Abstract

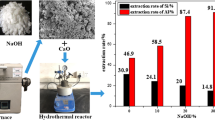

A large amount of coal gangue from coal mining and processing is regarded as waste and usually stockpiled directly. In order to recycle the valuable elements from the coal gangue, an integrated process is proposed. The process consists of three steps: 1) concentrating alumina from the coal gangue via activation roasting followed by alkali leaching of SiO2 which produces alumina concentrate for alumina extraction by the Bayer process; 2) synthesizing tobermorite whiskers from the filtrated alkali liquor containing silicate via a hydrothermal method and reusing excess caustic liquor; and 3) enriching titanium component from the Bayer process residue by sulfuric acid leaching. Alumina concentrate with 69.5% Al2O3 and mass ratio of alumina to silica (A/S) of 5.9, pure 1.1 nm tobermorite whisker and TiO2-rich material containing 33% TiO2 are produced, respectively, with the optimal parameters. Besides, the actual alumina digestion ratio of alumina concentrate reaches 80.4% at 270 ºC for 40 min in the Bayer process.

Similar content being viewed by others

References

WARD C R. Analysis and significance of mineral matter in coal seams [J]. International Journal of Coal Geology, 2002, 50(1/2/3/4): 135–168.

MESHRAM P, PUROHIT B K, SINHA M K, SAHU S K, PANDEY B D. Demineralization of low grade coal–A review [J]. Renewable & Sustainable Energy Reviews, 2015, 41: 745–761.

CHENG Hong-fei, LIU Qin-fu, YANG Jing, FROST R L. Thermogravimetric analysis of selected coal-bearing strata kaolinite [J]. Thermochimica Acta, 2010, 507-508: 84–90.

KOUKOUZAS N. Mineralogy and geochemistry of diatomite associated with lignite seams in the Komnina Lignite Basin, Ptolemais, Northern Greece [J]. International Journal of Coal Geology, 2007, 71(2/3): 276–286.

DIEHL S F, GOLDHABER M B, KOENIG A E, LOWERS H A, RUPPERT L F. Distribution of arsenic, selenium, and other trace elements in high pyrite appalachian coals: Evidence for multiple episodes of pyrite formation [J]. International Journal of Coal Geology, 2012, 94: 238–249.

BIAN Zheng-fu, INYANG H I, DANIELS J L, OTTO F, STRUTHERS S. Environmental issues from coal mining and their solutions [J]. Mining Science & Technology (China), 2010, 20(2): 215–223.

ZHOU Chun-cai, LIU Gui-jian, FANG Ting, WU Dun, LAM P K S. Partitioning and transformation behavior of toxic elements during circulated fluidized bed combustion of coal gangue [J]. Fuel, 2014, 135: 1–8.

LIU Hai-bin, LIU Zhen-ling. Recycling utilization patterns of coal mining waste in China [J]. Resources Conservation and Recycling, 2010, 54(12): 1331–1340.

LI Chao, WAN Jian-hua, SUN Heng-hu, LI Long-tu. Investigation on the activation of coal gangue by a new compound method [J]. Journal of Hazardous Materials, 2010, 179(1/2/3): 515–520.

LI Hua-jian, SUN Heng-hu, XIAO Xue-jun, CHEN Hong-xia. Mechanical properties of gangue-containing aluminosilicate based cementitious materials [J]. Journal of University of Science and Technology Beijing—Mineral, Metallurgy, Material, 2006, 13(2): 183–189.

YANG Mei, GUO Zhi-xing, DENG Yin-sheng, XING Xue-ling, QIU Ke-hui, LONG Jian-ping, LI Jun-feng. Preparation of CaO–Al2O3–SiO2 glass ceramics from coal gangue [J]. International Journal of Mineral Processing, 2012, 102-103: 112–115.

ZHOU Shuang-xi. Study on the reaction degree of calcined coal gangue powder in blended cement by selective solution method [J]. Procedia Earth & Planetary Science, 2009, 1(1): 634–639.

JI Hai-peng, FANG Ming-hao, HUANG Zhao-hui, CHEN Kai, LI Wen-juan, LIU Yan-gai. Phase transformation of coal gangue by aluminothermic reduction nitridation: Influence of sintering temperature and aluminum content [J]. Applied Clay Science, 2014, 101: 94–99.

