Abstract

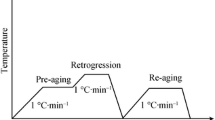

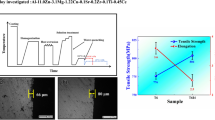

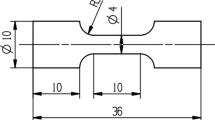

A study was conducted to better understand how different parameters, namely, regression aging time and regression aging temperature, affect the creep aging properties, i.e., the creep deformation and performance of Al-Zn-Mg-Cu alloy during regressive reaging. The corresponding creep strain and mechanical properties of samples were studied by conducting creep tests and uniaxial tensile tests. The electrical conductivity was measured using an eddy-current conductivity meter. The microstructures were observed by transmission electron microscopy (TEM). With the increase in regression aging time, the steady creep strain first increased and then decreased, and reached the maximum at 45 min. The steady creep strain increased with the increase in regression aging temperature, and reached the maximum at 200 °C. The level of steady creep strain was determined by precipitation and dislocation recovery. Creep aging strengthens 7B50-RRA treated with regression aging time at 190 °C for 10 min, and the difference in the mechanical properties of alloy becomes smaller. The diffusion of solute atoms reduces the scattering of electrons, leading to a significant improvement in electrical conductivity and stress corrosion cracking (SCC) resistance after creep aging. The findings of this study could help in the application of creep aging forming (CAF) technology in Al-Zn-Mg-Cu alloy under RRA treatment.

摘要

研究了回归时效时间和回归时效温度对Al-Zn-Mg-Cu RRA合金蠕变变形和性能的影响. 通过蠕变试验和单轴拉伸试验研究试样的蠕变应变和力学性能. 采用涡流电导率仪测定样品的电导率, 采用透射电镜(TEM)观察微组织. 结果表明, 随着回归时效时间的延长, 蠕变应变先增大后减小, 在45 min时达到最大值. 蠕变应变随回归时效温度的升高而增大, 在200 °C时达到最大. 稳态蠕变应变水平由析出相和位错回复决定. 蠕变时效强化了经190 °C回归时效10 min 的7B50-RRA合金, 减小了合金力学性能差异. 溶质原子的扩散减少了电子的散射, 使蠕变时效大大增强了材料的导电性和抗应力腐蚀性能. 研究结果有助于蠕变时效成形(CAF)技术在Al-Zn-Mg-Cu RRA合金中的应用.

Similar content being viewed by others

References

HEINZ A, HASZLER A, KEIDEL C, et al. Recent development in aluminium alloys for aerospace applications [J]. Materials Science and Engineering A, 2000, 280(1): 102–107. DOI: https://doi.org/10.1016/S0921-5093(99)00674-7.

ROUT P K, GHOSH M M, GHOSH K S. Microstructural, mechanical and electrochemical behaviour of a 7017 Al−Zn−Mg alloy of different tempers [J]. Materials Characterization, 2015, 104: 49–60. DOI: https://doi.org/10.1016/j.matchar.2015.03.025.

CHEN Cun-guang, HAN Wei-hao, QI Miao, et al. Microstructural evolution and mechanical properties of an ultrahigh-strength Al−Zn−Mg−Cu alloy via powder metallurgy and hot extrusion [J]. Journal of Central South University, 2021, 28(4): 1195–1205. DOI: https://doi.org/10.1007/s11771-021-4669-y.

SUN Wen-wen, ZHU Yu-man, MARCEAU R, et al. Precipitation strengthening of aluminum alloys by room-temperature cyclic plasticity [J]. Science, 2019, 363(6430): 972–975. DOI: https://doi.org/10.1126/science.aav7086.

AZARNIYA A, TAHERI A K, TAHERI K K. Recent advances in ageing of 7xxx series aluminum alloys: A physical metallurgy perspective [J]. Journal of Alloys and Compounds, 2019, 781: 945–983. DOI: https://doi.org/10.1016/j.jallcom.2018.11.286.

OLIVEIRA A F, DE BARROS M C, CARDOSO K R, et al. The effect of RRA on the strength and SCC resistance on AA7050 and AA7150 aluminium alloys [J]. Materials Science and Engineering A, 2004, 379(1, 2): 321–326. DOI: https://doi.org/10.1016/j.msea.2004.02.052.

