Abstract

Oxidation of water or wastewaters with classical oxidants such as chloramine, chlorine dioxide, ozone or permanganate may lead to formation of carcinogenic N-nitrosodimethylamine (NDMA), when dimethylamine (DMA) is present as water pollution. This study shows that peroxydisulfate (PDS) could be considered as relatively ‘safe’ oxidant as PDS partly destroys dimethylamine without formation of NDMA. Prior to use, peroxydisulfate was activated. Metal ions Fe+2, UV radiation and metal oxides CuO were compared as activator compounds to understand their efficiency in PDS systems (radical and non-radical) for oxidation of DMA. The amount of nitrate formed as the result of nitrogen oxidation, as well as formaldehyde (FA), formed as the result of methyl groups oxidation, was monitored as an indicator of DMA degradation. Application studies conducted on natural water showed that activated peroxydisulfate can effectively protect against the undesirable NDMA formation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water treatment plants supported by highly treated municipal wastewater effluents are increasingly considered as a local supply of potable water. Increases in the demand for the reuse of wastewater, due to the shortage of fresh water resources in an arid area, require high-quality effluent from wastewater treatment plants.

In the last two decades, intensive research has been undertaken to find effective methods for removing toxic impurities that occur in water, sewage and leachate in both trace amounts and in relatively high concentrations. Conventional methods for wastewater treatment are not always effective and efficient, especially when removing difficult-biodegradable substances. These substances include: pesticides, phenols and their derivatives, halogenated compounds, aliphatic and aromatic hydrocarbons, surface active substances, and organic dyes. The afore-mentioned compounds, as well as the derivatives of their incomplete oxidation, present at low concentrations in discharged treated wastewater, can negatively affect the color, the taste, and the smell of water, and pose serious threats to living organisms.

Due to increasingly restrictive legal regulations, wastewater from various industries, e.g. tanneries, must be specially treated. Such wastewater is a more difficult medium for treatment than, for example, municipal wastewater. Tannery wastewater (TW) consists of a complex matrix, where both high levels of inorganic and organic harmful compounds is detected (Schrank et al. 2005; Vilardi et al. 2018a). Besides Cr (VI), various toxic organic compounds, such as phenols, 1,1-dimethylethyl-2-phenylethiazole, methyl-thio-benzo-thiazole, p-Cresol and inorganic anions have been commonly found in TW (Reemtsma et al. 1999; Chandra et al. 2011). The high concentration of reducing compounds in TW causes the noticeable Chemical Oxygen Demand (COD, 3–10 g/L) and Biochemical Oxygen Demand (BOD, 0.5–4 g/L), that usually characterizes the TW streams, besides the strong odor and dark brown color (Wang et al. 2014; Deghles and Kurt 2016). TW also deals with very high concentrations of inorganic salts, such as chlorides, sulfates and nitrates (500–5000 mg/L) (Liu et al. 2017). Conventional physicochemical purification processes (Song et al. 2004; Chowdhury et al. 2013), chemical (Naumczyk and Rusiniak 2005; Rameshraja and Suresh 2011), as well as biological ones (Durai and Rajasimman 2011), in the case of tannery wastewater are usually insufficient.

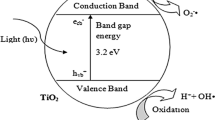

AOPs (advanced oxidation processes) purification methods are an alternative to these conventional purification methods, including the Fenton’s reaction (Mandal et al. 2010), which use the high oxidation potential of generated hydroxyl radicals at the level of 2.8 V (Schrank et al. 2005; Rameshraja and Suresh 2011; Abdel-Aal et al. 2015). Fenton’s oxidation is one of the most effective methods for removing impurities from wastewater. Moreover, the advantage of the Fenton’s reaction is that, apart from the oxidation processes, the coagulation of impurities also occurs (Xing et al. 2006). Recent work of Przywara (2017) discussed the research aimed at determining the effectiveness of tannery wastewater treatment in the process of in-depth oxidation using Fenton's reagent. The process was carried out using different doses of iron varied in the range of 0.056 g Fe2+/L to 0.56 g Fe2+/L, H2O2 from 0.34 to 5.44 g/L, and in the pH range from 2.5 to 3.5.