GUO Yan-xia, YAN Ke-zhou, CUI Li, CHENG Fang-qin, LOU H H. Effect of Na2CO3 additive on the activation of coal gangue for alumina extraction [J]. International Journal of Mineral Processing, 2014, 131: 51–57.

BI Shi-wen, YU Hai-yan. Alumina production process [M]. Beijing, China: Chemical Industry Press, 2006: 32–64. (in Chinese)

LIU Fei, CAO Jian-xin, ZHU Bo. Effect of anion impurity on preparing xonotlite whiskers via hydrothermal synthesis [J]. Advances in Materials Research, 2010, 148-149: 1755–1758.

LIU Wen-li, HU Yue-hua, SUN Wei. Separation of diaspore from bauxite by selective flocculation using hydrolyzed polyacrylamide [J]. Journal of Central South University, 2014, 21(4): 1470–1476.

RAYZMAN V L, PEVZNER I Z, SIZYAKOV V M, NI L P, FILIPOVICH I K, ATURIN A V. Extracting silica and alumina from low-grade bauxite [J]. JOM, 2003, 55(8): 47–50.

LI Guang-hui, JIANG Tao, SUN Nan, FAN Xiao-hui, QIU Guanzhou. Desilication of bauxite ores bearing multi-aluminosilicates by thermochemical activation process [C]// Bearne G. Light Metals 2009. San Francisco: Wiley, 2009: 57–61.

JIANG Tao, LI Guang-hui, QIU Guan-zhou, FAN Xiao-hui, HUANG Zhu-cheng. Thermal activation and alkali dissolution of silicon from illite [J]. Applied Clay Science, 2008, 40(1/2/3/4): 81–89.

QIU Guan-zhou, JIANG Tao, LI Guang-hui, FAN Xiao-hui, HUANG Zhu-cheng. Activation and removal of silicon in kaolinite by thermochemical process [J]. Scandinavian Journal of Metallurgy, 2004, 33(2): 121–128.

LI Guang-hui, ZENG Jing-hua, LUO Jun, LIU Ming-xia, JIANG Tao, QIU Guan-zhou. Thermal transformation of pyrophyllite and alkali dissolution behavior of silicon [J]. Applied Clay Science, 2014, 99: 282–288.

MERLINO S, BONACCORSI E, ARMBRUSTER T. The real structure of tobermorite 11Å normal and anomalous forms, OD character and polytypic modifications [J]. European Journal of Mineralogy, 2001, 13(3): 577–590.

NOCUÒ-WCZELIK W. Effect of Na and Al on the phase composition and morphology of autoclaved calcium silicate hydrates [J]. Cement and Concrete Research, 1999, 29(11): 1759–1767.

YAMAZAKI S, TORAYA H. Determination of positions of zeolitic calcium atoms and water molecules in hydrothermally formed aluminum-substiqtuted tobermorite-1.1 nm using synchrotron radiation powder diffraction data [J]. Journal of the American Ceramic Society, 2001, 84(11): 2685–2690.

LI Guang-hui, LIU Ming-xia, RAO Ming-jun, JIANG Tao, ZHUANG Jin-qiang, ZHANG Yuan-bo. Stepwise extraction of valuable components from red mud based onreductive roasting with sodium salts [J]. Journal of Hazardous Materials, 2014, 280: 774–780.

AGATZINI-LEONARDOU S, OUSTADAKIS P, TSAKIRIDIS P, MARKOPOULOS C. Titanium leaching from red mud by diluted sulfuric acid at atmospheric pressure [J]. Journal of Hazardous Materials, 2008, 157(2/3): 579–586.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(51234008, 51174230) supported by the National Natural Science Foundation of China; Project(NCET-11-0515) supported by the Program for New Century Excellent Talents in University, China; Project supported by Co-Innovation Center for Clean and Efficient Utilization of Strategic Metal Mineral Resources, China

Rights and permissions

About this article

Cite this article

Luo, J., Li, Gh., Jiang, T. et al. Conversion of coal gangue into alumina, tobermorite and TiO2-rich material. J. Cent. South Univ. 23, 1883–1889 (2016). https://doi.org/10.1007/s11771-016-3243-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-016-3243-5