Abstract

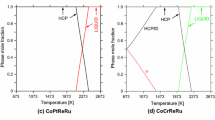

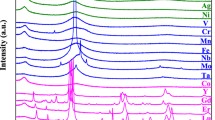

High-entropy alloys (HEAs) with an atomic arrangement of a hexagonal close-packed (hcp) structure were found in YGdTbDyLu and GdTbDyTmLu alloys as a nearly single hcp phase. The equi-atomic alloy design for HEAs assisted by binary phase diagrams started with selecting constituent elements with the hcp structure at room temperature by permitting allotropic transformation at a high temperature. The binary phase diagrams comprising the elements thus selected were carefully examined for the characteristics of miscibility in both liquid and solid phases as well as in both solids due to allotropic transformation. The miscibility in interest was considerably narrow enough to prevent segregation from taking place during casting around the equi-atomic composition. The alloy design eventually gave candidates of quinary equi-atomic alloys comprising heavy lanthanides principally. The XRD analysis revealed that YGdTbDyLu and GdTbDyTmLu alloys thus designed are formed into the hcp structure in a nearly single phase. It was found that these YGdTbDyLu and GdTbDyTmLu HEAs with an hcp structure have delta parameter (δ) values of 1.4 and 1.6, respectively, and mixing enthalpy (ΔH mix) = 0 kJ/mol for both alloys. These alloys were consistently plotted in zone S for disordered HEAs in a δ-ΔH mix diagram reported by Zhang et al. (Adv Eng Mater 10:534, 2008). The value of valence electron concentration of the alloys was evaluated to be 3 as the first report for HEAs with an hcp structure. The finding of HEAs with the hcp structure is significant in that HEAs have been extended to covering all three simple metallic crystalline structures ultimately followed by the body- and face-centered cubic (bcc and fcc) phases and to all four simple solid solutions that contain the glassy phase from high-entropy bulk metallic glasses.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

J.W. Yeh, Ann. Chim. Sci. Mater. 31, 633 (2006).

L. Ma, L. Wang, T. Zhang, and A. Inoue, Mater. Trans. 43, 277 (2002).

K. Zhao, X.X. Xia, H.Y. Bai, D.Q. Zhao, and W.H. Wang, Appl. Phys. Lett. 98, 141913 (2011).

A. Takeuchi, N. Chen, T. Wada, Y. Yokoyama, H. Kato, A. Inoue, and J.W. Yeh, Intermetallics 19, 1546 (2011).

H.Y. Ding and K.F. Yao, J. Non-Cryst. Solids 364, 9 (2013).

Y.L. Chen, C.W. Tsai, C.C. Juan, M.H. Chuang, J.W. Yeh, T.S. Chin, and S.K. Chen, J. Alloy. Compd. 506, 210 (2010).

M. Gao and D.E. Alman, Entropy 15, 4504 (2013).

E.M. Savitskii, M.A. Tylkina, and V.P. Polyakova, Russ. J. Inorg. Chem. 8, 74 (1963).

J.O.A. Paschoal, H. Kleykamp, and F. Thummler, Z. Metall. 74, 652 (1983).

T.T. Shun, C.H. Hung, and C.F. Lee, J. Alloy. Compd. 493, 105 (2010).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Prog. Mater Sci. 61, 1 (2014).

X. Yang and Y. Zhang, Mater. Chem. Phys. 132, 233 (2012).

A. Inoue and A. Takeuchi, Acta Mater. 59, 2243 (2011).

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Adv. Eng. Mater. 10, 534 (2008).

S. Guo, C. Ng, J. Lu, and C.T. Liu, J. Appl. Phys. 109, 103505 (2011).

S. Nagasaki and M. Hirabayashi, Binary Alloy Phase Diagrams (Tokyo, Japan: Agune Technical Center, Co. Ltd., 2004).

Binary Alloy Phase Diagrams: Plus Updates, 1.0 edn, 2005, ASM International (CDR Version).

A. Takeuchi and A. Inoue, Mater. Trans. 46, 2817 (2005).

Metal Databook, 604; 2004, Tokyo, Maruzen Co. Ltd.

H. Okamoto, Phase Diagrams for Binary Alloys (Materials Park, OH: ASM International, 2010).

Crystal Structures of Intermetallic Compounds (West Sussex, U.K. Wiley 2000).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Mater. Sci. Eng. A 375, 213 (2004).

Pearson’s Crystal Data, Crystal Structure Database for Inorganic Compounds (Materials Park, OH: ASM International, 2011).

Lutetium Metal 99%–99.99%, Rare Earth Limited, [viewed May 21, 2014; Available from: http://www.metall.com.cn/lum.htm.

Y. Zhang and Y. Zhou, Mater. Sci. Forum 561–565, 1337 (2007).

Acknowledgements

This work was supported by Grants-in-Aid for Scientific Research (B) from the Japan Society for the Promotion of Science (JSPS) with a program title of “Fabrication of High-Entropy Bulk Metallic Glasses based on Confusion Principle, Clarification of their Properties and their Application” (grant number 24360284).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Takeuchi, A., Amiya, K., Wada, T. et al. High-Entropy Alloys with a Hexagonal Close-Packed Structure Designed by Equi-Atomic Alloy Strategy and Binary Phase Diagrams. JOM 66, 1984–1992 (2014). https://doi.org/10.1007/s11837-014-1085-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1085-x