Extensive research on the treatment of tannery wastewater and the use of AOP is conducted by Giorgio Vilardi et al. (2018a, b, 2019; Vilardi 2018 ). Vilardi in his study reports a comparison among conventional Fenton oxidation (CF) and heterogeneous Fenton oxidation (HF) processes performed at large lab-scale on a Tannery Wastewater (TW). The heterogeneous Fenton process was carried out by using self-lab-prepared iron nanoparticles as a solid catalyst. Two different catalyst/oxidant (Cat/Ox) (w/w) ratio were examined. A study on the influence of pH on the process efficiency, monitoring the COD, TP, H2O2 and Cr(VI) variation over the reaction time was carried out.

Among AOPs, Fenton processes are well-known within the scientific community because of their suitability to remove no-biodegradable organic compounds in complex wastewaters, such as those from olive oil (Hodaifa et al. 2013) and pulp & paper industries (Tambosi et al. 2006). The main advantages of conventional Fenton (CF) process involve mild operative conditions (the process is usually performed at room temperature and atmospheric pressure) as well as low-cost and easily available reagents, (Kang and Hwang 2000). On the contrary, the process is often limited by some important drawbacks, such as the necessity to operate at acid conditions (pH = 2.5–3.5), a large hydrogen peroxide dosage and iron sludge production (Babuponnusami and Muthukumar 2014).

The use of solid iron based catalysts in an heterogeneous Fenton (HF) process (e.g., magnetite or nano Zero-Valent Iron particles, nZVI), instead of iron soluble salts, has been already proved to reduce overall sludge production (Kuang et al. 2013; Yang et al. 2015). In particular, nZVI is a well-known suitable material for the treatment of Cr-polluted wastewaters (Vilardi et al. 2018a), because of its peculiar characteristics, such as noticeable specific surface area and chemical activity, towards both inorganic (Fu et al. 2014) and organic pollutants (Gosu et al. 2016).

Nitrate removal from urban wastewater (Stoller et al. 2015) and from contaminated groundwater represented a severe environmental issue (De Filippis et al. 2013). Various technologies applied also in more complex liquid matrix (Ochando-Pulido et al. 2014), such as membrane processes (Ochando-Pulido and Stoller 2015), AOPs (De Filippis et al. 2011), photo catalysis (Stoller et al. 2015), or a combination of these processes (Vuppala et al. 2017), which have been successfully used to treat organic (Bavasso et al. 2016) and nitrogen polluted wastewaters (Di Palma et al. 2018; Vilardi 2018).

Novel technologies to meet stringent water quality standards include advanced oxidation processes (Park et al. 2016; Chuang and Mitch 2017). Oxidation of water/wastewaters containing dimethylamines (DMA) with classical oxidants such as chloramine, chlorine dioxide, ozone or permanganate can lead to formation of N-nitrosodimethylamine (NDMA), compound highly undesirable in potable water due to carcinogenic effects (Mitch and Sedlak 2002; Choi and Valentine 2002; Andrzejewski et al. 2007, 2008). The reaction of oxidation can contribute to total mineralization of the amine or it can be terminated when intermediates are formed. Formic acid, formaldehyde and nitrate are typical by-products of DMA oxidation. The mechanism of NDMA formation is well described for chloramination case (Mitch and Sedlak 2002; Choi and Valentine 2002), but the mechanism of nitrosamine creation upon ozonation process is still a matter of discussion (Lee et al. 2007; Oya et al. 2008; Yang et al. 2009; Andrzejewski et al. 2012).

Peroxydisulfate (PDS), also known as persulfate, is lately often considered as a very useful oxidant. However, this compound to be an effective oxidant must be activated. Several types of activators are used, but application of metal ions e.g. Fe+2, oxides of metals such as CuO or UV radiation seems to be the most promising (Berlin 1986; Anipsitakis and Dionysiou 2003, 2004; Zhang et al. 2014). PDS activation with metal ions leads to the formation of very reactive sulfate radicals (SO4*−) according to Eq. 1 (Anipsitakis and Dionysiou 2004):

Activation of PDS with UV radiation also leads to the formation of reactive sulfate radicals (SO4*–) according to Eq. 2 (Berlin 1986):

