Abstract

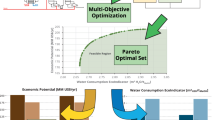

This work addresses the modeling and multi-objective optimization of methanol synthesis to efficiently utilize CO2 from the CO2 emissions and economics perspectives. Kinetic reactors for reforming and methanol synthesis reactions were used in the process simulator for modeling the entire process, and multi-objective optimization was conducted using the developed process model to maximize CO2 reduction and the economic profit. The feed composition, operating temperature and pressure of the reformer, and utility temperature of the methanol synthesis reactor were considered as arguments in the non-dominated sorting genetic algorithm (NSGA II) method with the net change of CO2 and economic profit as the objective elements, and the Pareto front showed a trade-off between CO2 reduction and economic profit. When the amount of CH4 in the feed was fixed at 500 kmol/h, CO2 reduction was 11,588 kg/h, whereas the profit was −5.79 million dollars per year. Meanwhile, a maximum profit of 20 million dollars per year resulted in CO2 emissions of 7,201 kg/h. The feed composition had the most significant influence on both objective elements (net change of CO2 and economics); as CO2 in the feed increased, CO2 reduction increased and profit decreased, while the increase of H2O in the feed increased CO2 emissions and profit.

Similar content being viewed by others

References

F. D. Meylan, V. Moreau and S. Erkman, J. CO2 Utilization, 12, 101 (2015).

A. Otto, T. Grube, S. Schiebahn and D. Stolten, Energy Environ. Sci., 8, 3283 (2015).

J. Ma, N. Sun, X. Zhang, N. Zhao, F. Xiao, W. Wei and Y. Sun, Catal. Today, 148, 221 (2009).

T. Schaub and R. A. Paciello, Angew. Chem. Int. Ed. Engl., 50, 7278 (2011).

X. Xiang, L. Guo, X. Wu, X. Ma and Y. Xia, Environ. Chem. Lett., 10, 295 (2012).

P. Nikolaidis and A. Poullikkas, Renew. Sust. Energy Rev., 67, 597 (2017).

C.-H. Huang and C.-S. Tan, Aerosol Air Quality Res., 14, 480 (2014).

N. Park, M.-J. Park, S.-C. Baek, K.-S. Ha, Y.-J. Lee, G. Kwak, H.-G. Park and K.-W. Jun, Fuel, 115, 357 (2014).

G. H. Graaf, E. J. Stamhuis and A. A. C. M. Beenackers, Chem. Eng. Sci., 43, 3185 (1988).

N. Park, M.-J. Park, K.-S. Ha, Y.-J. Lee and K.-W. Jun, Fuel, 129, 163 (2014).

C. Zhang, K.-W. Jun, R. Gao, G. Kwak and H.-G. Park, Fuel, 190, 303 (2017).

A. Alizadeh, N. Mostoufi and F. Jalali-Farahani, Int. J. Chem. React. Eng., 5, A19 (2007).

K. Atsonios, K. D. Panopoulos and E. Kakaras, Int. J. Hydrogen Energy, 41, 2202 (2016).

É. S. Van-Dal and C. Bouallou, J. Cleaner Production, 57, 38 (2013).

R. K. Sinnott, Chemical engineering design, Second edition. edn. Pergamon, Oxford (1993).

S. M. Walas, Chemical process equipment: Selection and design, Elsevier Science & Technology Books, Place of Publication Not Identified (1988).

Commodity Markets. https://www.worldbank.org/en/research/com-modity-markets.

J. M. Douglas, Conceptual design of chemical processes, International edn. McGraw-Hill, New York, London (1988).

Home — Methanol Market Services Asia. https://wwwmethanolmsa.com.

M. S. Peters, Plant design and economics for chemical engineers, McGraw-Hill, New York (1958).

W. D. Seider, J. D. Seader and D. R. Lewin, Product and process design principles: Synthesis, analysis and evaluation, Rev. of: Process design principles, 1999, Wiley, New York (2004).

Homepage — U.S. Energy Information Administration (EIA). https://www.eia.gov.

CAMEO Chemicals ∣ NOAA. https://cameochemicals.noaa.gov.

K. Deb, A. Pratap, S. Agarwal and T. Meyarivan, Ieee T Evolut Comput, 6, 182 (2002).

C. Bao, L. Xu, E. D. Goodman and L. Cao, J. Comput. Sci., 23, 31 (2017).

GitHub — edgarsmdn/Aspen_HYSYS_Python: Aspen HYSYS — Python connection. https://github.com/edgarsmdn/Aspen_HYSYS_Python.

J. Blank and K. Deb, IEEE Access, 8, 89497 (2020).

Acknowledgement

This research was supported by the Technology Innovation Program (20015460) funded by the Ministry of Trade, Industry & Energy (MOTIE, South Korea).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Supporting Information

Additional information as noted in the text. This information is available via the Internet at http://www.springer.com/chemistry/journal/11814.

Supporting Information

Rights and permissions

About this article

Cite this article

Jeong, J.H., Kim, S., Park, MJ. et al. Multi-objective optimization of a methanol synthesis process: CO2 emission vs. economics. Korean J. Chem. Eng. 39, 1709–1716 (2022). https://doi.org/10.1007/s11814-022-1134-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-022-1134-z