Abstract

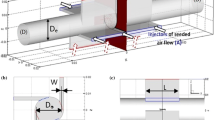

In the current work, three-dimensional mathematical models were developed for the heat transfer and combustion in a W-shape radiant tube burner (RTB) and were solved using Fluent software (ANSYS Inc., Canonsburg, PA). The standard k–ε model, nonpremixed combustion model, and the discrete ordinate model were used for the modeling of turbulence, combustion, and radiant heat transfer, respectively. In addition, the NO x postprocessor was used for the prediction of the NO emission. A corresponding experiment was performed for the validation of mathematical models. The details of fluid flow, heat transfer, and combustion in the RTB were investigated. Moreover, the effect of the air/fuel ratio (A/F) and air staging on the performance of RTB was studied with the reference indexes including heat efficiency, maximum temperature difference on shell wall, and NO emission at the outlet. The results indicated that a low speed zone formed in the vicinity of the combustion chamber outlet, and there were two relative high-temperature zones in the RTB, one in combustion chamber that favored the flame stability and the other from the main flame in the RTB. The maximum temperature difference was 95.48 K. As the A/F increased, the temperature increased first and then decreased. As the ratio of the primary to secondary air increased, the recirculation zone at the outlet of combustion chamber shrank gradually to disappear, and the flame length was longer and the temperature in flame decreased correspondingly.

Similar content being viewed by others

Abbreviations

- A/F:

-

Air/fuel ratio

- a :

-

Absorption coefficient

- Cμ, C1, C2, σ k , σ ε :

-

Constants for k–ε equations

- C g , C d , σ t :

-

Constants for nonpremixed model

- c p :

-

Thermal capacity (J/kg K)

- D :

-

Diameter of combustion chamber outlet (mm)

- D NO :

-

Molecular diffusivity of NO

- d :

-

Diameter of holes on combustion chamber (mm)

- f :

-

Mixture fraction

- G :

-

Turbulence production term

- g i :

-

Gravity components (m/s2)

- H :

-

Enthalpy (J/mol)

- I :

-

Radiation intensity (W/m2)

- k :

-

Turbulent kinetic energy (m2/s2)

- k t :

-

Thermal conductivity (W/m.K)

- M w,NO :

-

Molecular weight of NO (kg/mol)

- n :

-

Refractive index

- P :

-

Pressure (Pa)

- ppm:

-

Parts per million of mass fraction

- p(f) :

-

Probability density function

- R :

-

Universal gas constant (8.314 J/mol K)

- \( \overrightarrow {{\mathbf{r}}} \) :

-

Position vector

- S rad :

-

Source term of radiative heat transfer

- S NO :

-

NO reaction source term

- s :

-

Path length

- \( \overrightarrow {{\mathbf{s}}} \) :

-

Direction vector

- \( \overrightarrow {{\mathbf{s}}}^{{\mathbf{'}}} \) :

-

Scattering direction vector

- T :

-

Temperature (K)

- u i , u j :

-

Velocity components (m/s)

- \( X_{{{\text{O}}_{ 2} }} \) :

-

Oxygen mole fraction

- x i ,x j :

-

Spatial coordinates (m)

- Y :

-

Mass fraction

- Z :

-

Elemental mass fraction

- α, β :

-

Parameters for beta probability density function

- δ ij :

-

Kronecker symbol

- ε :

-

Turbulent dissipation rate (m2/s3)

- μ :

-

Dynamic viscosity (kg/m s)

- μ t :

-

Turbulent viscosity (kg/m s)

- ρ :

-

Density (kg/m3)

- σ :

-

Stefan-Boltzmann constant (5.669 × 10−8W/m2 K4)

- σ s :

-

Scattering coefficient

- τ ij :

-

Stress tensor (N/m2)

- Φ :

-

Phase function

- φ :

-

General variable

- ψ :

-

Equivalence ratio

- Ω ′ :

-

Solid angle

References

J. Baukal and E. Charles, Industrial Combustion Testing (Boca Raton, FL: CRC Press, 2011).

G. Scribano, G. Solero, and A. Coghe, Exp. Therm. Fluid Sci. 30, 605 (2006).

L.G. Blevins and J.P. Gore, Combust. Sci. Technol. 109, 255 (1995).

C. Chuenchit and S. Jugjai, J. Res. Appl. Mech. Eng. 1, 19 (2012).

H. Ramamurthy, S. Ramadhyani, and R. Viskanta, J. Inst. Energy 67, 90 (1994).

R.F. Harder, R. Viskanta, and S. Ramadhyani, Proc. ASME Nat. Heat Trans. Conf. 1, 67 (1988).

A. Lankhorst and F.M. Velthuis, Transp. Phenom. Combust. 2, 1330 (1995).

F. Mei and H. Meunier, ASME Publ. HTD 341, 109 (1997).

N. Tsioumanis, J.G. Brammer, and J. Hubert, Fuel 87, 103 (2008).

N. Tsioumanis, J.G. Brammer, and J. Hubert, Energ. Convers. Manage. 52, 2667 (2011).

M.D. Ahanj, M. Rahimi, and A.A. Alsairafi, Int. Commun. Heat Mass Trans. 39, 432 (2012).

H.K. Versteeg and W. Malalasekera, An Introduction to Computational Fluid Dynamics: The Finite Volume Method (Upper Saddle River, NJ: Pearson Education, 2007).

B.E. Launder and D.B. Spalding, Lectures in Mathematical Models of Turbulence (New York: Academic, 1972).

Y.B. Zeldovich, Acta Physic. URSS 21, 577 (1946).

R.K. Hanson and S. Salimian, Survey of Rate Constants in the N/H/O System, Combustion Chemistry, ed. W.C. Gardiner (New York: Springer, 1984).

G.G. De Soete, Symp. (Int.) Combust. 15, 1093 (1975).

Acknowledgements

The authors are grateful for support from the National Science Foundation China (Grant Nos. 51274034, 51334002, and U1360201), Beijing Key Laboratory of Green Recycling and Extraction of Metals (GREM), the Laboratory of Green Process Metallurgy and Modeling (GPM2), and the High Quality steel Consortium (HQSC) at the School of Metallurgical and Ecological Engineering at University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Li, J., Zhang, L. et al. Numerical Simulation of the Thermal Process in a W-Shape Radiant Tube Burner. JOM 66, 1253–1264 (2014). https://doi.org/10.1007/s11837-014-1021-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1021-0