UV radiation activation can be two times more effective comparing to Fe+2 activation: two SO4*– radicals versus one radical, respectively. However, the efficiency of UV radiation activation is limited by low water transparency (turbidity). The radicals significantly increase micropollutants destruction efficiency. On the other hand, two drawbacks of the activation methods described above should be mentioned. First, for Fe+2 activation only 50% of PDS is converted to sulfate radicals (see Eq. 1). Secondly, sulfate radicals can be scavenged with chloride. Chloride is present in all raw waters and wastewaters at millimols per liter. The reaction can lead to formation of chlorine radical Cl* which further forms undesired chlorinated products. Similarly, bromide also scavenges sulfate radicals leading to formation of brominated derivatives (Zhang et al. 2014). Brominated products are considered as more hazardous to environment than their chlorinated analogues. PDS activation with copper oxide seems to be controversial as according to some authors CuO does not lead to radical formation (Zhang and Andrew 2013; Zhang et al. 2014), while others report formation of sulfate radicals as main oxidation species (Hu et al. 2017). The process is efficient and it is not sensitive to chloride presence (Zhang et al. 2014; Hu et al. 2017). According to Du et al. (2017) and Hu et al. (2017) sulfate radicals were mainly responsible for degradation of iodinated X-ray contrast agent iopamidol in CuO/PDS system. Zhang and Andrews (2013) have proved the catalytically enhanced formation of NDMA from DMA in chloraminated water in the presence of CuO as a copper corrosion product.

There is no information in literature concerning the reaction of persulfate with aliphatic amines in aqueous solutions. Application of PDS gives a unique chance to check an efficiency of PDS systems (radical and non-radical) for oxidation of DMA. Therefore, it is possible to tailor oxidation mechanism of PDS simply by selecting the activation method.

The main objective of this paper is to study the ability of the PDS-based oxidation methods for possible formation of N-nitrosodimethylamine. Nitrate, formed as the result of nitrogen oxidation, as well as formaldehyde, formed as the result of methyl groups oxidation, were monitored as an indicator of DMA degradation.

PDS concentration in water can be determined by means of derivatization technique prior to absorption measurement at 352 nm (Zhang and Andrews 2013). Authors of this paper decided to apply two indirect methods for searching changes of PDS concentration during oxidation process: determination of sulfate concentration (one of molecule of PDS finally generates two molecules of sulfate ions) and continuous measurement of red-ox potential in the reaction mixture.

Materials and methods

Standards, solvents and reagents

All chemicals used in this work were of analytical grade or better: dimethylamine (DMA) 60% solution in water (Fluka, Switzerland), potassium peroxydisulfate (Fluka 98%, Switzerland), copper(II) oxide (CuO) prepared by means of two hours copper (II) carbonate (CuCO3) (Fluka, Switzerland) calcination at temperature of 320 °C, with specific area of 51.7 m2/g and average pore size of 22.8 nm, iron (II) sulfate (FeSO4) (source of ferrous ions) was prepared from pure iron (> 95%, Fluka, Switzerland) as a result of metal iron (Fe) reaction with solution of sulfuric acid (> 95%, Fluka, Switzerland), pH adjustments i.e. sulfuric acid (H2SO4) (> 95%, Fluka, Switzerland) or sodium hydroxide (NaOH) (> 98%, Fluka, Switzerland) as diluted solutions, hexane (95% J.T.BAKER ULTRA RESI-ANALYZED, USA), analytical standard of formaldehyde and O-(2,3,4,5,6-Pentafluorobenzyl)hydroxylamine hydrochloride (PFBOA) reagent for derivatization process (of 98% purity) were from Sigma-Aldrich (USA). Sodium bicarbonate (NaHCO3) and sodium carbonate (Na2CO3) were obtained from Sigma-Aldrich, Germany and France. A primary multi-anion standard solution, produced by Fluka, Switzerland, (Cat. No. 89886, Lot1265008) was used for calibration.

Deionized water from a Milli-Q Gradient system (Millipore, USA) was used for the preparation of all mixtures. The resistivity of the deionized water was equal to 18.2 MΩ·cm (at 25 °C). We also used membrane filters with a pore size of 0.45 μm (LLG, USA). Natural water samples used in experiments are described in detail in the Sect. “NDMA formation”.

Instrumentation

NDMA was analyzed by means of HPLC-SHIMADZU Nexera-I, LC-20140C 3D, coupled with UV-DAD detector. The presence of NDMA in selected samples of post-reaction mixtures were confirmed with GC–MS technique by means of Hewlett-Packard 5890 gas chromatograph coupled with low resolution Hewlett-Packard 5971A mass selective detector (MSD).

The presence of nitrate, nitrite (the products of DMA oxidation) and sulfate ions (the product of PDS decomposition) in the reaction mixture was determined by means of ion chromatography (IC). The employed ion chromatography system was a LC-20 ADSP Shimadzu equipment with a CDD-10Avp conductometric detector, DGU-20A5R degasser, CTO-20AC oven column with a 25μL injection loop and Shodex SI 52 4E analytical column. The system was controlled by CBM-20A communication bus module with LabSolution software. During the analysis, the Continuous Anion Regeneration System—CARS (SeQuant, Sweden) was used. The eluent was composed of 1.0 mM NaHCO3 and 3.5 mM Na2CO3. The eluent flow rate was 0.8 mL/min. The column pressure and temperature were set up at 9.8 MPa and 45 °C, respectively. The suppressor was automatically regenerated by 20 mM H2SO4.

