019).

K.X. Jiao, J.L. Zhang, Z.Y. Wang, C.L. Chen, and Y.X. Liu, Steel Res. Int. 88, 1600296. (2017).

S.T. Yang, W.D. Tang, M. Zhou, T. Jiang, X.X. Xue, and W.J. Zhang, Minerals 7, 210. (2017).

S.T. Yang, M. Zhou, W.D. Tang, T. Jiang, X.X. Xue, and W.J. Zhang, Minerals 7, 107. (2017).

M. Handke, M. Sitarz, and W. Mozgawa, J. Mol. Struct. 450, 229. (1998).

M. Sitarz, M. Handke, W. Mozgawa, E. Galuskin, and I. Galuskina, J. Mol. Struct. 555, 357. (2000).

M. Sitarz, M. Handke, and W. Mozgawa, Spectrochim. Acta Part A 56, 1819. (2000).

D.M. Zirl, and S.H. Garofalini, J. Am. Ceram. Soc. 73, 2848. (1990).

P. Tarte, Spectrochim. Acta Part A 23, 2127. (1967).

H. Kim, W.H. Kim, Il. Sohn, and D.J. Min, Steel Res Int. 81, 261. (2010).

J. Qi, C.J. Liu, and M.F. Jiang, J Non-Cryst Solids. 475, 101. (2017).

S.F. Zhang, X. Zhang, H.J. Peng, L.Y. Wen, G.B. Qiu, M.L. Hu, and C.G. Bai, ISIJ Int. 54, 734. (2014).

H. Park, J.Y. Park, G.H. Kim, and Il. Sohn, Steel Res Int. 83, 150. (2012).

Acknowledgements

The authors are especially thankful to the National Natural Science Foundation of China (Grant Nos. 51674084 and 21908020).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tang, W., Yang, S. & Xue, X. Effect of Titanium on the Smelting Process of Chromium-Bearing Vanadium Titanomagnetite Pellets. JOM 73, 1362–1370 (2021). https://doi.org/10.1007/s11837-021-04608-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04608-y