Abstract

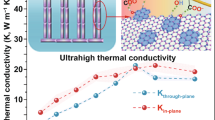

A series of flexible poly(m-phenylene isophthalamide) (PMIA)-based composites with different sizes and mass fractions of hexagonal boron nitride (hBN) were successfully manufactured for the first time via the casting technique. The effects of modified hBN particles on microstructure, mechanical properties, dielectric properties and thermal conductivities of fabricated composites were investigated. The results indicate that modified hBN particles manifest good compatibility with the PMIA matrix. The Young’s modulus and Theat-resistance index of PMIA-based composites are increased with increasing the mass fraction of hBN particles. Due to additional thermal conductive paths and networks formed by nano-sized hBN particles, the K-m/n-hBN-30 composite displays the thermal conductivity of 0.94 W·m-1·K-1, higher than that of the K-m-hBN-30 composite (0.86 W·m-1·K-1), and more than 4 times higher than that of neat PMIA. Moreover, the obtained PMIA-based composites also show low dielectric constant and ideal dielectric loss. Owing to the excellent comprehensive performance, hBN/PMIA composites present potential applications in the broad field of electronic materials.

Similar content being viewed by others

References

García J M, García F C, Serna F, et al. High-performance aromatic polyamides. Progress in Polymer Science, 2010, 35(5): 623–686

Wang X, Si Y, Wang X, et al. Tuning hierarchically aligned structures for high-strength PMIA–MWCNT hybrid nanofibers. Nanoscale, 2013, 5(3): 886–889

Lin C E, Wang J, Zhou M Y, et al. Poly(m-phenylene isophthalamide) (PMIA): A potential polymer for breaking through the selectivity–permeability trade-off for ultrafiltration membranes. Journal of Membrane Science, 2016, 518: 72–78

Tang X, Si Y, Ge J, et al. In situ polymerized superhydrophobic and superoleophilic nanofibrous membranes for gravity driven oil–water separation. Nanoscale, 2013, 5(23): 11657–11664

Nimmanpipug P, Tashiro K, Rangsiman O. Factors governing the three-dimensional hydrogen-bond network structure of poly(mphenylene isophthalamide) and a series of its model compounds (4): similarity in local conformation and packing structure between a complicated three-arm model compound and the linear model compounds. The Journal of Physical Chemistry B, 2006, 110(42): 20858–20864

Kang W, Deng N, Ma X, et al. A thermostability gel polymer electrolyte with electrospun nanofiber separator of organic Fdoped poly-m-phenyleneisophthalamide for lithium-ion battery. Electrochimica Acta, 2016, 216: 276–286

Mazzocchetti L, Benelli T, Maccaferri E, et al. Poly-m-aramid electrospun nanofibrous mats as high-performance flame retardants for carbon fiber reinforced composites. Composites Part B: Engineering, 2018, 145: 252–260

Chen W, Weng W. Ultrafine lauric–myristic acid eutectic/poly (meta-phenylene isophthalamide) form-stable phase change fibers for thermal energy storage by electrospinning. Applied Energy, 2016, 173: 168–176

Mittal V, ed. High Performance Polymers and Engineering Plastics. Beverly, USA: Scrivener Publishing LLC, 2011

Utracki L A. Characterization of high temperature polymer blends for specific applications: fuel cells and aerospace applications. In: DeMeuse M T, ed. High Temperature Polymer Blends. Cambridge: Woodhead Publishing Limited, 2014, 70–129

Aidani R E, Nguyen-Tri P, Malajati Y, et al. Photochemical aging of an e-PTFE/NOMEX® membrane used in firefighter protective clothing. Polymer Degradation and Stability, 2013, 98(7): 1300–1310

Akatsuka M, Takezawa Y. Study of high thermal conductive epoxy resins containing controlled high-order structures. Journal of Applied Polymer Science, 2003, 89(9): 2464–2467

Yu C, Zhang J, Li Z, et al. Enhanced through-plane thermal conductivity of boron nitride/epoxy composites. Composites Part A: Applied Science and Manufacturing, 2017, 98: 25–31

Kim G H, Lee D, Shanker A, et al. High thermal conductivity in amorphous polymer blends by engineered interchain interactions. Nature Materials, 2015, 14(3): 295–300

