Abstract

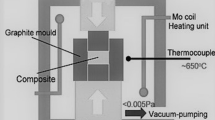

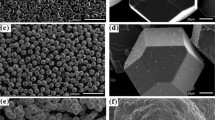

Copper/diamond composites have great potential to lead the next generation of advanced heat sink materials for use in high-power electronic devices and high-density integrated circuits because of their potential excellent properties of high thermal conductivity and close thermal expansion to the chip materials (e.g., Si, InP, GaAs). However, the poor wettability between copper and diamond presents a challenge for synthesizing copper/diamond composites with effective metallurgical bonding and satisfied thermal performance. In this article, copper/diamond composites were successfully prepared by hot forging of elemental copper and artificial diamond powders with small amounts (0 vol.%, 3 vol.% and 5 vol.%) of titanium additives. Microstructure observation and mechanical tests showed that adding minor titanium additions in the copper/diamond composite resulted in fewer cracks in the composites’ microstructure and significantly improved the bonding between the copper and diamond. The strongest bonding strength was achieved for the copper/diamond composite with 3 vol.% titanium addition, and the possible reasons were discussed.

Similar content being viewed by others

References

T. Schubert, A. Brendel, K. Schmid, T. Koeck, L. Ciupinski, W. Zielinski, T. Weissgarber, and B. Kieback, Compos. Part A Appl. Sci. Manuf. 38, 2398 (2007).

J.M. Molina, M. Rheme, J. Carron, and L. Weber, Scr. Mater. 58, 393 (2008).

R. Arpon, J.M. Molina, R.A. Saravanan, C.G. Cordovilla, E. Louis, and J. Narciso, Acta Mater. 51, 3145 (2003).

M. Schobel, H.P. Degischer, S. Vaucher, M. Hofmann, and P. Cloetens, Acta Mater. 58, 6421 (2010).

P.W. Ruch, O. Beffort, S. Kleiner, L. Weber, and P.J. Uggowitzer, Compos. Sci. Technol. 66, 2677 (2006).

J. Grzonka, M.J. Kruszewski, M. Rosiński, L. Ciupiński, A. Michalski, and K.J. Kurzydłowski, Mater. Charact. 99, 188 (2015).

K. Chu, Z.F. Liu, C.C. Jia, H. Chen, X.B. Liang, W.J. Gao, W.H. Tian, and H. Guo, J. Alloys Compd. 490, 453 (2010).

Q.L. Che, X.K. Chen, Y.Q. Ji, Y.W. Li, L.X. Wang, S.Z. Cao, Y.G. Jiang, and Z. Wang, Mater. Sci. Semicond. Process. 30, 104 (2015).

Y. Zhang, H.L. Zhang, J.H. Wu, and X.T. Wang, Scr. Mater. 65, 1097 (2011).

L. Weber and R. Tavangar, Scr. Mater. 57, 988 (2007).

W.P. Shen, W.J. Shao, Q.Y. Wang, and M.L. Ma, Fusion Eng. Des. 85, 2237 (2010).

E.A. Ekimov, N.V. Suetin, A.F. Popovich, and V.G. Ralchenko, Diam. Relat. Mater. 17, 838 (2008).

A.M. Abyzov, S.V. Kidalov, and F.M. Shakhov, Appl. Therm. Eng. 48, 72 (2012).

S.B. Ren, X.Y. Shen, C.Y. Guo, N. Liu, J.B. Zang, X.B. He, and X.H. Qu, Compos. Sci. Technol. 71, 1550 (2011).

J.L. Murray, Bull. Alloys Phase Diagr. 4, 81 (1983).

T. Schubert, B. Trindade, T. Weißgärber, and B. Kieback, Mater. Sci. Eng. A 475, 39 (2008).

S. Kleiner, F.A. Khalid, P.W. Ruch, S. Meier, and O. Beffort, Scr. Mater. 55, 291 (2006).

Y.S. Liao and S.Y. Luo, J. Mater. Sci. 28, 1245 (1993).

S. Nagarjuna, M. Srinivas, K. Balasubramanian, and D.S. Sarma, Mater. Sci. Eng. A 259, 34 (1999).

K. Chu, C.C. Jia, H. Guo, and W.S. Li, Mater. Des. 45, 36 (2013).

Acknowledgements

We gratefully acknowledged the funding from the US Air Force Asian Office of Aerospace R&D (Grant No. FA2386-17-1-4025) and the University of Waikato, New Zealand (Grant No. 2017-SIF-F759) that supported this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, F., Sun, W., Singh, A. et al. Effect of Minor Titanium Addition on Copper/Diamond Composites Prepared by Hot Forging. JOM 70, 2243–2248 (2018). https://doi.org/10.1007/s11837-018-2815-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2815-2