Abstract

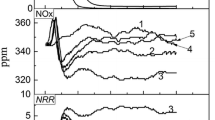

The properties of circulating gas have a significant effect on sintering with flue gas recirculation, and the influence of CO in sintering process was investigated. The results show that the post-combustion of CO conducts in sinter zone when flue gas passes through the sintering bed, which releases much heat and reduces the consumption of solid fuel. The ratio of coke breeze can be reduced from 5% to 4.7% with 2% CO in circulating flue gas. In addition, with the increase of CO content in circulating flue gas, the combustion efficiency of fuel is improved, and the flame front is increased slightly while still matches with the heat transfer front. These are beneficial to increasing the maximum temperature and prolonging the high temperature duration, especially in the upper layer of sintering bed. As a consequence, the productivity, vertical sintering velocity and quality of sinter are improved.

Similar content being viewed by others

References

REN Li. A low carbon economy and sustainable development economy of China [J]. Social Scientists, 2009, 12(2): 47–50. (in Chinese)

FAN Xiao-hui, YU Zhi-yuan, GAN Min, CHEN Xun-ling, JIANG Tao. Energy saving and emission reduction status and development direction in iron ore sintering [C]// Proceedings of the 2011 Annual Conference on Sintering & Pelletizing Technology of China. Changsha: National Sintering and Pellets Information Network, 2011: 1–4. (in Chinese)

HU Jun-ge, ZHANG Dong-li, QU Yu-ling. The technical development of removing SO2 of flue gas [J]. Metallurgy Series, 2009(3): 36–40. (in Chinese)

TANG Jing-fang, FU Lin-tao, LI Fu-zhi. The application of NID desulfurization process in 3rd sintering plant of WISCO [J]. Sinter and Pellets, 2009, 34(5): 13–16. (in Chinese)

CAPPEL F, WESEL H. EOSR flue gas circulation optimizes sintering-A new craft to strengthen the environment protection of iron ore sintering [J]. Sintering and Pelleting, 1993(4): 33–36. (in Chinese)

WERZ H J, OTTO J, RENGERSEN J. Environmental protection in iron ore sintering by waste gas recirculation [J]. Environmental protection Metallurgical Plant and Technology (MPT) International, 1995, 4: 120–126.

LOVEL R, VINING K, DELL’AMICO M. Iron ore sintering with charcoal [J]. Mineral Processing and Extractive Metallurgy (Trans Inst Min Metall C), 2007, 116(2): 85–92.

YU Yong-mei, ZHENG Ming-hui, LI Xian-wei, HE Xiao-lei. Operating condition influences on PCDD/Fs emissions from sinter pot tests with hot flue gas recycling [J]. Journal of Environmental Sciences, 2012, 24(5): 875–881

MENAD N, TAYIBI H, FERMANDO G C, HERNANDEZ A. Minimization methods for emissions generated from sinter strands: A review [J]. Journal of Cleaner Production, 2006, 14(8): 740–747.

JIN Ming-fang, LI Guang-sen, JIANG Xin, WANG Xiao-ming, SHEN Feng-man. The analysis of influencing factor on process of the original liquid formation in sintering [J]. Energy Saving, 2008(4): 7–9. (in Chinese)

BRUNNBAUER G, EHLER W, ZWITTAG E, SCHMID H, REIDETSCHLAEGER J, KAINZ K. New waste-gas recycling system for the sinter plant at Voestalpine Stah [J]. Metallurgical Plant and Technology International, 2006, 29(4): 38–42.

FLEISCHANDER A, AICHINGER C, ZWITTAG E. New developments for achieving environmentally friendly sinter production-Eposint and MEROS [J]. China Metallurgy, 2008, 18(11): 41–46.

ZHANG He-lei, RAO Ming-jun, FAN Zhen-yu, ZHANG Yuan-bo, LI Guang-hui, JIANG Tao. Effects of circulated flue gas components on iron ore sintering [J]. ISIJ International, 2012, 25(12): 2139–2144

PAUL E. NILLES. Alternative Technologies in Iron and Steel making [J]. Metallurgical and Materials Transactions, 1996, 27: 541–553

TANG Xian-rong, WANG Du-yang, ZHANG Qing-chen. Sintering Theory and Technology [M]. Changsha: Central South University Press, 1992: 23–44. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(51174253, 51304245) supported by the National Natural Science Foundation of China; Project(2013bjjxj015) supported by the Outstanding and Creative Doctor Scholarship of Central South University, China; Project supported by the Hunan Provincial Innovation Foundation for Postgraduate, China

Rights and permissions

About this article

Cite this article

Fan, Xh., Yu, Zy., Gan, M. et al. Combustion behavior and influence mechanism of CO on iron ore sintering with flue gas recirculation. J. Cent. South Univ. 21, 2391–2396 (2014). https://doi.org/10.1007/s11771-014-2192-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-2192-0