Abstract

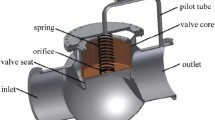

Cavitation is a destructive phenomenon in control valves. In order to delay cavitation, a multi-series of perforated cylindrical plates, called trims, are used. Previously, the effects of orifice diameter and different types of trims have been investigated. In this study, by numerical analysis, a globe control valve was investigated by employing four different cases (without trim, with one trim, with two and three trims) and the impact of the number of these trims on the intensity, formation region and the initiation point of cavitation was analyzed. It was found that the addition of one stage or two stages of trims reduces the intensity and delays the onset of cavitation, relative to the valve without trim. However, no significant differences in terms of intensity and initiation point of cavitation were observed in the cases where two or three trims were used. Therefore, due to the high cost of producing the trims, and the severe drop in flow coefficient, it is not economically and technically justified to increase the number of trims to more than three.

摘要

空化是控制阀中的一种破坏性现象。为了延缓空化, 采用一种多孔圆柱板, 称为trim。在此之 前, 我们曾研究过孔板直径和不同类型的trim 的影响。本文采用4 种不同工况(无trim, 1, 2 和3 trims) 对球阀进行数值分析, 分析了trim 的数量对气蚀强度、形成区域和空化起始点的影响。结果表明, 与 不加trim 的阀门相比, 增加一个或两个trim 可以降低气蚀的强度, 延缓空化的发生。然而, 在使用 两到三个trims 的情况下, 空化的强度和起始点没有明显的差异。由于trim 生产成本高, 流量系数严 重下降, 将trim 数量增加到3 个以上在经济和技术上都是不合理的。

Similar content being viewed by others

References

SHEN W, ZHANG J, SUN Y, ZHANG D J, JIANG J H. Effect of cavitation bubble collapse on hydraulic oil temperature [J]. Journal of Central South University, 2016, 23(7): 1657–1668. DOI: 10.1007/s11771-016-3220-z.

CASADA D. Throttled valve cavitation and erosion. ORNL/NRC/LTR-91/25 [R]. 1991.

YUZAWA S, OKUTSU R, HASHIZUME T, OUTA E. Cavitation erosion features in industrial control valves at an inlet pressure of 20 MPa [J]. JSME International Journal Series B Fluids and Thermal Engineering, 1998, 41(4): 1105–1113. DOI: 10.1299/jsmeb.41.1105.

DAVIS J A, STEWART M. Predicting globe control valve performance—Part I: CFD modeling [J]. Journal of Fluids Engineering, 2002, 124(3): 772–777. DOI: 10.1115/1.1490108.

CHERN M J, WANG C C. Control of volumetric flow-rate of ball valve using V-port [J]. Journal of Fluids Engineering, 2004, 126(3): 471–481. DOI: 10.1115/1.1760536.

MAYNES D, HOLT G, BLOTTER J. Cavitation inception and head loss due to liquid flow through perforated plates of varying thickness [J]. Journal of Fluids Engineering, 2013, 135(3): 031302. DOI: 10.1115/1.4023407.

AMIRANTE R, CATALANO L A, POLONI C, TAMBURRANO P. Fluid-dynamic design optimization of hydraulic proportional directional valves [J]. Engineering Optimization, 2014, 46(10): 1295–1314. DOI: 10.1080/0305215X.2013.836638.

ČDINA M. Detection of cavitation phenomenon in a centrifugal pump using audible sound [J]. Mechanical Systems and Signal Processing, 2003, 17(6): 1335–1347. DOI: 10.1006/mssp.2002.1514.

MARTIN C S, MEDLARZ H, WIGGERT D C, BRENNEN C. Cavitation inception in spool valves [J]. Journal of Fluids Engineering, 1981, 103: 564–575. DOI: 10.1115/1.3241768.