Formaldehyde was analyzed by gas chromatography using Fisons Series GC equipped with 63Ni electron capture detector (ECD). Rtx-5MS (Restek) fused silica capillary column (30 m, 0.25 mm i.d., 0.25 µm film) was employed for the analysis, and Rtx-1301 (Restek) fused silica capillary column (30 m, 0.32 mm i.d., 0.5 µm film) was used as a confirmation column. Helium and nitrogen were used as a carrier gas and a detector make-up gas, respectively. Analysis was performed with a temperature program from 80 to 240 °C at 7 °C/min, then raised to 290 °C at 20 °C/min. DataApex ClarityTM software was used for collecting and processing of chromatographic data.

The pH measurements were determined by a WTW pH-meter equipped with SenTix pH electrodes (MultiLine® Multi 3430 IDS).

Total organic carbon (TOC) in selected aqueous samples was measured by means of AURORA Model 1030 TOC Analyzer (I.O. Analytical) using the peroxydisulfate/100 °C wet oxidation method.

For the determination of Red-ox potential multifunction meter CX-505 was used, equipped with red-ox electrode Aqua Medic Red-Ox/ORP coupled with data acquisition system based on ASUS G74S computer.

UV-C lamp (low pressure, mercury lamp 254 nm, 9 W) was applied for UV radiation, as needed during the experiment.

Description of experiments

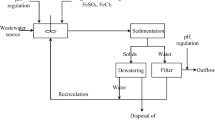

Peroxydisulfate has been applied in our experiments as a useful oxidant to destroy dimethylamine (DMA) without formation of N-nitrosodimethylamine (NDMA). For PDS to be an effective reagent, it should be activated. Deionized water was spiked with 0.22/mML dimethylamine DMA. All experiments were performed in a one liter glass reactor filled with 700 mL of reaction mixture that was continuously mixed with magnetic stirring of 700 rpm. Amounts of activators depended on the type of reagent. 81.8 mg of FeSO4 × 7H2O, 1:1 molar ratio of PDS/activator and 140 mg of CuO, 1:6.3 molar ratio of PDS/activator were applied, pH of the reaction was 5.8 as an optimal pH for destruction of selected contaminates with PDS/CuO process according to Zhang et al. (2014). The description of experiments and abbreviation of the corresponding experiment name are presented in Table 1.

All of experiments were carried out at ambient temperature for 60 min and were repeated 3 times for each activator.

Results and discussion

Formaldehyde formation as by-product of DMA oxidation

In general, when oxidants are in contact with water/wastewater containing dimethylamine, part of the DMA is oxidized to formaldehyde (FA) (Andrzejewski et al. 2011; Nawrocki and Andrzejewski 2011). Dimethylamine destruction during its oxidation by peroxydisulfate activated with ferrous ions, copper oxide or UV radiation was studied. It was observed that formaldehyde is evidently created as by-product when PDS is used. Results concerning formaldehyde formation as the result of DMA oxidation by ferrous ions, copper oxide and UV radiation activated PDS are shown in Fig. 1 (detailed description of experiments 1E, 2E, 3E see in Table 1). These results are presented as FA/DMA conversion rate [M/M %] versus reaction time. Because the activator itself can affect also DMA destruction, the effect of formaldehyde formation under the influence of activators themselves (without the presence of PDS) was additionally observed (detailed description of experiments 4E, 5E, 6E see in Table 1). The results are compared in Fig. 1. Presence of formaldehyde, as by-product of oxidation of methyl groups from DMA molecule, was observed in post-reaction mixtures independently on PDS activation mode. The conversion of DMA in formaldehyde proceeded vigorously, already during the first few minutes, and reached the value over 14% when ferrous ions were applied. In the case of the reaction of only iron ions, without PDS addition, the formation of formaldehyde did not occur.

The rapid increase in formaldehyde concentration was observed also during the first few minutes when CuO and UV radiation were applied as PDS activator. The concentration of FA slowly increased until the end of the process, the value of FA/DMA conversion rate was 8% and 12%, respectively. In the case of the reaction of DMA with only CuO activator, without of PDS addition, the maximum FA/DMA conversion rate exceeded 1.5%. It seems that CuO played dual role in this process: as a PDS activator and as an oxidant of DMA at the same time. A similar effect was observed when UV radiation was applied without of PDS addition. The conversion rate was more than 2%.

