Abstract

Heat pipe utilizes continuous phase change process within a small temperature drop to achieve high thermal conductivity. For decades, heat pipes coupled with novel emerging technologies and methods (using nanofluids and self-rewetting fluids) have been highly appreciated, along with which a number of advances have taken place. In addition to some typical applications of thermal control and heat recovery, the heat pipe technology combined with the sorption technology could efficiently improve the heat and mass transfer performance of sorption systems for heating, cooling and cogeneration. However, almost all existing studies on this combination or integration have not concentrated on the principle of the sorption technology with acting as the heat pipe technology for continuous heat transfer. This paper presents an overview of the emerging working fluids, the major applications of heat pipe, and the advances in heat pipe type sorption system. Besides, the ongoing and perspectives of the solid sorption heat pipe are presented, expecting to serve as useful guides for further investigations and new research potentials.

Similar content being viewed by others

References

Gaugler R S. Heat transfer device. US Patent, 2350348, 1944

Grover G M, Cotter T P, Ericson G F. Structures of very high thermal conductance. Journal of Applied Physics, 1964, 35: 1190–1191

Reay D A, Kew P A, McGlen R J. Heat Pipes: Theory, Design and Applications. 6th ed. Whitley Bay: Elsevier, 2013

Vasiliev L L, Kakac S. Heat Pipes and Solid Sorption Transformations: Fundamentals and Practical Applications. Florida: Taylor & Francis Group, 2013

Faghri A. Heat pipes: review, opportunities and challenges. Frontiers in Heat Pipes, 2014, 5(1): 1–48

Faghri A, Chen M M, Morgan M. Heat transfer characteristics in two-phase closed conventional and concentric annular thermosyphons. Journal of Heat Transfer, 1989, 111(3): 611–618

El-Genk M S, Saber H H. Flooding limit in closed, two-phase flow thermosyphons. International Journal of Heat and Mass Transfer, 1997, 40(9): 2147–2164

Nguyen-Chi H, Groll M. Entrainment or flooding limit in a closed two-phase thermosyphon. Journal of Heat Recovery Systems, 1981, 1(4): 275–286

Shatto D P, Besly J A, Peterson G P. Visualization study of flooding and entrainment in a closed two-phase thermosyphon. Journal of Thermophysics and Heat Transfer, 1997, 11(4): 579–581

Meunier F. Solid sorption heat powered cycles for cooling and heat pumping applications. Applied Thermal Engineering, 1998, 18(9–10): 715–729

Wang L W, Wang R Z, Oliveira R G. A review on adsorption working pairs for refrigeration. Renewable & Sustainable Energy Reviews, 2009, 13(3): 518–534

Yan T, Wang R Z, Li T X, Wang L W, Fred I T. A review of promising candidate reactions for chemical heat storage. Renewable & Sustainable Energy Reviews, 2015, 43: 13–31

Wang R Z, Wang L W, Wu J Y. Adsorption Refrigeration Theory and Applications. Beijing: Science Press, 2007

Critoph R E. The use of thermosyphon heat pipes to improve the performance of a carbon-ammonia adsorption refrigerator. In: IV Minsk International Seminar “Heat Pipes, Heat Pumps, Refrigerators”, Minsk, Belarus, 2000

Wang R Z. Efficient adsorption refrigerators integrated with heat pipes. Applied Thermal Engineering, 2008, 28(4): 317–326

Wang D C, Xia Z Z, Wu J Y, Wang R Z, Zhai H, Dou W D. Study of a novel silica gel–water adsorption chiller. Part I. Design and performance prediction. International Journal of Refrigeration, 2005, 28(7): 1073–1083

Yang G Z, Xia Z Z, Wang R Z, Keletigui D, Wang D C, Dong Z H, Yang X. Research on a compact adsorption room air conditioner. Energy Conversion and Management, 2006, 47(15–16): 2167–2177