XU Yong-qian, ZHAN Li-hua, LI Shu-jian, et al. Effect of stress-aging treatments on precipitates of pre-retrogressed Al−Zn−Mg−Cu alloy [J]. Rare Metal Materials and Engineering, 2017, 46(2): 355–362. DOI: https://doi.org/10.1016/S1875-5372(17)30094-2.

XU Ling-zhi, ZHAN Li-hua, XU Yong-qian, et al. Thermomechanical pretreatment of Al−Zn−Mg−Cu alloy to improve formability and performance during creep-age forming [J]. Journal of Materials Processing Technology, 2021, 293: 117089. DOI: https://doi.org/10.1016/j.jmatprotec.2021.117089.

LIN Yong-cheng, ZHANG Jin-long, LIU Guan, et al. Effects of pre-treatments on aging precipitates and corrosion resistance of a creep-aged Al−Zn−Mg−Cu alloy [J]. Materials & Design, 2015, 83: 866–875. DOI: https://doi.org/10.1016/j.matdes.2015.06.029.

LEI Chao, YANG He, LI Heng, et al. Dependence of creep age formability on initial temper of an Al−Zn−Mg−Cu alloy [J]. Chinese Journal of Aeronautics, 2016, 29(5): 1445–1454. DOI: https://doi.org/10.1016/j.cja.2016.04.022.

LIN Yong-cheng, ZHANG Jin-long, CHEN Ming-song. Evolution of precipitates during two-stage stress-aging of an Al−Zn−Mg−Cu alloy [J]. Journal of Alloys and Compounds, 2016, 684: 177–187. DOI: https://doi.org/10.1016/j.jallcom.2016.05.161.

LIN Yong-cheng, LIU Guan, CHEN Ming-song, et al. Effects of two-stage creep-aging processing on mechanical properties of an Al−Cu−Mg alloy [J]. Materials & Design, 2015, 79: 127–135. DOI: https://doi.org/10.1016/j.matdes.2015.04.047.

RATCHEV P, VERLINDEN B, de SMET P, et al. Effect of cooling rate and predeformation on the precipitation hardening of an Al−4.2wt.%Mg−0.6wt.%Cu alloy [J]. Scripta Materialia, 1998, 38(8): 1195–1201. DOI: https://doi.org/10.1016/S1359-6462(98)00024-4.

LI Hui-zhong, LIU Ruo-mei, LIANG Xiao-peng, et al. Effect of pre-deformation on microstructures and mechanical properties of high purity Al−Cu−Mg alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(6): 1482–1490. DOI: https://doi.org/10.1016/S1003-6326(16)64253-X.

GABLE B M, ZHU A W, CSONTOS A A, et al. The role of plastic deformation on the competitive microstructural evolution and mechanical properties of a novel Al−Li−Cu−X alloy [J]. Journal of Light Metals, 2001, 1(1): 1–14. DOI: https://doi.org/10.1016/S1471-5317(00)00002-X.

RODGERS B I, PRANGNELL P B. Quantification of the influence of increased pre-stretching on microstructure-strength relationships in the Al−Cu−Li alloy AA2195 [J]. Acta Materialia, 2016, 108: 55–67. DOI: https://doi.org/10.1016/j.actamat.2016.02.017.

LIN Yong-cheng, JIANG Yu-qiang, CHEN Xiao-min, et al. Effect of creep-aging on precipitates of 7075 aluminum alloy [J]. Materials Science and Engineering A, 2013, 588: 347–356. DOI: https://doi.org/10.1016/j.msea.2013.09.045.

LYU Feng-gong, LI Yong, SHI Zhu-sheng, et al. Stress and temperature dependence of stress relaxation ageing behaviour of an Al−Zn−Mg alloy [J]. Materials Science and Engineering A, 2020, 773: 138859. DOI: https://doi.org/10.1016/j.msea.2019.138859.

GUO Wei, GUO Ji-yan, WANG Jin-duo, et al. Evolution of precipitate microstructure during stress aging of an Al−Zn−Mg−Cu alloy [J]. Materials Science and Engineering A, 2015, 634: 167–175. DOI: https://doi.org/10.1016/j.msea.2015.03.047.

ZHENG Jing-hua, PAN Ran, LI Chen, et al. Experimental investigation of multi-step stress-relaxation-ageing of 7050 aluminium alloy for different pre-strained conditions [J]. Materials Science and Engineering A, 2018, 710: 111–120. DOI: https://doi.org/10.1016/j.msea.2017.10.066.

