Abstract

The Lamb–Mössbauer factor is a crucial material parameter for the proper quantitative analysis of Mössbauer experiments. We report on a method for determining the Lamb–Mössbauer factor of powdered samples. It utilizes a resonant Mössbauer spectrometer together with a customized sample preparation, which ensures a homogeneous thickness of the powdered absorbers. Compared with other methods of Lamb‒Mössbauer factor determination, the presented approach is direct and requires only a single Mössbauer measurement. To demonstrate this method, the Lamb–Mössbauer factor of iron(II) oxalate dihydrate samples with varying thickness was measured. The resulting value of the Lamb–Mössbauer factor was 0.38 ± 0.03. The presented approach can be used for a large variety of powdered materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Lamb–Mössbauer factor describes the probability of the recoilless interaction of resonant photons with Mössbauer nuclei. It depends on the atomic bonds within the crystal structure, and it is closely related to the phonon spectrum. The Lamb–Mössbauer factor can generally exhibit temperature dependence and anisotropy. The knowledge of its value is essential for the correct evaluation of Mössbauer experiments and their interpretation. The Mössbauer spectroscopy experimental results provide the relative areas of the individual spectral components. However, to extract the quantitative information on the phase composition, the corresponding Lamb–Mössbauer factor values have to be known (Sawatzky et al. 1969).

There is a number of different experimental approaches for the Lamb–Mössbauer factor determination (Sorescu 2002; Guérault et al. 2001; Pollak and Karfunkel 1993). A frequently used method is a comparison with known standards (Szymański et al. 2010; Sorescu 2011; Barrero et al. 2013; Rusanov et al. 2006; Spina and Lantieri 2014), where the disadvantage lies in the indirectness of this method. Alternatively, the option is to measure the studied material at different temperatures (Sturhahn and Chumakov 1999), but this method is very time-consuming and expensive. Another method is based on the evaluation of the linewidth or spectral area dependence on a sample thickness (Decker and Lortz 1971). In our previous work, we have introduced an approach based on the application of the resonant Mössbauer spectrometer [i.e., Mössbauer spectrometer utilizing the resonant detector in the configuration (Procházka et al. 2022)], which was successfully tested for the alpha-iron foil (Procházka et al. 2022). This resonant detector-based method requires only a single experiment to directly determine the Lamb–Mössbauer factor of the studied material.

In this article, we present the application of the method specifically for measurements of powdered materials. In the case of a powder sample, it is necessary to prepare a homogeneous layer of the sample in the studied area. Additionally, it is necessary to know the composition and density of the studied material. The applicability of the resonant detector-based Lamb–Mössbauer factor determination for the case of powder samples is demonstrated on iron(II) oxalate dihydrate powder. The procedure to ensure the above-mentioned conditions and subsequently to determine the Lamb–Mössbauer factor is presented in detail. The article is organized as follows: first, the theoretical approach needed for the evaluation of the experiments is presented. Next, the sample preparation, which is crucial for the method, and the used equipment are described, the demonstrating material is characterized and the measured Mössbauer spectra are presented. Finally, the Lamb–Mössbauer factor value is determined.

Theoretical

The applied method allows to determine the Lamb–Mössbauer factor due to the possibility to separate the background in the resonant Mössbauer spectrum. That is done by properly synchronizing the Doppler velocity (energy) modulation of the source and of the resonant detector. Thus, we can isolate and extract the background contribution from the spectrum and evaluate the nuclear resonant absorption only. In the following, we express a mathematical formula for a resonant Mössbauer spectrum of iron(II) oxalate dihydrate, which was selected for the demonstration of the method. This material exhibits zero magnetic splitting, quadrupole splitting of 1.72 mm/s and isomer shift of 1.19 mm/s, resulting in a doublet (Kopp et al. 2019). The transmission Mössbauer spectrum measured using a resonant detector (Odeurs et al. 2000, 2002) can be expressed by the full transmission integral approach (Procházka et al. 2022). The resonant Mössbauer spectrum including the background and instrumental broadening can be described by formula:

where Br is the background, and gv (\({E}_{\mathrm{s}}^{^{\prime}}\), Es, σv) is a Gaussian approximation of instrumental line-broadening (Procházka et al. 2022) with the mean energy Es and standard deviation σv. The function \({M}_{\mathrm{r}}\left({E}_{\mathrm{s}}^{^{\prime}}\right)\) is given by formula:

where Nd is the scaling parameter, µe is the electronic absorption coefficient, d is the absorber thickness and Γ is the natural linewidth. The complex function Pr(E) describes the Mössbauer doublet energy dependence and is given as:

