Abstract

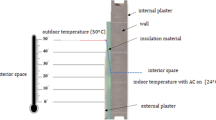

In this paper, the influence of different external wall insulation materials on the energy consumption of a newly built apartment in Germany is investigated. Three types of insulation materials commonly used in Germany including mineral fiber, polyurethane, and vacuum insulation panel are chosen for the case studies. An energy analysis model is established to clarify the primary energy use for production of the insulation materials and for building space heating. The calculation results show that the energy consumption for insulation material production increases with the insulation thickness, whereas the energy use for space heating decreases with the insulation thickness. Thus, there exists an optimum thickness to get the lowest total energy consumption for each kind of insulation material. The ascending order of the total energy consumption of the three materials is mineral fiber, polyurethane, and vacuum insulation panel. However, the optimum insulation thicknesses for the three insulation materials show a verse order at a certain heat transfer coefficient of the base envelope. The energy payback time (EPT) is proposed to calculate the payback time of the primary energy use for insulation material production. Mineral fiber has the shortest time, followed by polyurethane and vacuum insulation panel. The EPTS is 10, 19 and 21 years, respectively when the heat transfer coefficient of the base envelope is 0.2 W/(m2·K). In addition, the simulated results show that the theoretical value and the simulated value are basically identical.

Similar content being viewed by others

References

Khasreen M M, Banfill P F G, Menzies G F BanfillPhillip F G, Menzies G F. Life-cycle assessment and the environmental impact of buildings: a review. Sustainability, 2009, 1(3): 674–701

Klöpffer W. Therole of SETAC in the development of LCA. International Journal of Life Cycle Assessment, 2006, 11(S1): 116–122

Gu D, Zhu Y, Gu L. Life cycle assessment for China building environment impacts. Journal of Tsinghua University (Science & Technology), 2006, 46(12): 1953–1956

Robin D, Michael A, Selwyn T. Automating building life cycle energy assessment. In: International Council for Research and Innovation in Building and Construction CIB w78 Conference. Aarhus School of Architecture, Denmark, 2002, 1–8

Carol M. LCA of innovative high energy performance envelope. 2007, http://www.lcm2007.org/paper/318.pdf

Fay R, Treloar G, Iyerraniga U. Life-cycle energy analysis of buildings: a case study. Building Research and Information, 2000, 28(1): 31–41

Gu D J, Gu L J, Zhu Y X. A life cycle assessment method for buildings. In: Proceedings of Building Simulation. Beijing, China, 2007, 1595–1600

Shi J F, Li A G, Chen S L. Research on the thickness of economical insulation layer of external wall in Xi’an. Architecture Technology & Design, 2008, 9(9):78–83

Zhang X. Assessment method of building energy consumption based on LCA. Refrigeration Air Conditioning & Electric Power Machinery, 2002, 23(4):1–3

Zheng G Z, Jing Y Y, Huang H X, Gao Y F. Application of life cycle assessment (LCA) and extenics theory for building energy conservation assessment. Energy, 2009, 34(11): 1870–1879

Tarantini M, Loprieno A D, Porta P L. A life cycle approach to green public procurement of building materials and elements: a case study on windows. Energy, 2011, 36(5): 2473–2482

Malmqvist T, Glaumann M, Scarpellini S, Zabalza I, Aranda A, Llera E, Díaz S. Life cycle assessment in buildings: the ENSLIC simplified method and guidelines. Energy, 2011, 36(4): 1900–1907

Tsai W H, Lin S J, Liu J Y, Lin W R, Lee K C. Incorporating life cycle assessments into building project decision-making: an energy consumption and CO2 emission perspective Energy, 2011, 36(5): 3022–3029

Zabalza I, Aranda A, Scarpellini S, Díaz S. Life cycle assessment in building sector: state of the art and assessment of environmental impact for building materials. In: The 1st International Exergy, Life Cycle Assessment, and Sustainability Workshop & Symposium (ELCAS) 2009. Nisyros, Greece, 2009

Huberman N, Pearlmutter D. A life-cycle energy analysis of building materials in the Negev desert. Energy and Building, 2008, 40(5): 837–848

Ardente F, Beccali M, Cellura M, Mistretta M. Building energy performance: a LCA case study of kenaf-fibres insulation board. Energy and Building, 2008, 40(1): 1–10

Blengini G A, Di Carlo T. The changing role of life cycle phases, subsystems and materials in the LCA of low energy buildings. Energy and Building, 2010, 42(6): 869–880

Ramesh T, Prakash R, Shukla K K. Life cycle energy analysis of buildings: an overview. Energy and Building, 2010, 42(10): 1592–1600

ISO 14040. Environmental management life cycle assessment principles and framework. In: International Standards Organization. Brussels, Belgium, 2006

Siraki K. Life cycle assessment of residential buildings. Dissertation for Doctoral Degree. Bochum: Ruhr-University Bochum, 2007, 3

Acknowledgments

This work was supported by the Natural Science Foundation of Tianjin, China (Grant No.17JCZDJC31400) and the Scientific Special Commissioner of Tianjin, China (16JCTPJC52800).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, J., Tang, J. Influence of envelope insulation materials on building energy consumption. Front. Energy 11, 575–581 (2017). https://doi.org/10.1007/s11708-017-0473-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-017-0473-7