Wang L W, Wang R Z, Lu Z S, Xu Y X, Wu J Y. Split heat pipe type compound adsorption ice making test unit for fishing boats. International Journal of Refrigeration, 2006, 29(3): 456–468

Li T X, Wang R Z, Wang L W, Lu Z S, Chen C J. Performance study of a high efficient multifunction heat pipe type adsorption ice making system with novel mass and heat recovery processes. International Journal of Thermal Sciences, 2007, 46(12): 1267–1274

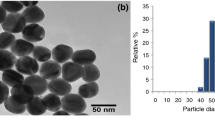

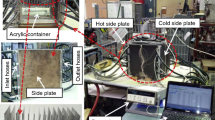

Yu Y, Wang L W, Jiang L, Gao P, Wang R Z. The feasibility of solid sorption heat pipe for heat transfer. Energy Conversion and Management, 2017, 138: 148–155

Yu Y, Wang L W, An G L. Experimental study on sorption and heat transfer performance of NaBr-NH3 for solid sorption heat pipe. International Journal of Heat and Mass Transfer, 2018, 117: 125–131

Jouhara H, Chauhan A, Nannou T, Almahmoud S, Delpech B, Wrobel L C. Heat pipe based systems—advances and applications. Energy, 2017, 128: 729–754

Gupta N K, Tiwari A K, Ghosh S K. Heat transfer mechanisms in heat pipes using nanofluids—a review. Experimental Thermal and Fluid Science, 2018, 90: 84–100

Chien H T, Tsai C I, Chen P H, Chen P Y. Improvement on thermal performance of a disk-shaped miniature heat pipe with nanofluid. In: Proceedings of 5th International Conference on Electronic Packaging Technology, Shanghai, China, 2003

Putra N, Septiadi W N, Rahman H, Irwansyah R. Thermal performance of screen mesh wick heat pipes with nanofluids. Experimental Thermal and Fluid Science, 2012, 40: 10–17

Putra N, Saleh R, Septiadi W N, Okta A, Hamid Z. Thermal performance of biomaterial wick loop heat pipes with water-base Al2O3 nanofluids. International Journal of Thermal Sciences, 2014, 76: 128–136

Mashaei P R, Shahryari M, Fazeli H, Hosseinalipour S M. Numerical simulation of nanofluid application in a horizontal mesh heat pipe with multiple heat sources: a smart fluid for high efficiency thermal system. Applied Thermal Engineering, 2016, 100: 1016–1030

Mashaei P R, Shahryari M, Madani S. Numerical hydrothermal analysis of water-Al2O3 nanofluid forced convection in a narrow annulus filled by porous medium considering variable properties. Journal of Thermal Analysis and Calorimetry, 2016, 126(2): 891–904

Mashaei P R, Shahryari M, Madani S. Analytical study of multiple evaporator heat pipe with nanofluid: a smart material for satellite equipment cooling application. Aerospace Science and Technology, 2016, 59: 112–121

Ramachandran R, Ganesan K, Rajkumar M R, Asirvatham L G, Wongwises S. Comparative study of the effect of hybrid nanoparticle on the thermal performance of cylindrical screen mesh heat pipe. International Communications in Heat and Mass Transfer, 2016, 76: 294–300

Sözen A, Menlik T, Gürü M, Boran K, Kılıç F, Aktaş M, Çakır M T. A comparative investigation on the effect of fly-ash and alumina nanofluids on the thermal performance of two-phase closed thermosyphon heat pipes. Applied Thermal Engineering, 2016, 96: 330–337

Ghanbarpour M, Khodabandeh R, Vafai K. An investigation of thermal performance improvement of a cylindrical heat pipe using Al2O3 nanofluid. Heat and Mass Transfer, 2017, 53(3): 973–983

Poplaski L M, Benn S P, Faghri A. Thermal performance of heat pipes using nanofluids. International Journal of Heat and Mass Transfer, 2017, 107: 358–371

