Abstract

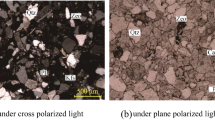

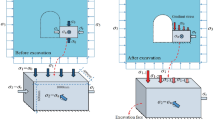

The complexity of a rock masses structure can lead to high uncertainties and risk during underground engineering construction. Laboratory tests on fractured rock-like materials containing a tunnel were conducted, and two-dimensional particle flow models were established. The principal stress and principal strain distributions surrounding the four-arc-shaped and inverted U-shaped tunnels were investigated, respectively. Numerical results indicated that the dip angle combination of preexisting fractures directly affects the principal stress, principal strain distribution and the failure characteristics around the tunnel. The larger the absolute value of the preexisting fracture inclination angle, the higher the crushing degree of compression splitting near the hance and the larger the V-shaped failure zone. With a decrease in the absolute value of the preexisting fracture inclination angle, the compressive stress concentration of the sidewall with preexisting fractures gradually increases. The types of cracks initiated around the four-arc-shaped tunnel and the inverted U-shape tunnel are different. When the fractures are almost vertical, they have a significant influence on the stress of the sidewall force of the four-arc-shaped tunnel. When the fractures are almost horizontal, they have a significant influence on the stress of the sidewall of the inverted U-shaped tunnel. The findings provide a theoretical support for the local strengthening design of the tunnel supporting structure.

摘要

岩体结构的复杂性会导致地下工程在施工过程中的高度不确定性和风险。本研究采用类岩材料室内试验和二维颗粒流数值模拟相结合的方式,分别研究了四心圆形隧道和马蹄形隧道周围的主应力和主应变分布。数值结果表明,既有的裂隙倾角组合直接影响隧道周围的主应力、主应变分布和破坏特征。预裂隙的倾角绝对值越大,两类隧洞均在拱腰(M-4 和M-5)附近的挤压劈裂破碎程度逐渐加剧,“V”形破坏区也越大。随着预裂隙倾角绝对值的减小(60°→45°→30°),预裂隙的侧壁压应力集中程度逐渐增加。四心圆形隧道和马蹄形隧道周围产生的裂缝类型不同。当裂隙近于垂直时,对四心圆形隧洞侧壁受力影响较大;而当裂隙近于水平时,对马蹄形隧洞边墙受力影响较大。以上发现,为隧道支护结构的局部加固设计提供了理论支持。

Similar content being viewed by others

References

BOBET A. The initiation of secondary cracks in compression [J]. Engineering Fracture Mechanics, 2000, 66(2): 187–219. DOI: https://doi.org/10.1016/S0013-7944(00)00009-6.

GERMANOVICH L N, SALGANIK R L, DYSKIN A V, et al. Mechanisms of brittle fracture of rock with pre-existing cracks in compression [J]. Pure and Applied Geophysics, 1994, 143(1–3): 117–149. DOI: https://doi.org/10.1007/BF00874326.

LUO Yong, GONG Feng-qiang, LIU Dong-qiao, et al. Experimental simulation analysis of the process and failure characteristics of spalling in D-shaped tunnels under true-triaxial loading conditions [J]. Tunnelling and Underground Space Technology, 2019, 90: 42–61. DOI: https://doi.org/10.1016/j.tust.2019.04.020.

YU Jin, LIU Geng-yun, CAI Yan-yan, et al. Time-dependent deformation mechanism for swelling soft-rock tunnels in coal mines and its mathematical deduction [J]. International Journal of Geomechanics, 2020, 20(3): 04019186. DOI: https://doi.org/10.1061/(asce)gm.1943-5622.0001594.

BAUD P, REUSCHLÉ T, CHARLEZ P. An improved wing crack model for the deformation and failure of rock in compression [J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1996, 33(5): 539–542. DOI: https://doi.org/10.1016/0148-9062(96)00004-6.

GOLSHANI A, OKUI Y, ODA M, et al. A micromechanical model for brittle failure of rock and its relation to crack growth observed in triaxial compression tests of granite [J]. Mechanics of Materials, 2006, 38(4): 287–303. DOI: https://doi.org/10.1016/j.mechmat.2005.07.003.

QIAN Xi-kun, LIANG Zheng-zhao, LIAO Zhi-yi, et al. Numerical investigation of dynamic fracture in rock specimens containing a pre-existing surface flaw with different dip angles [J]. Engineering Fracture Mechanics, 2020, 223: 106675. DOI: https://doi.org/10.1016/j.engfracmech.2019.106675.

WONG L N Y, EINSTEIN H H. Crack coalescence in molded gypsum and Carrara marble: Part 2—Microscopic observations and interpretation [J]. Rock Mechanics and Rock Engineering, 2009, 42(3): 513–545. DOI: https://doi.org/10.1007/s00603-008-0003-3.

WONG L N Y, LI Huan-qiang. Numerical study on coalescence of two pre-existing coplanar flaws in rock [J]. International Journal of Solids and Structures, 2013, 50(22–23): 3685–3706. DOI: https://doi.org/10.1016/j.ijsolstr.2013.07.010.