Zhou W. Thermal and dielectric properties of the AlN particles reinforced linear low-density polyethylene composites. Thermochimica Acta, 2011, 512(1–2): 183–188

Chen J, Huang X, Sun B, et al. Vertically aligned and interconnected boron nitride nanosheets for advanced flexible nanocomposite thermal interface materials. ACS Applied Materials & Interfaces, 2017, 9(36): 30909–30917

Jiang Y, Liu Y, Min P, et al. BN@PPS core–shell structure particles and their 3D segregated architecture composites with high thermal conductivities. Composites Science and Technology, 2017, 144: 63–69

Fu J F, Shi L Y, Zhong Q D, et al. Thermally conductive and electrically insulative nanocomposites based on hyperbranched epoxy and nano-Al2O3 particles modified epoxy resin. Polymers for Advanced Technologies, 2011, 22(6): 1032–1041

Shi Z, Fu R, Agathopoulos S, et al. Thermal conductivity and fire resistance of epoxy molding compounds filled with Si3N4 and Al(OH)3. Materials & Design, 2012, 34: 820–824

Song W L, Veca L M, Kong C Y, et al. Polymeric nanocomposites with graphene sheets––Materials and device for superior thermal transport properties. Polymer, 2012, 53(18): 3910–3916

Ding P, Su S, Song N, et al. Highly thermal conductive composites with polyamide-6 covalently––grafted graphene by an in situ polymerization and thermal reduction process. Carbon, 2014, 66 (3): 576–584

Bozlar M, He D, Bai J, et al. Carbon nanotube microarchitectures for enhanced thermal conduction at ultralow mass fraction in polymer composites. Advanced Materials, 2010, 22(14): 1654–1658

Yu S, Lee J W, Han T H, et al. Copper shell networks in polymer composites for efficient thermal conduction. ACS Applied Materials & Interfaces, 2013, 5(22): 11618–11622

Zhou W, Zuo J, Ren W. Thermal conductivity and dielectric properties of Al/PVDF composites. Composites Part A: Applied Science and Manufacturing, 2012, 43(4): 658–664

Wu X, Yang Z, Kuang W, et al. Coating polyrhodanine onto boron nitride nanosheets for thermally conductive elastomer composites. Composites Part A: Applied Science and Manufacturing, 2017, 94: 77–85

Kong K T S, Mariatti M, Rashid A A, et al. Enhanced conductivity behavior of polydimethylsiloxane (PDMS) hybrid composites containing exfoliated graphite nanoplatelets and carbon nanotubes. Composites Part B: Engineering, 2014, 58(3): 457–462

Li Z, Wang D, Zhang M, et al. Enhancement of the thermal conductivity of polymer composites with Ag–graphene hybrids as fillers. physica status solidi (a), 2014, 211(9): 2142–2149

Yuan W, Xiao Q, Li L, et al. Thermal conductivity of epoxy adhesive enhanced by hybrid graphene oxide/AlN particles. Applied Thermal Engineering, 2016, 106: 1067–1074

Chen J, Huang X, Zhu Y, et al. Cellulose nanofiber supported 3D interconnected BN nanosheets for epoxy nanocomposites with ultrahigh thermal management capability. Advanced Functional Materials, 2017, 27(5): 1604754

Dai W, Yu J, Liu Z, et al. Enhanced thermal conductivity and retained electrical insulation for polyimide composites with SiC nanowires grown on graphene hybrid fillers. Composites Part A: Applied Science and Manufacturing, 2015, 76: 73–81

Zhou W, Gong Y, Tu L, et al. Dielectric properties and thermal conductivity of core–shell structured Ni@NiO/poly(vinylidene fluoride) composites. Journal of Alloys and Compounds, 2017, 693: 1–8

Cui Z, Oyer A J, Glover A J, et al. Large scale thermal exfoliation and functionalization of boron nitride. Small, 2014, 10(12): 2352–2355

Tsai M H, Tseng I H, Chiang J C, et al. Flexible polyimide films hybrid with functionalized boron nitride and graphene oxide simultaneously to improve thermal conduction and dimensional stability. ACS Applied Materials & Interfaces, 2014, 6(11): 8639–8645