The weight coefficients W1 and W2 are both equal to 0.5. Formula (3) accounts for the inhomogeneous broadening, which is approximated by the Gaussian distribution functions ga (E′aj, Eaj, σ). Parameters Γs and Γd are the linewidth of the source and resonant detector. The (de)synchronizing of the source line and the resonant detector line depends on the difference between \({E}_{\mathrm{s}}{^{\prime}}\) and Ed. The effective thickness deff of the absorber is given as:

where σ0 is the nuclear resonant differential cross-section, η is the number density of Mössbauer nuclei and f is the Lamb–Mössbauer factor. Within this work, we used the values of 2.464 · 106 barn/atom for σ0 (Röhlsberger 2004) and 1.639 · 1013 1/cm3 for η. To ensure the correct data evaluation, the corrections for the nonresonant absorption contribution and the nonlinear baseline were conducted as well [see Procházka et al. (2022) for more information].

Experimental

Materials

Chemicals

The iron(II) oxalate dihydrate powder (99%, Sigma-Aldrich) with summation formula FeC2O4·2H2O was used for all measurements.

Sample preparation

The presented Lamb–Mössbauer factor determination method assumes that the studied powdered material is in the form of a homogeneous layer. This can be achieved by dispersing the appropriate amount of the studied powder in a liquid and letting it sediment. The inhomogeneities in the thickness of such a layer should not exceed the size of grains. Any liquid can be used as long as it does not dissolve the material under study. In our study, iron(II) oxalate dihydrate samples of varying mass were dispersed in deionized water and left to sediment on the filtration paper. Next, the supernatant liquid was removed using vacuum, and samples were left to dry (see Fig. 1).

Methods

X-ray powder diffraction

X-ray diffraction pattern of iron(II) oxalate was acquired with D8 ADVANCE diffractometer (BRUKER, Bremen, Germany) over 2θ range of 10°‒100° with the scan step of 0.02°. The diffractometer operated in Bragg–Brentano parafocusing geometry and was equipped with LYNXEYE position sensitive detector and X-ray tube with cobalt anode as the source of Co Kα radiation.

The 0.6-mm divergence slit and 2.5° axial Soller slits were inserted into the primary beam path, whereas Fe Kβ filter, and 2.5° axial Soller slits were implemented to the secondary beam path. The Rietveld analysis was conducted using MAUD program (Lutterotti 2010).

Mössbauer spectroscopy

For the Mössbauer spectra acquisition, the OLTWINS Mössbauer spectrometer setup was used (Stejskal et al. 2023). It is designed for experiments in an arrangement where both a radioactive source and the resonant detector can be moved independently using a pair of robust velocity units (Novák et al. 2022). A motion control procedure was used to achieve an overlap between the emission line of the radioactive source and the detection line of the resonant detector. For more detailed information on the applied measurement procedure, see Procházka et al. (2022). Velocity axes of all Mössbauer experiments were calibrated using α-iron reference sample. 57Co embedded in rhodium matrix was used as the radiation source.

Results and discussion

The Rietveld refinement of the XRD pattern (see Fig. 2a) confirmed the material purity. The observed imperfections of the fit are caused by a relatively complicated structure in which the oxalate chains are prone to various stacking faults that are difficult to model. Nonetheless, all diffraction lines could be ascribed to α-FeC2O4·2H2O with monoclinic structure (space group C2/c). The model of α-FeC2O4·2H2O unit cell is shown in Fig. 2b. Rietveld analysis provided the material lattice parameters, i.e., a = 12.02 Å, b = 5.56 Å, c = 9.92 Å and β = 128.5°. The obtained values were used for determining the volume of the unit cell Vc. Subsequently, the material density ρ was obtained using the formula (5):

where Z is the number of molecules per unit cell (Z = 4), Mm is the molar mass and NA is Avogadro constant. The density of the material was determined as ρ = 2.30 g/cm3. Knowing the mass of iron oxalate powder and the diameter of the prepared specimen (25 mm), the density was used to find the thickness of the iron oxalate layer for individual samples. The specimen thicknesses were in the range from 0.05 to 1 mm.

The resonant Mössbauer spectra were acquired with the relative velocity of the source and absorber in the range of ± 8 mm/s. The obtained spectra after normalization (simultaneously a bent of the baseline was corrected by a polynomial function, with the correction having no effect to the final result) are presented in Fig. 3. For details on the operation of the resonant Mössbauer spectrometer, see (Procházka et al. 2022). It can be observed that the absorption at the positions of the spectral lines increased with the increasing specimen thickness.

