Abstract

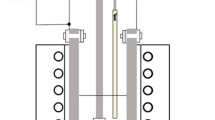

In this study, nickel-boron (Ni-B) alloys were produced via a carbothermic reduction starting from boric acid (H3BO3) with high-purity nickel oxide (NiO), charcoal, and wood chips in a direct current arc furnace. In electric arc furnace experiments, different starting mixtures were used, and their effects on the chemical compositions of the final Ni-B alloys were investigated. After the reduction and melting stages, Ni-B alloys were obtained by tapping from the bottom of the furnace. The samples from the designated areas were also taken and analyzed. The chemical composition of the final alloys and selected samples were measured with wet chemical analysis. The Ni-B alloys had a composition of up to 14.82 mass% B. The phase contents of the final alloys and selected samples were measured using x-ray diffraction (XRD). The XRD data helped predict possible reactions and reaction mechanisms. The material and energy balance calculations were made via the XRD Rietveld and chemical compositions. Nickel boride phases started to form 600 mm below the surface. The targeted NiB phase was detected at the tapping zone of the crucible (850–900 mm depth). The energy consumption was 1.84–4.29 kWh/kg, and the electrode consumption was 10–12 g/kg of raw material charged.

Similar content being viewed by others

References

J.R. Davis, ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys (Materials Park: ASM International, 2000), pp. 1–124.

R.C. Reed, The Superalloys: Fundamentals and Applications (Cambridge: Cambridge University Press, 2006), pp. 1–32.

V. Vitry, A.F. Kanta, and F. Delaunois, Surf. Coat. Technol. 206, 1879 (2011).

A.J. Frierdich, C.E. Joseph, and T.J. Strathmann, Appl. Catal. B 90, 175 (2009).

V.I. Balakai, V.V. Ivanov, I.V. Balakai, and A.V. Arzumanova, Russ. J. Appl. Chem. 82, 851 (2009).

I. Rajagopal, Bull. Mater. Sci. 5, 323 (1983).

V. Vitry, A.F. Kanta, and F. Delaunois, Mater. Des. 39, 269 (2012).

C.R. Pichard, Z. Bouhala, A.J. Tosser, A. Rashid, and J. Flechon, J. Mater. Sci. 20, 3305 (1985).

I.M. Fedorchenko, Y.A. Guslienko, and A.P. Epik, Powder Metall. Metall. Ceram. 11, 626 (1972).

F. Delaunois and P. Lienard, Surf. Coat. Technol. 160, 239 (2002).

Z.C. Wang, F. Jia, L. Yu, Z.B. Qi, Y. Tang, and G.L. Song, Surf. Coat. Technol. 206, 3676 (2012).

A. Corrias, G. Ennas, A. Musinu, G. Paschina, and D. Zedda, J. Non Cryst. Solids 192, 565 (1995).

V.I. Fadeeva, L.M. Kubalova, and I.A. Sviridov, Steel Trans. 41, 451 (2011).

J. Peng, R. He, M. Tan, Y. Dou, Z. Wang, G.Z. Chen, and X. Jin, J. Electrochem. Soc. 162, H271 (2015).

S.M. Nekhamin, A.G. Lunin, M.M. Krutyanskii, and A.K. Filippov, Refract. Ind. Ceram. 46, 37 (2005).

R.T. Jones, Celebrating the Megascale: Proceedings of the Extraction and Processing Division Symposium on Pyrometallurgy in Honor of David GC Robertson, eds. P.J. Mackey, E.J. Grimsey, R.T. Jones, and G.A. Brooks (Hoboken: Wiley, 2014), pp. 16–20.

R. Hahn, H.J. Retelsdorf, R. Fichte, and S. Sattelberger, U.S. Patent 4623386 (1986).

O. Yücel, F. Cinar, O. Addemir, and A. Tekin, High Temp. Mater. Proc. 15, 103 (1996).

C.W. Bale, et al., Calphad 33, 295 (2009).

E.J. Dickinson, H. Ekström, and E. Fontes, Electrochem. Commun. 40, 71 (2014).

J.E. Keem and J.M. Honig, Selected Electrical and Thermal Properties of Undoped Nickel Oxide (Lafayette: CINDAS, 1978), pp. 1–78.

Acknowledgements

The authors thank Sentes-BIR and ITU-BAP (Istanbul Technical University, Office of Scientific Researches Projects) for financial support of this study. The authors thank Alper Kelesoglu (Yalova University) for assistance in COMSOL modeling and Zehra Inci Kol for assistance in chemical analysis.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Alkan, M., Tasyürek, K.C., Bugdayci, M. et al. DC Electric Arc Furnace Application for Production of Nickel-Boron Master Alloys. JOM 69, 1654–1662 (2017). https://doi.org/10.1007/s11837-017-2439-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2439-y