HE Zhun-ke, LI Qun, LIU Sheng-dan, et al. Influence of pre-stretching on quench sensitive effect of high-strength Al−Zn−Mg−Cu−Zr alloy sheet [J]. Journal of Central South University, 2021, 28(9): 2660–2669. DOI: https://doi.org/10.1007/s11771-021-4800-0.

LI J F, BIRBILIS N, LI C X, et al. Influence of retrogression temperature and time on the mechanical properties and exfoliation corrosion behavior of aluminium alloy AA7150 [J]. Materials Characterization, 2009, 60(11): 1334–1341. DOI: https://doi.org/10.1016/j.matchar.2009.06.007.

ZHAO Huan, GAULT B, PONGE D, et al. Reversion and re-aging of a peak aged Al−Zn−Mg−Cu alloy [J]. Scripta Materialia, 2020, 188: 269–273. DOI: https://doi.org/10.1016/j.scriptamat.2020.07.049.

NANDANA M S, BHAT K U, MANJUNATHA C M. Influence of retrogression and re-ageing heat treatment on the fatigue crack growth behavior of 7010 aluminum alloy [J]. Procedia Structural Integrity, 2019, 14: 314–321. DOI: https://doi.org/10.1016/j.prostr.2019.05.039.

XIA Peng, LIU Zhi-yi, BAI Song, et al. Enhanced fatigue crack propagation resistance in a superhigh strength Al−Zn−Mg−Cu alloy by modifying RRA treatment [J]. Materials Characterization, 2016, 118: 438–445. DOI: https://doi.org/10.1016/j.matchar.2016.06.023.

XU Yong-qian, ZHAN Li-hua, XU Ling-zhi, et al. Experimental research on creep aging behavior of Al−Cu−Mg alloy with tensile and compressive stresses [J]. Materials Science and Engineering A, 2017, 682: 54–62. DOI: https://doi.org/10.1016/j.msea.2016.11.043.

CHEN J F, JIANG J T, ZHEN L, et al. Stress relaxation behavior of an Al−Zn−Mg−Cu alloy in simulated age-forming process [J]. Journal of Materials Processing Technology, 2014, 214(4): 775–783. DOI: https://doi.org/10.1016/j.jmatprotec.2013.08.017.

CHEN Xue-ying, ZHAN Li-hua, MA Zi-yao, et al. Study on tensile/compressive asymmetry in creep ageing behavior of Al−Cu alloy under different stress levels [J]. Journal of Alloys and Compounds, 2020, 843: 156157. DOI: https://doi.org/10.1016/j.jallcom.2020.156157.

PHAM M S, IADICOLA M, CREUZIGER A, et al. Thermally-activated constitutive model including dislocation interactions, aging and recovery for strain path dependence of solid solution strengthened alloys: Application to AA5754-O [J]. International Journal of Plasticity, 2015, 75: 226–243. DOI: https://doi.org/10.1016/j.ijplas.2014.09.010.

SEIDMAN D N, MARQUIS E A, DUNAND D C. Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys [J]. Acta Materialia, 2002, 50(16): 4021–4035. DOI: https://doi.org/10.1016/S1359-6454(02)00201-X.

LUMLEY R N, MORTON A J, POLMEAR I J. Enhanced creep performance in an Al−Cu−Mg−Ag alloy through underageing [J]. Acta Materialia, 2002, 50(14): 3597–3608. DOI: https://doi.org/10.1016/S1359-6454(02)00164-7.

FENG Chun, LIU Zhi-yi, NING Ai-lin, et al. Retrogression and re-aging treatment of Al−9.99%Zn−1.72Retrogression and re-aging treatment of Al−9.99%Zn−1.72 5%Mg−0.13%Zr aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(5): 1163–1170. DOI: https://doi.org/10.1016/s1003-6326(06)60395-6.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item: Project(2017YFB0306300) supported by the National key R&D Program of China; Projects(51675538, 51905551) supported by the National Natural Science Foundation of China; Project(ZZYJKT2019-11) supported by Free Exploration Project of State Key Laboratory of High performance Complex Manufacturing, China

Rights and permissions

About this article

Cite this article

Peng, Nh., Zhan, Lh., Ma, Bl. et al. Creep aging behavior and performance of Al-Zn-Mg-Cu alloys under different parameters in retrogression aging treatment. J. Cent. South Univ. 29, 986–998 (2022). https://doi.org/10.1007/s11771-022-4955-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4955-3