The absorption of gamma photons at the resonant frequencies (i.e., minimum of the absorption lines) is plotted with respect to the specimen thickness in Fig. 4 (green). It can be seen that the dependence follows the exponential absorption law as could be expected. Additionally, the electronic absorption was used to confirm the validity of determining the specimen thickness. The electronic absorption was derived from the difference between the baseline and the background measured with and without the sample (Procházka et al. 2022), see Fig. 4 (orange). The value of electronic absorption coefficient was determined by fitting the data with the exponential absorption law as μe = (52 ± 5) 1/cm. This value is in agreement with the linear absorption coefficient determined from a nominal sample composition and the individual linear absorption coefficients (NIST 2022), i.e., μe = 58.2 1/cm. The agreement of these two values confirmed that the preparation of the sample layers was successful, and the layers exhibited the expected thickness.

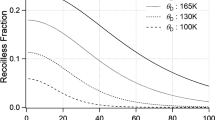

The Lamb–Mössbauer factor was determined by fitting the obtained spectra of individual specimen using the model described in the theoretical section. The representative fitted Mössbauer spectrum is shown in Fig. 5. There are five regions (I, II, III, IV and V), that can be identified in the shown spectrum. In regions I and V, the source line and the resonant detector line were not in an overlap and the detector registered only the “non-recoilless” background. Regions II and IV represent transition phases where the source and detector lines were overlapping only partially. The shape of these transition regions of the spectrum is given by the line shape of the conversion material in the resonant detector. Lastly, in region III, the source and detector lines are in full overlap. Again, for a detailed description of the resonant Mössbauer spectrometer functioning, the readers are referred to (Procházka et al. 2022). Only the data in region III (nuclear absorption in the sample and baseline) and regions I and V (background) were fitted. The transition regions were omitted from the fitting process as they contain no information that is needed for the Lamb–Mössbauer factor determination. All the obtained values of the Lamb–Mössbauer factor for individual specimen are shown in Fig. 6. We can see a distribution of the obtained values around the average. Larger deviation and uncertainty of several data points are the result of a lower statistics of the individual experiments. However, the obtained results clearly show the applicability of the presented approach for the determination of the Lamb–Mössbauer factor. Although a single measurement is sufficient for the Lamb–Mössbauer factor determination, to increase the precision we averaged all the obtained values and the resulting value of the Lamb–Mössbauer factor for iron(II) dihydrate was found as f = 0.38 ± 0.03.

Conclusions

In this work, the experimental approach for determining the Lamb–Mössbauer factor of powdered materials was presented. The method is based on the utilization of the Mössbauer resonant detector. The approach and its advantages (directness, simplicity and time-efficiency) were demonstrated by determining the Lamb–Mössbauer factor of iron(II) oxalate dihydrate. The resulting value f = 0.38 ± 0.03 was determined. This approach requires the studied sample to be spread into a homogeneous layer, which is ensured by dispersing the sample in a liquid and letting it sediment. The advantage of this method lies mainly in its simplicity where only a single transmission measurement is required. The resonant Mössbauer spectrometer can also be easily utilized in combination with a cryostat, thus allowing an investigation of a temperature dependence of the Lamb–Mössbauer factor as well. The presented procedure should be easily applicable to any powdered material.

References

Barrero CA, García KE, Coa JC (2013) Simultaneous determination of the two recoilless F-fractions of akaganeite using a single Mössbauer spectrum. J Phys Chem Solids 74(7):1012–1016. https://doi.org/10.1016/j.jpcs.2013.02.025

Decker DL, Lortz LE (1971) Lamb–Mössbauer factor of sodium ferrocyanide. J Appl Phys 42(2):830–833. https://doi.org/10.1063/1.1660100

Guérault H, Labaye Y, Grenèche JM (2001) Recoilless factors in nanostructured iron-based powders. Hyperfine Interact 136–137(1–2):57–63. https://doi.org/10.1023/A:1015541027765

Kopp J, Novak P, Kaslik J, Pechousek J (2019) Preparation of magnetite by thermally induced decomposition of ferrous oxalate dihydrate in the combined atmosphere. Acta Chim Slov 66:455–465. https://doi.org/10.17344/acsi.2019.4933