Nitrate as by-product of DMA oxidation

The results concerning presence of nitrate ions as by-products of DMA destruction by oxidation process using ferrous ions, copper oxide and UV radiation activated PDS are shown in Fig. 2 and compared with the effect of the activators themselves (without PDS). These results are presented as NO3−/DMA conversion rate [M/M %] versus reaction time.

The value of NO3−/DMA conversion rate using as indicator of DMA destruction strongly depended on an activation mode. Traces of nitrate were found into post-reaction mixtures of dimethylamine and peroxydisulfate activated by ferrous ions (Fe+2) and CuO. NO3−/DMA conversion rate was low and below 0.5%, whereas the reaction of DMA with UV radiation activated PDS resulted with considerable quantity of nitrate formed and NO3−/DMA conversion rate was over 15%.

Nitrate was also monitored during the reaction of DMA with ferrous ions and CuO without reagent PDS. In this case conversion rate of NO3−/DMA was very low (below 0.5%), and similar to that obtained for Fe+2 and CuO activated PDS. NO3−/DMA conversion rate was also low (below 2%) after reaction of DMA with UV radiation without reagent PDS. From this point of view, DMA oxidation by UV radiation activated PDS was the most effective process of DMA destruction. The presence of NO3− as DMA destruction product causes the fact that the former DMA molecule is unavailable as NDMA precursor, even if other oxidant, such as chloramine or ozone, are subsequently applied.

Determination of PDS destruction by sulfate ions formation and changes in red-ox potential

PDS destruction rate were evaluated by means of sulfate ions formation and red-ox potential changes. PDS destruction, measured as SO42−/PDS conversion rate [M/M%], obtained during DMA oxidation by ferrous ions, copper oxide and UV radiation activated PDS, are shown in Fig. 3. Sulfate ions formation yield and reaction dynamics strongly depend on PDS activation mode. PDS activation with ferrous ions results with very vigorous PDS destruction; the maximum, app. 92%, PDS destruction was obtained at the second minute of process. Unexpected phenomena were observed during CuO or UV radiation activation of PDS. Dynamics of PDS destruction processes during it activation by UV radiation and copper oxide was lower compared with ferrous ions activation: the maxima of conversions were obtained at 60th minute of reactions. Moreover, conversion rate obtained for CuO activated PDS was definitely lower and hardly exceed 20%. This phenomenon, observed for CuO activation, could be attributed to the fact that this is heterogenic activation process, which undergo at the border of two phases, i.e. solid (CuO suspension) and liquid (PDS solution in water).

PDS destruction rate, measured as changes in red-ox potential, obtained during DMA oxidation by ferrous ions, copper oxide and UV radiation activated PDS, is shown in Fig. 4. Some differences may be observed in changes of red-ox potentials depended on PDS activation modes. Very fast PDS decomposition resulted with vigorous red-ox potential increase up to the second minute, when Fe+2 activated PDS was used. Subsequently red-ox potential increased very slowly and reached 626 mV. Contrary to red-ox potential of Fe+2 activated PDS, red-ox potential of CuO or UV radiation activated PDS increased definitely slower and reached final potential 524 mV or 490 mV, respectively. It should be stressed that, despite to PDS degradation rate (see Fig. 3), red-ox potential of CuO activated PDS was similar to the one obtained for UV radiation activated PDS. Moreover, shapes of the curves corresponded with these obtained for the analysis of PDS degradation vs. activation mode (cf. Fig. 2).

An influence of activators, without PDS presence, on changes of red-ox potentials was also investigated. Relatively small increase of red-ox potentials vs. contact time, was observed in post-reaction mixtures containing individual activators. The higher increase of red-ox potentials did not exceed 60 mV.

NDMA formation

N-nitrosodimethylamine formation was investigated in both: deionized and natural spiked water. Natural water samples were collected in the rural area of Zielonka Forest Region, 25 km from the Adam Mickiewicz University, Campus Morasko, from natural pond in Boduszewo (see Fig. 5). The surface of the pond is 800 m2 and the maximum depth is 3.5 m. The self-sown plants grow along the coastline of the reservoir, the pond surface is well sunlit, not wooded and the banks gently sloping towards the water are stable. The water samples were collected from the near surface layer, at depths no greater than 0.5 m. The physico-chemical characteristics of natural water used in experiment are presented in Fig. 5.

