Abstract

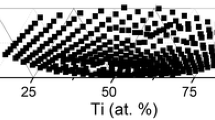

In this study, functionally graded NiTi multilayer thin films were created by radio frequency magnetrun sputtering and subsequent annealing. The chemical compositions of the multilayer thin films which determined by energy-dispersive x-ray spectroscopy are about Ni51Ti/Ni49Ti (numbers indicate at.%). The structures, surface morphology, and transformation temperatures of annealed thin films at 500°C for 1 h were studied using grazing incidence x-ray diffraction, atomic force microscopy, and differential scanning calorimetry (DSC), respectively. Moreover, a coupled nanoindentation/atomic force microscopy technique is employed to characterize both the superelastic and shape memory effects. Specifically, an analysis of recoverable energy through the stress-induced phase transformation and recoverable strain through de-twinning and the subsequent thermally induced phase transformation were performed. The DSC and x-ray diffraction results indicated the multilayer was composed of austenitic and martensitic thin films. The continuous stiffness measurement technique showed that the stiffness and elastic modulus of the multilayer change gradually through the thickness of the multilayer thin films. Also, the thin films exhibited a combined pseudoelastic behavior and shape-memory effect which produces a two-way shape-memory effect in both thin films.

Similar content being viewed by others

References

L. Delaey, R.V. Krishnan, and H. Tas, J. Mater. Sci. 9, 1521 (1974).

S. Miyazaki, K. Otsuka, and C.M. Wayman, Acta Metall. 37, 1885 (1989).

Y. Liu and P.G. McCormick, Acta Metal. Mater. 38, 1321 (1990).

Y. Fu, W. Huang, H. Du, X. Huang, J. Tan, and X. Gao, Surf. Coat. Technol. 145, 107 (2001).

T. Shahrabi, S. Sanjabi, E. Saebnoori, and Z.H. Barber, Mater. Lett. 62, 2791 (2008).

I. Shiota and Y. Miyamoto, Functionally Graded Materials (Burlington, VT: Elsevier Science, 1997).

B.A.S. Shariat and M.R. Eslami, Int. J. Solids Struct. 43, 4082 (2006).

B.A.S. Shariat and M.R. Eslami, Compos. Struct. 78, 433 (2007).

B.A.S. Shariat, R. Javaheri, and M.R. Eslami, Thin Wall Struct. 43, 1020 (2005).

L. Sun, W.M. Huang, Z. Ding, Y. Zhao, C.C. Wang, and H. Purnawali, Mater. Des. 33, 577 (2012).

S. Miyazaki, Y.Q. Fu, and W.M. Huang, Thin Film Shape Memory Alloys: Fundamentals and Device Applications, ed. S. Miyazaki, Y.Q. Fu, and W.M. Huang (Cambridge, UK: Cambridge University Press, 2009), p. 48.

B. Winzek, S. Schmitz, H. Rumpf, T. Sterzl, R. Hassdorf, and S. Thienhaus, Mater. Sci. Eng. A 378, 40 (2004).

Q. Meng, H. Yang, Y. Liu, and T. Nam, Scripta Mater. 67, 305 (2012).

Y. Fu, H. Du, W. Huang, S. Zhang, and M. Hu, Sensor. Actuat. A: Phys. 112, 395 (2004).

D.P. Cole, H.A. Bruck, and A.L. Roytburd, Strain 45, 232 (2009).

R.M.S. Martins, N. Schell, H. Reuther, L. Pereira, K.K. Mahesh, and R.J.C. Silva, Thin Solid Films 519, 122 (2010).

A. Ishida, M. Sato, Z.Y. Gao, and J. Alloys, Compd. 577, S184 (2013).

L. Tan and W.C. Crone, Acta Mater. 50, 4449 (2002).

Y. Fu, H. Du, and S. Zhang, Mater. Lett. 57, 2995 (2003).

Y. Fu, H. Du, and S. Zhang, Surf. Coat. Technol. 167, 129 (2003).

D.E. Burkes, J.J. Moore, and J. Alloys, Compd. 430, 274 (2007).

H.C. Lingand and R. Kaplow, Metall. Trans. A 11, 77 (1980).

L. Chang and D.S. Grummon, Phil. Mag. A 76, 191 (1997).

K.S.S. Eswar Raju, S. Bysakh, M.A. Sumesh, S.V. Kamat, and S. Mohan, Mater. Sci. Eng. A 476, 267 (2008).

L. Qian, M. Li, Z. Zhou, H. Yang, and X. Shi, Surf. Coat. Technol. 195, 264 (2005).

K.L. Johnson, Contact Mechanics (Cambridge, U.K.: Cambridge University Press, 1994).

G. Shaw, D.S. Stone, A.D. Johnson, A.B. Ellis, and W.C. Crone, Appl. Phys. Lett. 83, 257 (2003).

A. Ishida, A. Takei, M. Sato, and S. Miyazaki, Thin Solid Films 281, 337 (1996).

A. Ishida, M. Sato, T. Kimura, and S. Miyazaki, Philos. Mag. A 80, 967 (2000).

K. Ho and G. Carman, Thin Solid Films 370, 18 (2000).

W. Oliver and G. Pharr, J. Mater. Res. 7, 1564 (1992).

X. Li and B. Bhushan, Scripta Mater. 42, 929 (2000).

X. Li and B. Bhushan, Mater. Charact. 48, 11 (2002).

Acknowledgements

The author gratefully acknowledges Prof. Horst Hahn at the Institute of Nanotechnology (INT), Karlsruhe Institute of Technology (KIT), for providing sample preparation and characterization facilities. The authors also acknowledge the partial financial support of this work by the Iranian National Science foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohri, M., Nili-Ahmadabadi, M. Functionally Graded Shape-Memory and Pseudoelastic Response in Ni-Rich/Ti-Rich and Vice Versa NiTi Multilayer Thin Films Deposited on Si(111). JOM 67, 1585–1593 (2015). https://doi.org/10.1007/s11837-015-1339-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1339-2