Senthil R, Ratchagaraja D, Silambarasan R, Manikandan R. Contemplation of thermal characteristics by filling ratio of Al2O3 nanofluid in wire mesh heat pipe. Alexandria Engineering Journal, 2016, 55(2): 1063–1068

Kumaresan G, Venkatachalapathy S, Asirvatham L G, Wongwises S. Comparative study on heat transfer characteristics of sintered and mesh wick heat pipes using CuO nanofluids. International Communications in Heat and Mass Transfer, 2014, 57: 208–215

Venkatachalapathy S, Kumaresan G, Suresh S. Performance analysis of cylindrical heat pipe using nanofluids—an experimental study. International Journal of Multiphase Flow, 2015, 72: 188–197

Kumaresan G, Venkatachalapathy S, Asirvatham L G. Experimental investigation on enhancement in thermal characteristics of sintered wick heat pipe using CuO nanofluids. International Journal of Heat and Mass Transfer, 2014, 72: 507–516

Alizad K, Vafai K, Shafahi M. Thermal performance and operational attributes of the startup characteristics of flat-shaped heat pipes using nanofluids. International Journal of Heat and Mass Transfer, 2012, 55(1–3): 140–155

Brahim T, Jemni A. Numerical case study of packed sphere wicked heat pipe using Al2O3 and CuO based water nanofluid. Case Studies in Thermal Engineering, 2016, 8: 311–321

Kole M, Dey T K. Thermal performance of screen mesh wick heat pipes using water-based copper nanofluids. Applied Thermal Engineering, 2013, 50(1): 763–770

Senthilkumar R, Vaidyanathan S, Sivaraman B. Effect of inclination angle in heat pipe performance using copper nanofluid. Procedia Engineering, 2012, 38: 3715–3721

Klinbun J, Terdtoon P. Experimental study of copper nano-fluid on thermosyphons thermal performance. Engineering Journal (New York), 2017, 21(1): 255–264

Riehl R R, Santos N. Water-copper nanofluid application in an open loop pulsating heat pipe. Applied Thermal Engineering, 2012, 42: 6–10

Karthikeyan V K, Ramachandran K, Pillai B C, Brusly Solomon A. Effect of nanofluids on thermal performance of closed loop pulsating heat pipe. Experimental Thermal and Fluid Science, 2014, 54: 171–178

Solomon A B, Ramachandran K, Asirvatham L G, Pillai B C. Numerical analysis of a screen mesh wick heat pipe with Cu/water nanofluid. International Journal of Heat and Mass Transfer, 2014, 75: 523–533

Wan Z, Deng J, Li B, Xu Y, Wang X, Tang Y. Thermal performance of a miniature loop heat pipe using water-copper nanofluid. Applied Thermal Engineering, 2015, 78: 712–719

Abe Y, Iwasaki A, Tanaka K. Microgravity experiments on phase change of self-rewetting fluids. Annals of the New York Academy of Sciences, 2004, 1027(1): 269–285

Hu Y, Huang K, Huang J. A review of boiling heat transfer and heat pipes behaviour with self-rewetting fluids. International Journal of Heat and Mass Transfer, 2018, 121: 107–118

Wu S C. Study of self-rewetting fluid applied to loop heat pipe. International Journal of Thermal Sciences, 2015, 98: 374–380

Senthilkumar R, Vaidyanathan S, Sivaraman B. Comparative study on heat pipe performance using aqueous solutions of alcohols. Heat and Mass Transfer, 2012, 48(12): 2033–2040

Peyghambarzadeh S M, Hallaji H, Bohloul M R, Aslanzadeh N. Heat transfer and Marangoni flow in a circular heat pipe using selfrewetting fluids. Experimental Heat Transfer, 2017, 30(3): 218–234

Xin G M, Qin Q Y, Zhang L S, Ji W X. Thermal characteristics of gravity heat pipes with self-rewetting fluid at small inclination angles. Journal of Engineering Thermophysics, 2013, 36(6): 1282–1285

