Abstract

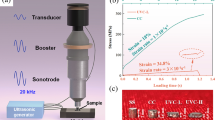

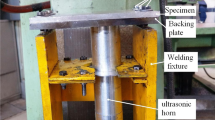

Ultrasonic vibration can reduce the forming force, decrease the friction in the metal forming process and improve the surface quality of the workpiece effectively. Tensile tests of AZ31 magnesium alloy were carried out. The stress–strain relationship, fracture modes of tensile specimens, microstructure and microhardness under different vibration conditions were analyzed, in order to study the effects of the ultrasonic vibration on microstructure and performance of AZ31 magnesium alloy under tensile deformation. The results showed that the different reductions of the true stress appeared under various ultrasonic vibration conditions, and the maximum decreasing range was 4.76%. The maximum microhardness difference among the 3 nodes selected along the specimen was HV 10.9. The fracture modes, plasticity and microstructure of AZ31 magnesium alloy also were affected by amplitude and action time of the ultrasonic vibration. The softening effect and the hardening effect occurred simultaneously when the ultrasonic vibration was applied. When the ultrasonic amplitude was 4.6 μm with short action time, the plastic deformation was dominated by twins and the softening effect was dominant. However, the twinning could be inhibited and the hardening effect became dominant in the case of high ultrasonic energy.

摘要

超声振动塑性成形技术能显著降低设备成形力, 减少模具与工件间的摩擦, 可有效提高制品的 表面质量和尺寸精度。通过进行AZ31 镁合金退火态棒材常规拉伸和不同激振方式条件下的振动拉伸 实验, 对比不同实验条件下的变形载荷曲线, 拉伸试样断裂方式, 显微硬度值, 晶粒形状、尺寸的变 化, 研究超声振动在AZ31 镁合金拉伸变形中的作用。结果表明, 施加超声振动条件不同, 真实应力 下降幅度不同, 最大降幅为4.76%。沿着试样拉伸方向所取3 个点的最大硬度差为 HV 10.9。AZ31 镁 合金的断裂方式、塑性和显微组织也受超声振动幅值和作用时间的影响。超声振动作用下, 软化效应 和硬化效应同时发生。当振幅为4.6 μm, 且作用时间较短时, 塑性变形以孪晶为主, 软化效应占主导 地位。当超声能量较高时, 孪生被抑制, 硬化效应占主导地位。

Similar content being viewed by others

References

ALFRED V. Vibration dampening: US, 2361071 [P]. 1944.

BLAHA F, LANGENECKER B. Elongation of zinc monocrystals under ultrasonic action [J]. Die Natur Wissenschafen, 1955, 42(20): 556.

LANGENECKER B. Effects of ultrasound on deformation characteristics of metals [J]. IEEE Transactions on Sonics and Ultrasonics, 1966, 13(1): 1–8. DOI: 10.1109/TSU. 1966.29367.

AHMADI F, FARZIN M, MERATIAN M, LOEIAN S M, FOROUZAN M R. Improvement of ECAP process by imposing ultrasonic vibrations [J]. The International Journal of Advanced Manufacturing Technology, 2015, 79(1–4): 503–512. DOI: 10.1007/s00170-015-6848-1.

BAGHERZADEH S, ABRINIA K, LIU Y F, HAN Q Y. The effect of combining high-intensity ultrasonic vibration with ECAE process on the process parameters and mechanical properties and microstructure of aluminum 1050 [J]. The International Journal of Advanced Manufacturing Technology, 2017, 88(1–4): 229–240. DOI: 10.1007/s00170-016-8779-x.

XIE Z, GUAN Y, ZHAI J, ZHU L, ZHONG C. Study on ultrasonic vibration assisted upsetting of 6063 aluminum alloy [J]. Procedia Engineering, 2017, 207: 490–495. DOI: 10.1016/j.proeng.2017.10.810.

IZUMI O, OYAMA K, SUZUKI Y. Effects of superimposed ultrasonic vibration on compressive deformation of metals [J]. Transactions of the Japan Institute of Metals, 1966, 7(3): 162–167. DOI: 10.2320/matertrans1960. 7.162.

DAUD Y, LUCAS M, HUANG Z. Superimposed ultrasonic oscillations in compression tests of aluminium [J]. Ultrasonics, 2006, 44: e511–e515. DOI: 10.1016/j.ultras. 2006.05.116.