Example of NDMA identification by HPLC-UV-DAD in post-reaction mixture of natural water spiked with dimethylamine and treated by activated peroxydisulfate is shown in Fig. 6.

No traces of NDMA for limit of detection LOD = 0.01 µg/L were found in post-reaction mixtures of dimethylamine and peroxydisulfate activated by activators, i.e. ferrous ions (Fe+2) and CuO or UV radiation. No UV radiation as activator was use in experiments with natural water from Boduszewo, because of high value of turbidity in water samples.

As demonstrated by research of natural water (TOC = 14 mg/L), dimethylamine oxidation by homogenic (Fe+2) and heterogenic (CuO) activated peroxydisulfate can effectively protect against the NDMA formation.

Conclusions

No NDMA was found in all post-reaction mixtures of DMA/PDS under experimental conditions. These results were different from these received for other commonly used oxidants like chloramine, ozone or chlorine dioxide, but similar to these obtained during DMA oxidation by H2O2. DMA was oxidized by H2O2 only in extremely high pH, i.e. equal to 11–12.

Nitrate, as by- product of DMA oxidation, was found in all post-reaction mixtures, independently on the type of an activator. Formaldehyde as by-product of DMA oxidation, was also detected. DMA destruction efficiency, measured as NO3−/DMA conversion rate [M/M%] strongly depended on PDS activation mode.

It seems that red-ox potential measurement could be considered as an auxiliary tool for the description of PDS oxidation process. Sulfuric ions determination could be considered as a good indicator of PDS destruction.

As demonstrated by research of natural water, oxidation of dimethylamine by activated peroxydisulfate can effectively protect against the NDMA formation.

Abbreviations

- AOPs:

-

Advanced oxidation processes

- BOD:

-

Biochemical oxygen demand

- CF:

-

Conventional Fenton oxidation

- COD:

-

Chemical oxygen demand

- DMA:

-

Dimethylamine

- ECD:

-

Electron capture detector

- FA:

-

Formaldehyde

- GC–MS:

-

Gas chromatography-mass detector

- HF:

-

Heterogeneous Fenton oxidation

- HPLC:

-

High-performance liquid chromatography

- MSD:

-

Mass selective detector

- NDMA:

-

N-Nitrosodimethylamine

- PDS:

-

Peroxydisulfate

- TOC:

-

Total organic carbon

- TW:

-

Tannery wastewater

- UV-DAD:

-

Ultraviolet- diode array detector

References

Abdel-Aal EA, Farghaly FE, Abdel-Wahed RT, El-Shahat MF (2015) Treatment of industrial wastewater using advanced oxidation processes. International J Sci Agric Sci 2(Proceedings):68–78

Andrzejewski P, Nawrocki J (2007) N-nitrosodimethylamine formation during treatment with strong oxidants of dimethylamine containing water. Water Sci Tech 56:125–131. https://doi.org/10.2166/wst.2007.802

Andrzejewski P, Kasprzyk-Hordern B, Nawrocki J (2008) N-nitrosodimethylamine (NDMA) formation during ozonation of dimethylamine-containing waters. Water Res 42:863–870. https://doi.org/10.1016/j.watres.2007.08.032

Andrzejewski P, Dabrowska A, Fijolek L, Szweda F (2011) Dimethylamine as a precursor to N-nitrosodimethylamineand formaldehyde in water. Ochrona Srodowiska 33(3):25–28

Andrzejewski P, Fijołek L, Nawrocki J (2012) An influence of hypothetical products of dimethylamine ozonation on N-nitrosodimethylamine formation. J Haz Mat 229–230:340–345. https://doi.org/10.1016/j.jhazmat.2012.06.009

Anipsitakis GP, Dionysiou DD (2003) Degradation of organic contaminants in water with sulfate radicals generated by the conjunction of peroxymonosulfate with Cobalt. Environ Sci Technol 37:4790–4797. https://doi.org/10.1021/es0263792

Anipsitakis GP, Dionysiou DD (2004) Radical generation by the interaction of transition metals with common oxidants. Environ Sci Technol 38:3705–3712. https://doi.org/10.1021/es035121o

Babuponnusami A, Muthukumar K (2014) A review on Fenton and improvements to the Fenton process for wastewater treatment. J Environ Chem Eng 2:557–572

Bavasso I, Di Palma L, Petrucci E (2016) Treatment of wastewater in H-Type MFC with protonic exchange membrane: experimental study of organic carbon and ammonium reduction with electrochemical characterization. Chem Eng Trans 47:223–228