Su X J, Zhang M, Han W, Guo X. Experimental study on the heat transfer performance of an oscillating heat pipe with self-rewetting nanofluid. International Journal of Heat and Mass Transfer, 2016, 100: 378–385

Tian F Z, Xin G M, Hai Q, Cheng L. An investigation of heat transfer characteristic of cross internal helical microfin gravity heat pipe with self-rewetting fluid. Advanced Materials Research, 2013, 765–767: 189–192

Zhao J, Qu J, Rao Z. Experiment investigation on thermal performance of a large-scale oscillating heat pipe with selfrewetting fluid used for thermal energy storage. International Journal of Heat and Mass Transfer, 2017, 108: 760–769

Sohel Murshed S M, Nieto De Castro C A. A critical review of traditional and emerging techniques and fluids for electronics cooling. Renewable & Sustainable Energy Reviews, 2017, 78: 821–833

Faghri A. Review and advances in heat pipe science and technology. Journal of Heat Transfer, 2012, 134(12): 123001

Chen X, Ye H, Fan X, Ren T, Zhang G. A review of small heat pipes for electronics. Applied Thermal Engineering, 2016, 96: 1–17

Maydanik Y F, Chernysheva M A, Pastukhov V G. Review: loop heat pipes with flat evaporators. Applied Thermal Engineering, 2014, 67(1–2): 294–307

Siedel B, Sartre V, Lefèvre F. Literature review: steady-state modelling of loop heat pipes. Applied Thermal Engineering, 2015, 75: 709–723

Becker S, Vershinin S, Sartre V, Laurien E, Bonjour J, Maydanik Y F. Steady state operation of a copper-water LHP with a flat-oval evaporator. Applied Thermal Engineering, 2011, 31(5): 686–695

Maydanik Y F, Vershinin S. Development and investigation of copper-water loop heat pipes with high operating characteristics. Heat Pipe Science and Technology, An International Journal, 2010, 1(2): 151–162

Pastukhov V G, Maydanik Y F. Low-noise cooling system for PC on the base of loop heat pipe. Applied Thermal Engineering, 2007, 27: 894–901

Su Q, Chang S, Zhao Y, Zheng H, Dang C. A review of loop heat pipes for aircraft anti-icing applications. Applied Thermal Engineering, 2018, 130: 528–540

Reyes M, Alonso D, Arias J, Velazquez A. Experimental and theoretical study of a vapour chamber based heat spreader for avionics applications. Applied Thermal Engineering, 2012, 37: 51–59

Yang K S, Yang T Y, Tu C W, Yeh C T, Lee M T. A novel flat polymer heat pipe with thermal via for cooling electronic devices. Energy Conversion and Management, 2015, 100: 37–44

Qu J, Wu H Y, Wang Q. Experimental investigation of siliconbased micro-pulsating heat pipe for cooling electronics. Nanoscale and Microscale Thermophysical Engineering, 2012, 16(1): 37–49

Zhu R, Chen J, Long Y, Hu X. Oscillation heat transfer dynamic model for the new type oscillation looped heat pipe with double liquid slugs. Journal of Central South University, 2012, 19(11): 3194–3201

Zhao X, Deng Y, Zhu H. Pressure distribution and flow characteristics of closed oscillating heat pipe during starting process at different vacuum degrees. Applied Thermal Engineering, 2016, 93: 166–173

Ebrahimi K, Jones G F, Fleischer A S. A review of data center cooling technology, operating conditions and the corresponding low-grade waste heat recovery opportunities. Renewable & Sustainable Energy Reviews, 2014, 31: 622–638

Sevencan S, Lindbergh G, Lagergren C, Alvfors P. Economic feasibility study of a fuel cell-based combined cooling, heating and power system for a data centre. Energy and Building, 2016, 111: 218–223

Whitney J, Delforge P. Data Center Efficiency Assessment. New York: Natural Resources Defense Council, 2014