DAUD Y, LUCAS M, HUANG Z H. Ultrasonic compression tests on aluminium [C]//Applied Mechanics and Materials. Trans Tech Publications. 2005, 3: 99–104. DOI:10.4028/www.scientific.net/AMM.3-4.99.

DAUD Y, LUCAS M, HUANG Z. Modelling the effects of superimposed ultrasonic vibrations on tension and compression tests of aluminium [J]. Journal of Materials Processing Technology, 2007, 186(1): 179–190. DOI: 10.1016/j.jmatprotec.2006.12.032.

HUNG J C, TSAI Y C. Investigation of the effects of ultrasonic vibration-assisted micro-upsetting on brass [J]. Materials Science and Engineering: A, 2013, 580: 125–132. DOI: 10.1016/j.msea.2013.04.074.

LIU Y X, SUSLOV S, HAN Q Y, HUA L, XU C. Comparison between ultrasonic vibration-assisted upsetting and conventional upsetting [J]. Metallurgical and Materials Transactions A, 2013, 44(7): 3232–3244. DOI: 10.1007/s11661-013-1651-9.

DJAVANROODI F, AHMADIAN H, KOOHKAN K, NASERI R. Ultrasonic assisted-ECAP [J]. Ultrasonics, 2013, 53(6): 1089–1096. DOI: 10.1016/j.ultras.2013. 02.003.

PASIERB A, WOJNAR A. An experimental investigation of deep drawing and drawing processes of thin-walled products with utilization of ultrasonic vibrations [J]. Journal of Materials Processing Technology, 1992, 34(1): 489–494. DOI: 10.1016/0924-0136(92)90145-I.

JIMMA T, KASUGA Y, IWAKI N, MIYAZAWA O, MORI E, ITO K, HATANO H. An application of ultrasonic vibration to the deep drawing process [J]. Journal of Materials Processing Technology, 1998, 80: 406–412. DOI: 10.1016/S0924-0136(98) 00195–2.

WEN T, GAO R, CHEN X. Influence of high frequency vibration on deep drawing process of AZ31 sheet at room temperature [J]. Journal of Shanghai Jiao Tong University: Science, 2012, 17: 456–460. DOI: 10.1007/s12204-012-1305-x.

DUTTA R K, PETROV R H, DELHEZ R, HERMANS M, RICHARDSON I M, BOTTGER A J. The effect of tensile deformation by in situ ultrasonic treatment on the microstructure of low-carbon steel [J]. Acta Materialia, 2013, 61(5): 1592–1602. DOI: 10.1016/j.actamat. 2012.11. 036.

LIU Y X, HAN Q Y, HUA L, XU C. Numerical and experimental investigation of upsetting with ultrasonic vibration of pure copper cone tip [J]. Ultrasonics, 2013, 53(3): 803–807. DOI: 10.1016/j.ultras. 2012.11.010.

CULP D R, GENCSOY H T. Metal deformation with ultrasound [C]//Ultrasonics Symposium. Monterey, California, USA: IEEE, 1973: 195–198. DOI: 10.1109/ULTSYM.1973.196181.

WEN T, WEI L, CHEN X, PEI C. Effects of ultrasonic vibration on plastic deformation of AZ31 during the tensile process [J]. International Journal of Minerals, Metallurgy, and Materials, 2011, 18(1): 70–76. DOI: 10.1007/s12613-011-0402-4.

DONG G, YANG Z, ZHAO J, ZHAO C. Stress–strain analysis on AA7075 cylindrical parts during hot granule medium pressure forming [J]. Journal of Central South University, 2016, 23(11): 2845–2857. DOI: 10.1007/s11771-016-3348-x.

CHEN G, ZHANG Y, XIA W, CHEN D. Microstructure and tensile creep resistance of Mg-5.5% Zn-(0.7%, 1.5%, 3.5%, 7.5%) Y alloys [J]. Journal of Central South University, 2015, 22: 4112–4122. DOI: 10.1007/s11771-015-2957-0.

YOSHIDA F. A constitutive model of cyclic plasticity [J]. International Journal of Plasticity, 2000, 16(3): 359–380. DOI: 10.1016/S0749-6419(99)00058-3.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(51375269, 51675307) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Xie, Zd., Guan, Yj., Yu, Xh. et al. Effects of ultrasonic vibration on performance and microstructure of AZ31 magnesium alloy under tensile deformation. J. Cent. South Univ. 25, 1545–1559 (2018). https://doi.org/10.1007/s11771-018-3847-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3847-z