GAO Hong, FU Xin, YANG Hua, TSUKIJI T. Numerical investigation of cavitating flow behind the cone of a poppet valve in water hydraulic system [J]. Journal of Zhejiang University: Science B, 2002, 3(4): 395–400. DOI: 10.1007/BF02839479.

AN Y J, KIM B J, SHIN B R. Numerical analysis of 3-D flow through LNG marine control valves for their advanced design [J]. Journal of Mechanical Science and Technology, 2008, 22(10): 1998–2005. DOI: 10.1007/s12206-008-0745–6.

RAMMOHAN S, SASEENDRAN S, KUMARASWAMY S. Effect of multi jets on cavitation performance of globe valves [J]. Journal of Fluid Science and Technology, 2009, 4: 128–137. DOI: 10.1299/jfst.4.128.

MU D, LI C. A new mathematical model of twin flapper-nozzle servo valve based on input-output linearization approach [C]//Artificial Intelligence, Management Science and Electronic Commerce (AIMSEC), 2011 2nd International Conference on. IEEE, 2011: 3662–3666. DOI: 10.1109/AIMSEC.2011.6009893.

CHERN M J, HSU P H, CHENG Y J, TSENG P H, HU C M. Numerical study on cavitation occurrence in globe valve [J]. Journal of Energy Engineering, 2012, 139(1): 25–34. DOI: 10.1061/(ASCE)EY.1943-7897.0000084.

JIN Z J, WEI L, CHEN L L, QIAN J Y, ZHANG M. Numerical simulation and structure improvement of double throttling in a high parameter pressure reducing valve [J]. Journal of Zhejiang University: Science A, 2013, 14(2): 137–146. DOI: 10.1631/jzus.A1200146.

AMIRANTE R, DISTASO E, TAMBURRANO P. Experimental and numerical analysis of cavitation in hydraulic proportional directional valves [J]. Energy Conversion and Management, 2014, 87: 208–219. DOI: 10.1016/j.enconman.2014.07.031.

AUNG N Z, LI S. A numerical study of cavitation phenomenon in a flapper-nozzle pilot stage of an electrohydraulic servo-valve with an innovative flapper shape [J]. Energy Conversion and Management, 2014, 77: 31–39. DOI: 10.1016/j.enconman.2013.09.009.

WHITE F M. Fluid mechanics [M]. Boston: McGraw-Hill, 2003.

INCORPORATION F, FLUENT User’s guide version 6.3 [M]. Lebanon, NH, USA: FLUENT Inc., 2005.

VAGHEFI M, SAFARPOOR Y, AKBARI M. Numerical investigation of flow pattern and components of three-dimensional velocity around a submerged T-shaped spur dike in a 90° bend [J]. Journal of Central South University, 2016, 23(11): 2984–2998. DOI: 10.1007/s11771-016–3362-z.

MARGOT X, HOYAS S, GIL A, PATOUNA S. Numerical modelling of cavitation: Validation and parametric studies [J]. Engineering Applications of Computational Fluid Mechanics, 2012, 6(1): 15–24. DOI: 10.1080/19942060.2012.11015399.

SINGHAL A K, ATHAVALE M M, LI H, JIANG Y. Mathematical basis and validation of the full cavitation model [J]. Journal of Fluids Engineering, 2002, 124(3): 617–624. DOI: 10.1115/1.1486223.

LAUNDER B E, SPALDING D B. Lectures in mathematical models of turbulence [M]. New York: Academic Press, 1972.

FRANC J P, MICHEL J M. Fundamentals of cavitation [M]. Springer Science & Business Media, 2006.

ROUSE H. Cavitation and pressure distribution: Head forms at zero angle of yaw [M]. 1948.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yaghoubi, H., Madani, S.A.H. & Alizadeh, M. Numerical study on cavitation in a globe control valve with different numbers of anti-cavitation trims. J. Cent. South Univ. 25, 2677–2687 (2018). https://doi.org/10.1007/s11771-018-3945-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3945-y