YU Jin, YAO Wei, DUAN Kang, et al. Experimental study and discrete element method modeling of compression and permeability behaviors of weakly anisotropic sandstones [J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 134: 104437. DOI: https://doi.org/10.1016/j.ijrmms.2020.104437.

CHEN Xin, LIAO Zhi-hong, PENG Xi. Cracking process of rock mass models under uniaxial compression [J]. Journal of Central South University, 2013, 20(6): 1661–1678. DOI: https://doi.org/10.1007/s11771-013-1660-2.

CHIU C C, WANG T T, WENG M C, et al. Modeling the anisotropic behavior of jointed rock mass using a modified smooth-joint model [J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 62: 14–22. DOI: https://doi.org/10.1016/j.ijrmms.2013.03.011

FAN Xiang, KULATILAKE P H S W, CHEN Xin, et al. Crack initiation stress and strain of jointed rock containing multi-cracks under uniaxial compressive loading: A particle flow code approach [J]. Journal of Central South University, 2015, 22(2): 638–645. DOI: https://doi.org/10.1007/s11771-015-2565-z.

FAN Xiang, KULATILAKE P H S W, CHEN Xin. Mechanical behavior of rock-like jointed blocks with multi-non-persistent joints under uniaxial loading: A particle mechanics approach [J]. Engineering Geology, 2015, 190: 17–32. DOI: https://doi.org/10.1016/j.enggeo.2015.02.008.

SATO A, HIRAKAWA Y, SUGAWARA K. Mixed mode crack propagation of homogenized cracks by the two-dimensional DDM analysis [J]. Construction and Building Materials, 2001, 15(5–6): 247–261. DOI: https://doi.org/10.1016/S09500618(00)00074-X.

WEI Ming-dong, DAI Feng, ZHOU Jia-wen, et al. A further improved maximum tangential stress criterion for assessing mode I fracture of rocks considering non-singular stress terms of the williams expansion [J]. Rock Mechanics and Rock Engineering, 2018, 51(11): 3471–3488. DOI: https://doi.org/10.1007/s00603-018-1524-z.

YAN Ze-lin, DAI Feng, LIU Yi, et al. Experimental and numerical investigation on the mechanical properties and progressive failure mechanism of intermittent multi-jointed rock models under uniaxial compression [J]. Arabian Journal of Geosciences, 2019, 12(22): 1–24. DOI: https://doi.org/10.1007/s12517-019-4737-x.

CHANG Xu, DENG Yan, LI Zhen-hua, et al. Crack propagation from a filled flaw in rocks considering the infill influences [J]. Journal of Applied Geophysics, 2018, 152: 137–149. DOI: https://doi.org/10.1016/j.jappgeo.2018.03.018.

ZHUANG Xiao-ying, CHUN Jun-wei, ZHU He-hua. A comparative study on unfilled and filled crack propagation for rock-like brittle material [J]. Theoretical and Applied Fracture Mechanics, 2014, 72: 110–120. DOI: https://doi.org/10.1016/j.tafmec.2014.04.004.

CARTER B J, LAJTAI E Z, YUAN Yan-guang. Tensile fracture from circular cavities loaded in compression [J]. International Journal of Fracture, 1992, 57(3): 221–236. DOI: https://doi.org/10.1007/BF00035074.

CARTER B J. Size and stress gradient effects on fracture around cavities [J]. Rock Mechanics and Rock Engineering, 1992, 25(3): 167–186. DOI: https://doi.org/10.1007/BF01019710.

GONG Feng-qiang, LUO Yong, LI Xi-bing, et al. Experimental simulation investigation on rockburst induced by spalling failure in deep circular tunnels [J]. Tunnelling and Underground Space Technology, 2018, 81: 413–427. DOI: https://doi.org/10.1016/j.tust.2018.07.035.

YANG Xu-xu, JING Hong-wen, CHEN Kun-fu, et al. Failure behavior around a circular opening in a rock mass with non-persistent joints: A parallel-bond stress corrosion approach [J]. Journal of Central South University, 2017, 24(10): 2406–2420. DOI: https://doi.org/10.1007/s11771-017-3652-0.

ZHOU X P, BAO X R, YU M H, et al. Triaxial stress state of cylindrical openings for rocks modeled by elastoplasticity and strength criterion [J]. Theoretical and Applied Fracture Mechanics, 2010, 53(1): 65–73. DOI: https://doi.org/10.1016/j.tafmec.2009.12.006.

ZHU W C, BRUHNS O T. Simulating excavation damaged zone around a circular opening under hydromechanical conditions [J]. International Journal of Rock Mechanics and Mining Sciences, 2008, 45(5): 815–830. DOI: https://doi.org/10.1016/j.ijrmms.2007.09.007.

GAY N C. Fracture growth around openings in thick-walled cylinders of rock subjected to hydrostatic compression [J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1973, 10(3): 209–233. DOI: https://doi.org/10.1016/0148-9062(73)90032-6.

CAI M, KAISER P K, TASAKA Y, et al. Determination of residual strength parameters of jointed rock masses using the GSI system [J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(2): 247–265. DOI: https://doi.org/10.1016/j.ijrmms.2006.07.005.

