Abstract

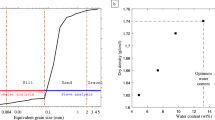

The leaching process of vanadium from the calcification-roasted vanadium slag by sodium carbonate was researched. The effect of the main parameters on the sodium carbonate leaching process was investigated, and a kinetics analysis for the process using a new shrinking core model is presented. The results indicate that the leaching rate of vanadium significantly depends on the leaching temperature. Under the conditions of 6% CaO additive content in the roasted samples, 10:1 ml g−1 liquid–solid ratio, 80 g L−1 Na2CO3, and 30 min at 90°C, the leaching rate of vanadium is 86.64%. The clean and efficient utilization of vanadium slag can be achieved by the calcification roasting and sodium carbonate leaching process. Scanning electron microscopy/energy dispersive x-ray spectroscopy analysis shows that the vanadium slag can be effectively leached by sodium carbonate with few impurities drawn into the solution. The leaching kinetics of this process shows that the interfacial transfer and diffusion across the product layer affect the leaching at the same time. Moreover, the calculated activation energy of the leaching process is 40.93 kJ/mol, and the reaction order of the sodium carbonate concentration is 0.49.

Similar content being viewed by others

References

R.R. Moskalyk and A.M. Alfantazi, Miner. Eng. 16, 793 (2003).

G.Q. Zhang, T.A. Zhang, G.Z. Lü, Y. Zhang, Y. Liu, and W.G. Zhang, JOM 68, 577 (2016).

G.Q. Zhang, T.A. Zhang, G.Z. Lü, Y. Zhang, Y. Liu, and Z.L. Liu, Int. J. Min. Met. Mater. 22, 21 (2015).

Y.M. Zhang, S.X. Bao, T. Liu, T.J. Chen, and J. Huang, Hydrometallrugy 109, 116 (2011).

L. Jia, Y.M. Zhang, T. Liu, J. Huang, and S.X. Bao, J. Clean. Prod. 22, 21 (2015).

M.Y. Wang, X.Y. Xiang, L.P. Zhang, and L.S. Xiao, Rare Met. 27, 112 (2008).

Z.H. Sun, Ironsteelvanad. Titan. 33, 1 (2012).

D.S. He, Q.M. Feng, G.F. Zhang, L.M. Ou, and Y.P. Lu, Miner. Eng. 20, 1184 (2007).

X.S. Li and B. Xie, Int. J. Miner. Metall. Mater. 19, 595 (2012).

X.S. Li, B. Xie, G.E. Wang, and X.J. Li, Trans. Nonferrous Met. Soc. China 21, 1860 (2011).

S.M.J. Mirazimi, F. Rashchi, and M. Saba, Sep. Purif. Technol. 116, 175 (2013).

S.Y. Zhao, Research on Calcified Technology of Vanadium Extraction from Vanadium Slag (Boston: Northeast. Univ., 2012), pp. 8–10.

M.Y. Wang, L.S. Xiao, Q.G. Li, X.W. Wang, and X.Y. Xiang, Rare Met. 28, 1 (2009).

H.L. Zhao, G.Q. Zhang, G.Z. Lyu, and T.A. Zhang, J. Northeastern Univ. (Nat. Sci.) 35, 1288 (2014).

P.H. Ye, X.W. Wang, M.Y. Wang, Y.Y. Fan, and X.Y. Xiang, Hydrometallurgy 2012, 108 (2012).

X.B. Zhu, Y.M. Zhang, J. Huang, T. Liu, and Y. Wang, Int. J. Miner. Process 21, 114 (2012).

Y. Zhang, T.A. Zhang, G.Z. Lv, G.Q. Zhang, Y. Liu, and W.G. Zhang, Hydrometallurgy 166, 87 (2016).

Y. Zhang, T.A. Zhang, D. Dreisinger, W.H. Zhou, F. Xie, G.Z. Lv, and W.G. Zhang, Sep. Purif. Technol. 190, 123 (2018).

Y.L. Zhao, Y.M. Zhang, T. Liu, T.J. Chen, Y. Bian, and S.X. Bao, Int. J. Miner. Process. 121, 1 (2013).

H.Y. Li, K. Wang, W.H. Hua, Z. Yang, W. Zhou, and B. Xie, Hydrometallurgy 160, 18 (2016).

Z. Yang, H.Y. Li, X.C. Yin, Z.M. Yan, X.M. Yan, and B. Xie, Int. J. Miner. Process. 133, 105 (2014).

J.H. Zhang, W. Zhang, Y.X. Yang, L. Zhang, and L. Zhang, J. Northeast. Univ.(Nat. Sci.) 35, 831 (2014).

W.C. Song, H. Li, F.X. Zhu, K. Li, and Q. Zheng, Trans. Nonferrous Met. Soc. China 24, 2687 (2014).

X.Y. Zou, Q.J. Peng, Y.Z. Ouyang, and R.G. Tian, Chin. J. Process Eng. 1, 189 (2001).

S.X. Xia, R. Lin, X. Cui, and J. Shan, Int. J. Hydrogen Energy 41, 11380 (2016).

L. Wang, T.A. Zhang, G.Z. Lv, Z.H. Dou, W.G. Zhang, J.J. Zhang, L.P. Niu, and Y. Liu, Miner. Eng. 130, 85 (2019).

G.Q. Zhang, T.A. Zhang, and G.Z. Lv, JOM 68, 577 (2015).

G.Q. Zhang, D. Luo, C. Deng, L. Lv, and B. Liang, J. Alloys Compd. 742, 504 (2018).

Y.K. Huang, Z.H. Dou, and T.A. Zhang, Hydrometallurgy 173, 15 (2017).

R.J. Ma, Principle on Hydrometallurgy (Beijing: Metallurgical Industry Press, 2007), pp. 321–352. in Chinese.

C.F. Dickinson and G.R. Heal, Thermochim. Acta 340–341, 89 (1999).

Acknowledgements

This research was financial supported by the National Natural Science Foundation of China (Nos. 51874078, U1710257, 51874094), State Key Laboratory of Pressure Hydrometallurgical Technology of Associated Nonferrous Metal Resources (YY2016006), Fundamental Research Funds for the Central Universities of China (Nos. N182505038, N140203005, N140204015), Shenyang Science and Technology Project (17-500-8-01, Z18-5-022), Science and Technology Leading Talents Training Plan (2017HA012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lu, G., Zhang, T., Zhang, G. et al. Process and Kinetic Assessment of Vanadium Extraction from Vanadium Slag Using Calcification Roasting and Sodium Carbonate Leaching. JOM 71, 4600–4607 (2019). https://doi.org/10.1007/s11837-019-03672-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03672-9