Daraghmeh H M, Wang C. A review of current status of free cooling in datacenters. Applied Thermal Engineering, 2017, 114: 1224–1239

Zhou F, Ma G, Wang S. Entropy generation rate analysis of a thermosyphon heat exchanger for cooling a telecommunication base station. International Journal of Exergy, 2017, 22(2): 139–157

Zhou F, Li C, Zhu W, Zhou J, Ma G, Liu Z. Energy-saving analysis of a case data center with a pump-driven loop heat pipe system in different climate regions in China. Energy and Building, 2018, 169: 295–304

Zhang L Y, Liu Y Y, Guo X, Meng X Z, Jin L W, Zhang Q L, Hu W J. Experimental investigation and economic analysis of gravity heat pipe exchanger applied in communication base station. Applied Energy, 2017, 194: 499–507

Zhang L Y, Liu Y Y, Jin L W, Liu X, Meng X, Zhang Q. Economic analysis of gravity heat pipe exchanger applied in communication base station. Energy Procedia, 2016, 88: 518–525

Tong Z, Ding T, Li Z, Liu X H. An experimental investigation of an R744 two-phase thermosyphon loop used to cool a data center. Applied Thermal Engineering, 2015, 90: 362–365

Zhang H, Shi Z, Liu K, Shao S, Jin T, Tian C. Experimental and numerical investigation on a CO2 loop thermosyphon for free cooling of data centers. Applied Thermal Engineering, 2017, 111: 1083–1090

Zhang H, Shao S, Tian C, Zhang K. A review on thermosyphon and its integrated system with vapor compression for free cooling of data centers. Renewable & Sustainable Energy Reviews, 2018, 81(1): 789–798

Zhang H, Shao S, Xu H, Zou H, Tian C. Integrated system of mechanical refrigeration and thermosyphon for free cooling of data centers. Applied Thermal Engineering, 2015, 75: 185–192

Zhang H, Shao S, Xu H, Zou H, Tang M, Tian C. Numerical investigation on fin tube three-fluid heat exchanger for hybrid source HVAC & R systems. Applied Thermal Engineering, 2016, 95: 157–164

Blet N, Lips S, Sartre V. Heat pipes for temperature homogenization: a literature review. Applied Thermal Engineering, 2017, 118: 490–509

Chaudhry H N, Hughes B R, Ghani S A. A review of heat pipe systems for heat recovery and renewable energy applications. Renewable & Sustainable Energy Reviews, 2012, 16(4): 2249–2259

Liu Y, Zhang H. Experimental studies on the isothermal and heat transfer performance of trough solar power collectors. Advanced Materials Research, 2014, 1044–1045: 320–326

Rittidech S, Wannapakne S. Experimental study of the performance of a solar collector by closed-end oscillating heat pipe (CEOHP). Applied Thermal Engineering, 2007, 27(11–12): 1978–1985

Kargarsharifabad H, Mamouri S J, Shafii M B, Rahni M T. Experimental investigation of the effect of using closed-loop pulsating heat pipe on the performance of a flat plate solar collector. Journal of Renewable and Sustainable Energy, 2013, 5(1): 013106

He W, Zhou J, Hou J, Chen C, Ji J. Theoretical and experimental investigation of a thermoelectric cooling and heating system driven by solar. Applied Energy, 2013, 107: 89–97

Ong K S. Review of solar, heat pipe and thermoelectric hybrid systems for power generation and heating. International Journal of Low Carbon Technologies, 2016, 11(4): 460–465

WBCSD. Energy Efficiency in Buildings Facts & Trends. World Business Council for Sustainable Development’s Report. Switzerland: Atar Roto Presse SA, 2008

O’Connor D, Calautit J K S, Hughes B R. A review of heat recovery technology for passive ventilation applications. Renewable & Sustainable Energy Reviews, 2016, 54: 1481–1493

Jafari D, Franco A, Filippeschi S, Di Marco P. Two-phase closed thermosyphons: a review of studies and solar applications. Renewable & Sustainable Energy Reviews, 2016, 53: 575–593

