Abstract

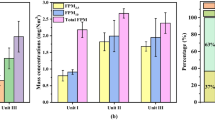

Industrial coal-fired boiler is an important air pollutant emission source in China. The chain-grate boiler is the most extensively used type of industrial coal-fired boiler. An electrical low-pressure impactor, and a Dekati® Low Pressure Impactor were applied to determine mass and number size distributions of PM10 at the inlet and the outlet of the particulate emission control devices at six coalfired chain-grate boilers. The mass size distribution of PM10 generated from coal-fired chain-grate boilers generally displays a bimodal distribution that contains a submicron mode and a coarse mode. The PM in the submicron mode for burning with raw coal contributes to 33% ± 10 % of PM10 emissions, much higher than those for pulverized boilers. And the PM in the submicron mode for burning with briquette contributes up to 86 % of PM10 emissions. Multiclones and scrubbers are not efficient for controlling PM10 emission. Their average collection efficiencies for sub-micron particle and super-micron particle are 34% and 78%, respectively. Operating conditions of industrial steam boilers have influence on PM generation. Peak of the submicron mode during normal operation period is larger than the start-up period.

Similar content being viewed by others

References

Ministry of Environmental Protection. China. Available online at http://www.zhb.gov.cn/gkml/hbb/bgth/201308/t20130805_256939. htm. (accessed 12th Dec. 12, 2015)

Neville M, Quann R J, Haynes B S, Sarofim A F. Vaporization and condensation of mineral matter during pulverized coal combustion. Proceedings of the Combustion Institute, 1981, 18 (1): 1267–1274

Quann R J, Neville M, Janghorbani M, Mims C A, Sarofim A F. Mineral matter and trace-element vaporization in a laboratorypulverized coal combustion system. Environmental Science & Technology, 1982, 16(11): 776–781

McElroy M W, Carr R C, Ensor D S, Markowski G R. Size distribution of fine particles from coal combustion. Science, 1982, 215(4528): 13–19

Moisio M. Real time size distribution measurement of combustion aerosols. Dissertation for the Doctoral Degree. Tampere: Tampere University of Technology, 1999

Yi H, Hao J, Duan L, Li X, Guo X. Characteristics of inhalable particulate matter concentration and size distribution from power plants in China. Journal of the Air & Waste Management Association, 2006, 56(9): 1243–1251

Sui J, Xu M, Du Y, Liu Y, Yu D, Yi G. Emission characteristics and chemical composition of PM10 from two coal fired power plants in China. Journal of the Energy Institute, 2007, 80(4): 192–198

Seames W S. An initial study of the fine fragmentation fly ash particle mode generated during pulverized coal combustion. Fuel Processing Technology, 2003, 81(2): 109–125

Linak W P, Miller C A, Seames W S, Wendt J O L, Ishinomori T, Endo Y, Miyamae S. On trimodal particle size distributions in fly ash from pulverized-coal combustion. Proceedings of the Combustion Institute, 2002, 29(1): 441–447

Yu D, Xu M, Yao H, Sui J, Liu X, Yu Y, Cao Q. Use of elemental size distributions in identifying particle formation modes. Proceedings of the Combustion Institute, 2007, 31(2): 1921–1928

Zhao Z, Du Q, Zhao G, Gao J, Dong H, Cao Y, Han Q, Yuan P, Su L. Fine particle emission from an industrial coal-fired circulating fluidized-bed boiler equipped with a fabric filter in China. Energy & Fuels, 2014, 28(7): 4769–4780

Turn S R. An Introduction to Combustion: Concepts and Applications. 2nd ed. Boston: McGraw-Hill, 2000

Zhang Y, Schauer J J, Zhang Y, Zeng L, Wei Y, Liu Y, Shao M. Characteristics of particulate carbon emissions from real-world Chinese coal combustion. Environmental Science & Technology, 2008, 42(14): 5068–5073

Ge S, Bai Z, Liu W, Zhu T, Wang T, Qing S, Zhang J. Boiler briquette coal versus raw coal: Part I—Stack gas emissions. Journal of the Air & Waste Management Association, 2001, 51(4): 524–533

China Pollution Source Census. Available online at http://cpsc.mep. gov.cn/ (accessed Dec. 12, 2015)

Keskinen J, Pietarinen K, Lehtimäki M J. Electrical low pressure impactor. Journal of Aerosol Science, 1992, 23(4): 353–360

Dekati Ltd Technical Note.Unidealities in ELPITM mass measurement.

Dekati@ DI-1000 diluter brochure. Available online at http://www.dekati.com/products/Aerosol%20Sample%20Conditioning/Dekati%C2%AE%20Diluter (accessed Dec. 12, 2015)

DLPI brochure. Available online at http://www.dekati.com/products/ Fine%20Particle%20Measurement/DLPI. (accessed Dec. 12, 2015)

State Environmental Protection Administration of China. Handbook of Pollutant Generation and Emission Factors from Industrial Sources. Beijing: China Environmental Science Press, 1996

Licht W. Air Pollution Control Engineering: Basic Calculations for Particulate Collection, 2nd ed. New York: Marcel Dekker,1988

Kim H T, Jung C H, Oh S N, Lee K W. Particle removal efficiency of gravitational wet scrubber considering diffusion, interception, and impaction. Environmental Engineering Science, 2001, 18(2): 125–136

Dirgo J, Leith D. Cyclone collection efficiency: comparison of experimental results with theoretical predictions. Aerosol Science and Technology, 1985, 4(4): 401–415

Zhao B. Development of a new method for evaluating cyclone efficiency. Chemical Engineering and Processing, 2005, 44(4): 447–451

Lee B K, Mohan B R, Byeon S H, Lim K S, Hong E P. Evaluating the performance of a turbulent wet scrubber for scrubbing particulate matter. Journal of the Air & Waste Management Association, 2013, 63(5): 499–506

Liu X, Xu M, Yao H, Yu D, Gao X, Cao Q, Cai Y. Effect of combustion parameters on the emission and chemical composition of particulate matter during coal combustion. Energy & Fuels, 2007, 21(1): 157–162

Acknowledgments

This study was supported by the National Natural Science Foundation of China (Grant Nos. 41275121 and 41575119) and the National Key Basic Research and Development Program of China (No. 2013CB228505) and Beijing Municipal Science & Technology Commission (Grant No. Z161100000716004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X., Han, J. & Duan, L. PM10 emissions from industrial coal-fired chain-grate boilers. Front. Environ. Sci. Eng. 11, 18 (2017). https://doi.org/10.1007/s11783-017-0966-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11783-017-0966-y