ZHONG Zhi-bin, DENG Rong-gui, LV Lei, et al. Fracture mechanism of naturally cracked rock around an inverted U-shaped opening in a biaxial compression test [J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 103: 242–253. DOI: https://doi.org/10.1016/j.ijrmms.2018.01.047.

YANG Sheng-qi, TIAN Wen-ling, HUANG Yan-hua, et al. Experimental and discrete element modeling on cracking behavior of sandstone containing a single oval flaw under uniaxial compression [J]. Engineering Fracture Mechanics, 2018, 194: 154–174. DOI: https://doi.org/10.1016/j.engfracmech.2018.03.003.

ZHU Wei-shen, LI Yong, LI Shu-cai, et al. Quasi-three-dimensional physical model tests on a cavern complex under high in situ stresses [J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 48(2): 199–209. DOI: https://doi.org/10.1016/j.ijrmms.2010.11.008.

WANG Wen-cai, WANG Zheng, ZHANG An, et al. Simulation study on propagation law of double-hole permeability improvement cracks with joints [J]. Safety in Coal Mines, 2019, 50(9): 21–24. DOI: https://doi.org/10.13347/j.cnki.mkaq.2019.09.007. (in Chinese)

DU Ming-rui, JING Hong-wen, SU Hai-jian, et al. Strength and failure characteristics of sandstone containing two circular holes filled with two types of inclusions under uniaxial compression [J]. Journal of Central South University, 2017, 24(11): 2487–2495. DOI: https://doi.org/10.1007/s11771-017-3661-z.

CAO Ri-hong, CAO Ping, LIN Hang, et al. Mechanical behavior of an opening in a jointed rock-like specimen under uniaxial loading: Experimental studies and particle mechanics approach [J]. Archives of Civil and Mechanical Engineering, 2018, 18(1): 198–214. DOI: https://doi.org/10.1016/j.acme.2017.06.010.

CHEN Hao, FAN Xiang, LAI Hong-peng, et al. Experimental and numerical study of granite blocks containing two side flaws and a tunnel-shaped opening [J]. Theoretical and Applied Fracture Mechanics, 2019, 104: 102394. DOI: https://doi.org/10.1016/j.tafmec.2019.102394.

FAN Xiang, CHEN Rui, LIN Hang, et al. Cracking and failure in rock specimen containing combined flaw and hole under uniaxial compression [J]. Advances in Civil Engineering, 2018, 2018: 9818250. DOI: https://doi.org/10.1155/2018/9818250.

FAN Xiang, LI Kai-hui, LAI Hong-peng, et al. Internal stress distribution and cracking around flaws and openings of rock block under uniaxial compression: A particle mechanics approach [J]. Computers and Geotechnics, 2018, 102: 28–38. DOI: https://doi.org/10.1016/j.compgeo.2018.06.002.

WANG Yi-xian, ZHANG Hui, LIN Hang, et al. Fracture behaviour of central-flawed rock plate under uniaxial compression [J]. Theoretical and Applied Fracture Mechanics, 2020, 106: 102503. DOI: https://doi.org/10.1016/j.tafmec.2020.102503.

FAN Xiang, JIANG Xu-dong, LIU Yi-xin, et al. Local stress distribution and evolution surrounding flaw and opening within rock block under uniaxial compression [J]. Theoretical and Applied Fracture Mechanics, 2021, 112: 102914. DOI: https://doi.org/10.1016/j.tafmec.2021.102914.

FAN Xiang, YANG Zhi-jun, LI Kai-hui. Effects of the lining structure on mechanical and fracturing behaviors of four-arc shaped tunnels in a jointed rock mass under uniaxial compression [J]. Theoretical and Applied Fracture Mechanics, 2021, 112: 102887. DOI: https://doi.org/10.1016/j.tafmec.2020.102887.

ZHANG Chun-yang, PU Cheng-zhi, CAO Ri-hong, et al. The stability and roof-support optimization of roadways passing through unfavorable geological bodies using advanced detection and monitoring methods, among others, in the Sanmenxia Bauxite Mine in China’s Henan Province [J]. Bulletin of Engineering Geology and the Environment, 2019, 78(7): 5087–5099. DOI: https://doi.org/10.1007/s10064-018-01439-1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(41807241) supported by the National Natural Science Foundation of China; Project(2021M693544) supported by China Postdoctoral Science Foundation; Project(2022JM-160) supported by the Natural Science Basic Research Program of Shaanxi, China

Contributors

FAN Xiang provided the concept and wrote the first draft of the manuscript. YANG Zhi-jun analyzed the measured data and edited the draft of manuscript. HONG Ming conducted the literature review and wrote the first draft of manuscript. YU Hao verified the data. XIE Yong-li provided support for the manuscript. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

FAN Xiang, YANG Zhi-jun, HONG Ming, YU Hao and XIE Yong-li declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Fan, X., Yang, Zj., Hong, M. et al. Mechanism of stress distribution and failure around two different shapes of openings within fractured rock-like materials. J. Cent. South Univ. 29, 1916–1932 (2022). https://doi.org/10.1007/s11771-022-5048-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-5048-z