Abstract

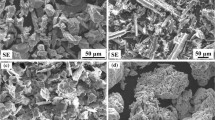

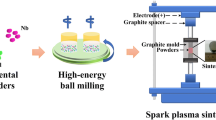

A TiC-based ceramic composite with refractory high-entropy-alloy (HEA) binders was developed through a novel reactive sintering method. In the process, refractory carbide powders were reacted with Ti powder at high temperature, and in situ formation of Ti carbides and refractory HEA phases occurred. The results indicate that only body-centered-cubic HEA phases and TiC phases are formed after the reactive sintering. The microstructure of the composite is homogeneous, consisting of ultra-fine TiC particles with an average size of 0.85 μm and HEA grains with an average grain size of 1.8 μm. The TiC/HEA composite shows an ultra-high room-temperature compressive strength (>3000 MPa), compared to 1790–2210 MPa for the conventional TiC cermets.

Similar content being viewed by others

References

V.A. Tracey, Int. J Refract. Met. Hard Mater. 11, 137 (1992).

C.S. Chen, C.C. Yang, H.Y. Chai, J.W. Yeh, and J.H. Chau, Int. J Refract. Met. Hard Mater. 43, 200 (2014).

C.M. Lin, C.W. Tsai, S.M. Huang, C.C. Yang, and J.W. Yeh, JOM 66, 2050 (2014).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

M.C. Gao, JOM 65, 1749 (2013).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Prog. Mater Sci. 61, 1 (2014).

J.W. Yeh, JOM 65, 1759 (2013).

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Intermetallics 18, 1758 (2010).

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Intermetallics 19, 698 (2011).

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miracle, and C.F. Woodward, J. Alloy. Compd. 509, 6043 (2011).

O.N. Senkov and C.F. Woodward, Mater. Sci. Eng. 529A, 311 (2011).

C. Jerry, W.L. Meyer, and A.M. Meyers, J. Am. Ceram. Soc. 131, 592 (1992).

A. Teber, F. Schoenstein, F. Têtard, M. Abdellaoui, and N. Jouini, Int. J Refract. Met. Hard Mater. 30, 64 (2012).

A. Teber, F. Schoenstein, F. Têtard, M. Abdellaoui, and N. Jouini, Int. J Refract. Met. Hard Mater. 31, 132 (2012).

F.M. Binnewies and F.E. Milke, Thermochemical Data of Elements and Compounds (New York: Wiley, 2002).

S. Guo, C. Ng, J. Lu, and C.T. Liu, J. Appl. Phys. 109, 103505-5 (2011).

O.N. Senkov, S.V. Senkov, D.B. Miracle, and C. Woodward, Mater. Sci. Eng. 565A, 51 (2013).

Z.W. Wang, I. Baker, Z.H. Cai, S. Chen, J.D. Poplawsky, and W. Guo, Acta Mater. 120, 228 (2016).

Acknowledgements

The authors acknowledge the financial support from the National Natural Science Foundation of China (51671217), the Project of Innovation-driven Plan of Central South University (2015CX004) and State Key Lab of Powder Metallurgy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, B., Wang, J., Chen, J. et al. Ultra-High Strength TiC/Refractory High-Entropy-Alloy Composite Prepared by Powder Metallurgy. JOM 69, 651–656 (2017). https://doi.org/10.1007/s11837-017-2267-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2267-0