Berlin AA (1986) Kinetics of radical-chain decomposition of persulfate in aqueous solutions of organic compounds. Kinetic Katal 27:34–39

Chandra R, Bharagava RN, Kapley A, Purohit HJ (2011) Bacterial diversity, organic pollutants and their metabolites in two aeration lagoons of common effluent treatment plant (CETP) during the degradation and detoxification of tannery wastewater. Bioresour Technol 102:2333–2341

Choi J, Valentine RL (2002) Formation of N-nitrosodimethylamine (NDMA) from reaction of monochloramine: a new disinfection by-product. Water Res 36:817–824. https://doi.org/10.1016/S0043-1354(01)00303-7

Chowdhury M, Mostafa MG, Biswas TK, Saha AK (2013) Treatment of leather industrial effluents by filtration and coagulation processes. Water Resour Ind 3:11–22

Chuang YH, Mitch WA (2017) Effect of ozonation and biological activated carbon treatment of wastewater effluents on formation of N-nitrosamines and halogenated disinfection byproducts. Environ Sci and Techn 51:2329–2338. https://doi.org/10.1021/acs.est.6b04693

De Filippis P, Liuzzo G, Scarsella M, Verdone N (2011) Oxidative desulfurization II: temperature dependence of organosulfur compounds oxidation. Ind Eng Chem Res 50:10452–10457

De Filippis P, Di Palma L, Scarsella M, Verdone N (2013) Biological denitrification of high nitrate wastewaters: a comparison between three electron donors. Chem Eng Trans 32:319–324

Deghles A, Kurt U (2016) Treatment of raw tannery wastewater by electrocoagulation technique: optimization of effective parameters using Taguchi method. Desalin Water Treat 57:14798–14809

Di Palma L, Bavasso I, Sarasini F, Tirillò J, Puglia D, Dominici F, Torre L (2018) Synthesis, characterization and performance evaluation of Fe3O4/PES nano composite membranes for microbial fuel cell. Eur Polym J 99:222–229

Du X, Zhang Y, Hussain I, Huang S, Huang W (2017) Insight into reactive oxygen species in persulfate activation with copper oxide: Activated persulfate and trace radicals. Chem Eng J 313:1023–1032. https://doi.org/10.1016/j.cej.2016.10.138

Durai G, Rajasimman M (2011) Biological treatment of tannery wastewater—a Revie. J Environ Sci Technol 4:1–17

Fu F, Dionysiou DD, Liu H (2014) The use of zero-valent iron for groundwater remediation and wastewater treatment: a review. J Hazard Mater 267:194–205

Gosu V, Gurjar BR, Surampalli RY, Zhang TC (2016) Treatment of pyridine-bearing wastewater by Nano Zero-valent iron supported on activated carbon-derived from agricultural waste. Desalin Water Treat 57:6250–6260

Hodaifa G, Ochando-Pulido JM, Rodriguez-Vives S, Martinez-Ferez A (2013) Optimization of continuous reactor at pilot scale for olive-oil mill wastewater treatment by Fenton-like process. Chem Eng J 220:117–124

Hu J, Dong H, Qu J, Qiang Z (2017) Enhanced degradation of iopamidol by peroxymonosulfate catalyzed by two pipe corrosion products (CuO and σ-MnO2). Water Res 112:1–8. https://doi.org/10.1021/acssuschemeng.8b01634

Kang YW, Hwang KY (2000) Effects of reaction conditions on the oxidation efficiency in the Fenton process. Water Res 34:2786–2790

Kuang Y, Wang Q, Chen Z, Megharaj M, Naidu R (2013) Heterogeneous Fenton-like oxidation of monochlorobenzene using green synthesis of iron nanoparticles. J Colloid Interface Sci 410:67–73

Lee C, Schmidt C, Yoon J, von Gunten U (2007) Oxidation of N-Nitrosodimethylamine (NDMA) precursors with ozone and chlorine dioxide: kinetics and effect on NDMA formation potential. Environ Sci Tech 41:2056–2063. https://doi.org/10.1021/es062484q

Liu WH, Zhang CG, Gao PF, Liu H, Song YQ, Yang JF (2017) Advanced treatment of tannery wastewater using the combination of UASB, SBR, electrochemical oxidation and BAF. J Chem Technol Biotechnol 92:588–597

Mandal T, Dasgupta D, Mandal S, Datta S (2010) Treatment of leather industry wastewater by aerobic biological and Fenton oxidation process. J Hazard Mater 180:204–211