Fang H, Bai S L, Wong C P. Thermal, mechanical and dielectric properties of flexible BN foam and BN nanosheets reinforced polymer composites for electronic packaging application. Composites Part A: Applied Science and Manufacturing, 2017, 100: 71–80

Muratov D S, Kuznetsov D V, Il’Inykh I A, et al. Thermal conductivity of polypropylene composites filled with silanemodified hexagonal BN. Composites Science and Technology, 2015, 111: 40–43

Mittal G, Rhee K Y, Park S J. Processing and characterization of PMMA/PI composites reinforced with surface functionalized hexagonal boron nitride. Applied Surface Science, 2016, 415 (SI): 49–54

Goldin N, Dodiuk H, Lewitus D. Enhanced thermal conductivity of photopolymerizable composites using surface modified hexagonal boron nitride fillers. Composites Science and Technology, 2017, 152: 36–45

Kim K, Kim M, Kim J. Thermal and mechanical properties of epoxy composites with a binary particle filler system consisting of aggregated and whisker type boron nitride particles. Composites Science and Technology, 2014, 103(103): 72–77

Gu J, Yang X, Lv Z, et al. Functionalized graphite nanoplatelets/ epoxy resin nanocomposites with high thermal conductivity. International Journal of Heat and Mass Transfer, 2016, 92: 15–22

Huang M W, Cheng Y W, Pan K Y, et al. The preparation and cathodoluminescence of ZnS nanowires grown by chemical vapor deposition. Applied Surface Science, 2012, 261(8): 665–670

Jang I, Shin K H, Yang I, et al. Enhancement of thermal conductivity of BN/epoxy composite through surface modification with silane coupling agents. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2017, 518: 64–72

Pan C, Kou K, Jia Q, et al. Improved thermal conductivity and dielectric properties of hBN/PTFE composites via surface treatment by silane coupling agent. Composites Part B: Engineering, 2017, 111: 83–90

Zhang S, Li X, Guan X, et al. Synthesis of pyridine-containing diamine and properties of its polyimides and polyimide/hexagonal boron nitride composite films. Composites Science and Technology, 2017, 152: 165–172

Yang X, Tang L, Guo Y, et al. Improvement of thermal conductivities for PPS dielectric nanocomposites via incorporating NH2-POSS functionalized nBN fillers. Composites Part A: Applied Science and Manufacturing, 2017, 101: 237–242

Yu J, Huang X, Wu C, et al. Interfacial modification of boron nitride nanoplatelets for epoxy composites with improved thermal properties. Polymer, 2012, 53(2): 471–480

Kim K, Ju H, Kim J. Surface modification of BN/Fe3O4 hybrid particle to enhance interfacial affinity for high thermal conductive material. Polymer, 2016, 91: 74–80

Gu J, Dong W, Tang Y, et al. Ultralow dielectric fluoridecontaining cyanate ester resins combining with prominent mechanical properties and excellent thermal & dimension stabilities. Journal of Materials Chemistry C: Materials for Optical and Electronic Devices, 2017, 5(28): 6929–6936

Gong Y, Zhou W, Kou Y, et al. Heat conductive h-BN/CTPB/ epoxy with enhanced dielectric properties for potential highvoltage applications. High Voltage, 2017, 2(3): 172–178

Huang X, Iizuka T, Jiang P, et al. Role of interface on the thermal conductivity of highly filled dielectric epoxy/AlN composites. The Journal of Physical Chemistry C, 2012, 116(25): 13629–13639

Chen H, Ginzburg V V, Yang J, et al. Thermal conductivity of polymer-based composites: Fundamentals and applications. Progress in Polymer Science, 2016, 59: 41–85

Burger N, Laachachi A, Ferriol M, et al. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Progress in Polymer Science, 2016, 61: 1–28

Acknowledgements

This research was financially supported by the Natural Science Foundation of Shanghai (Grant No. 17ZR1401100) and the National Natural Science Foundation of China (Grant No. 51473031).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duan, G., Wang, Y., Yu, J. et al. Improved thermal conductivity and dielectric properties of flexible PMIA composites with modified micro- and nano-sized hexagonal boron nitride. Front. Mater. Sci. 13, 64–76 (2019). https://doi.org/10.1007/s11706-019-0446-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11706-019-0446-3