Lutterotti L (2010) Total pattern fitting for the combined size-strain-stress-texture determination in thin film diffraction. Nucl Instrum Methods Phys Res Sect B 268(3–4):334–340. https://doi.org/10.1016/j.nimb.2009.09.053

NIST (2022) NIST 2022 https://www.Nist.Gov/Pml/x-Ray-Mass-Attenuation-Coefficients

Novák P, Procházka V, Stejskal A (2022) Universal drive unit for detector velocity modulation in mössbauer spectroscopy. Nucl Instrum Methods Phys Res Sect A Accel Spectrom Detect Assoc Equip 1031:166573. https://doi.org/10.1016/j.nima.2022.166573

Odeurs J, Hoy GR, L’abbé C, Shakhmuratov RN, Coussement R (2000) Quantum-mechanical theory of enhanced resolution in Mössbauer spectroscopy using a resonant detector. Phys Rev B Condens Matter Mater Phys 62(10):6148–6157. https://doi.org/10.1103/PhysRevB.62.6148

Odeurs J, Hoy GR, L’abbé C, Koops GEJ, Pattyn H, Shakhmuratov RN, Coussement R, Chiodini N, Paleari A (2002) Resonant-detector Mössbauer spectroscopic studies of Sn doped SiO2 analysed using quantum mechanical theory. Hyperfine Interact 139–140(1–4):685–690. https://doi.org/10.1023/A:1021255702829

Pollak H, Karfunkel U (1993) Iron recoil-free fraction ratios in minerals with application to crocidolite. Hyperfine Interact 77(1):235–254. https://doi.org/10.1007/BF02320315

Procházka V, Novák P, Stejskal A, Dudka M, Vrba V (2022) Lamb-Mössbauer factor determination by resonant Mössbauer spectrometer. Phys Lett Sect A Gen Atom Solid State Phys 442:128195. https://doi.org/10.1016/j.physleta.2022.128195

Röhlsberger R (2004) Nuclear condensed matter physics using synchrotron radiation. https://doi.org/10.1007/b86125

Rusanov V, Stankov S, Gushterov V, Tsankov L, Trautwein AX (2006) Determination of Lamb–Mössbauer factors and lattice dynamics in some nitroprusside single crystals. Hyperfine Interact 169(1–3):1279–1283. https://doi.org/10.1007/s10751-006-9437-8

Sawatzky GA, Van Der Woude F, Morrish AH (1969) Recoilless-fraction ratios for Fe57 in octahedral and tetrahedral sites of a spinel and a garnet. Phys Rev 183(2):383–386. https://doi.org/10.1103/PhysRev.183.383

Sorescu M (2002) Evolution of the Mössbauer recoilless fraction during mechanochemical activation of iron oxides. J Mater Sci Lett 21(22):1759–1761. https://doi.org/10.1023/A:1020916719859

Sorescu M (2011) Recoilless fraction of cobalt-doped magnetite. Nucl Instrum Methods Phys Res Sect B 269(6):590–596. https://doi.org/10.1016/j.nimb.2011.01.013

Spina G, Lantieri M (2014) A straightforward experimental method to evaluate the Lamb–Mössbauer factor of a 57Co/Rh source. Nucl Instrum Methods Phys Res Sect B Beam Interact Mater Atoms 318(PART B):253–257. https://doi.org/10.1016/j.nimb.2013.10.002

Stejskal A, Procházka V, Dudka M, Vrba V, Kočiščák J, Novák P (2023) A dual Mössbauer spectrometer for material research, gamma optics with and coincidence experiments. J Int Meas Conf 215:112850. https://doi.org/10.1016/j.measurement.2023.112850

Sturhahn W, Chumakov A (1999) Lamb–Mössbauer factor and second-order Doppler shift from inelastic nuclear resonant absorption. Hyperfine Interact 123–124(1–4):809–824. https://doi.org/10.1023/A:1017060931911

Szymański K, Dobrzyński L, Satuła D, Olszewski W (2010) Recoilless fraction determination by internal standard. Nucl Instrum Methods Phys Res Sect B 268(17–18):2815–2819. https://doi.org/10.1016/j.nimb.2010.06.009

Acknowledgements

Authors thank to internal IGA grant of Palacký University (IGA_PrF_2022_003).

Funding

Open access publishing supported by the National Technical Library in Prague.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Novák, P., Schlattauerová, T., Procházka, V. et al. Lamb–Mössbauer factor of powders determined by Mössbauer spectroscopy with resonant detector. Chem. Pap. 77, 7283–7288 (2023). https://doi.org/10.1007/s11696-023-02844-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-023-02844-x