Firouzfar E, Soltanieh M, Noie S H, Saidi S H. Energy saving in HVAC systems using nanofluid. Applied Thermal Engineering, 2011, 31(8–9): 1543–1545

Byrne P, Miriel J, Lénat Y. Experimental study of an air-source heat pump for simultaneous heating and cooling–part 2: dynamic behavior and two-phase thermosiphon defrosting technique. Applied Thermal Engineering, 2011, 88: 3072–3078

Jouhara H, Merchant H. Experimental investigation of a thermosyphon based heat exchanger used in energy efficient air handling units. Energy, 2012, 39(1): 82–89

Danielewicz J, Sayegh M A, Sniechowska B, Szulgowska-Zgrzywa M, Jouhara H. Experimental and analytical performance investigation of air to air two phase closed thermosyphon based heat exchangers. Energy, 2014, 77: 82–87

Meena P, Tammasaeng P, Kanphirom J, Ponkho A, Setwong S. Enhancement of the performance heat transfer of a thermosyphon with fin and without fin heat exchangers using Cu-nanofluid as working fluids. Journal of Engineering Thermophysics, 2014, 23(4): 331–340

Vasiliev L L, Vasiliev L Jr. Sorption heat pipe—a new thermal control device for space and ground application. International Journal of Heat and Mass Transfer, 2005, 48(12): 2464–2472

Vasiliev L L, Vasiliev L Jr. The sorption heat pipe—a new device for thermal control and active cooling. Superlattices and Microstructures, 2004, 35(3–6): 485–495

Vasiliev L L. Sorption refrigerators with heat pipe thermal control. In: Cryogenics and Refrigeration–Proceedings of ICCR. Beijing: Science Press, 2003, 405–415

Vasiliev L L. Solar sorption refrigerator. In: Proceeding of 5th Minsk International Seminar “Heat Pipes, Heat Pumps, Refrigerators”, Minsk, Belarus, 2003

Vasiliev L L, Mishkinis D A, Antukh A A, Vasiliev L L Jr. Solar–gas solid sorption heat pump. Applied Thermal Engineering, 2001, 21(5): 573–583

Vasiliev L L, Kanonchik L E, Antuh A A, Kulakov A G, Kulikovsky V K. Waste heat driven solid sorption coolers containing heat pipes for thermo control. Adsorption, 1995, 1(4): 303–312

Vasiliev L L. Electronic cooling system with a loop heat pipe and solid sorption cooler. In: 11th International Heat Pipe Conference, Musachinoshi, Tokyo, Japan, 1999

Vasiliev L L. Heat pipes and solid sorption machines. Heat Transfer Research, 2004, 35(5–6): 393–405

Wang L W, Wang R Z, Wu J Y, Xia Z Z, Wang K. A new type adsorber for adsorption ice maker on fishing boats. Energy Conversion and Management, 2005, 46(13–14): 2301–2316

Wang K, Wu J Y, Xia Z Z, Li S L, Wang R Z. Design and performance prediction of a novel double heat pipes type adsorption chiller for fishing boats. Renewable Energy, 2008, 33(4): 780–790

Lu Z S, Wang R Z, Li T X, Wang L W, Chen C J. Experimental investigation of a novel multifunction heat pipe solid sorption icemaker for fishing boats using CaCl2/activated carbon compound–ammonia. International Journal of Refrigeration, 2007, 30(1): 76–85

E J, Zhao X, Liu H, Chen J, Zuo W, Peng Q. Field synergy analysis for enhancing heat transfer capability of a novel narrow-tube closed oscillating heat pipe. Applied Energy, 2016, 175: 218–228

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51576120).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Y., An, G. & Wang, L. Major applications of heat pipe and its advances coupled with sorption system: a review. Front. Energy 13, 172–184 (2019). https://doi.org/10.1007/s11708-019-0610-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-019-0610-6