Mitch WA, Sedlak DL (2002) Formation of N-nitrosodimethylamine (NDMA) from dimethylamine during chlorination. Environ Sci Tech 36:588–595. https://doi.org/10.1021/es010684q

Naumczyk J, Rusiniak M (2005) Physicochemical and chemical purification of tannery wastewaters. Polish J Environ Stud 14(6):789–797

Nawrocki J, Andrzejewski P (2011) Review, nitrosamines and water. J Hazard Mat 189:1–18. https://doi.org/10.1016/j.jhazmat.2011.02.005

Ochando-Pulido JM, Stoller M (2015) Kinetics and boundary flux optimization of integrated photocatalysis and ultrafiltration process for two-phase vegetation and olive washing wastewaters treatment. Chem Eng J 279:387–395

Ochando-Pulido JM, Stoller M, Di Palma L, Martinez-Ferez A (2014) Threshold performance of a spiralwound reverse osmosis membrane in the treatment of olive mill effluents from two-phase and three-phase extraction processes. Chem Eng Process 83:64–70

Oya M, Kosaka K, Asami M, Kunikane S (2008) Formation of N-nitrosodimethylamine (NDMA) by ozonation of dyes and related compounds. Chemosphere 73:1724–1730. https://doi.org/10.1016/j.chemosphere.2008.09.026

Park K, Choi S, Lee S, Kweon J, Song J (2016) Comparison of formation of disinfection by-products by chlorination and ozonation of wastewater effluents and their toxicity to Daphnia magna. Environ Pollut 215:314–321. https://doi.org/10.1016/j.envpol.2016.04.001

Przywara L (2017) Application of Fenton’s process for treatment of tannery wastewater. Ecol Eng 18(2):117–122

Rameshraja D, Suresh S (2011) Treatment of tannery wastewater by various oxidation and combined processes review. J Environ Res 5(2):349–360

Reemtsma T, Putschew A, Jekel M (1999) Industrial wastewater analysis: a toxicity-directed approach. Waste Manage 19:181–188

Schrank SG, José HJ, Moreira RFPM, Schröder HF (2005) Applicability of Fenton and H2O2/UV reactions in the treatment of tannery wastewaters. Chemosphere 60:644–655

Song Z, William CJ, Edyvean RG (2004) Treatment of tannery wastewater by chemical coagulation. Desalination 164:249–259

Stoller M, Ochando-Pulido JM, Di Palma L, Martinez-Ferez A (2015) Membrane process enhancement of 2-phase and 3-phase olive mill wastewater treatment plants by photocatalysis with magnetic-core titanium dioxide nanoparticles. J Ind Eng Chem 30:147–152

Tambosi JL, Di Domenico M, Schirmer WN, José HJ, de Moreira RF (2006) Treatment of paper and pulp wastewater and removal of odorous compounds by a Fenton-like process at the pilot scale. J Chem Technol Biotechnol 81:1426–1432

Vilardi G (2018) Bimetallic nZVI-induced chemical denitrification modelling using the shrinking core model. Chem Eng Trans 70:235–240

Vilardi G, Ochando-Pulido JM, Stoller M, Verdone N, Di Palma L (2018a) Fenton oxidation and chromium recovery from tannery wastewater by means of iron-based coated biomass as heterogeneous catalyst in fixed-bed columns. Chem Eng J 351:1–11

Vilardi G, Rodríguez-Rodríguez J, Ochando-Pulido JM, Verdone N, Martinez-Ferez A, Di Palmaa L (2018b) Process safety and large laboratory-plant application for the treatment of a tannery wastewater by fenton oxidation: Fe(II) and nZVI catalysts comparison and kinetic modeling. Environ Protect 117:629–638

Vilardi G, Rodriguez-Rodriguezb J, Ochando-Pulidob JM, Di Palmaa L, Verdonea N (2019) Fixed-bed reactor scale-up and modelling for Cr(VI) removal using nano iron-based coated biomass as packing material. Chem Eng J 361:990–998

Vuppala S, Di Palma L, Cianfrini C, Stoller M (2017) Flocculation and nanofiltration processes with insight of fouling phenomena for the treatment of olive mill wastewater. Chem Eng Trans 60:265–270

Wang K, Li W, Gong X, Li X, Liu W, He C, Wang Z, Minh QN, Chen CL, Wang JY (2014) Biological pretreatment of tannery wastewater using a full-scale hydrolysis acidification system. Int Biodeterior Biodegrad 95:41–45

Xing MY, Can D, Godefraid B, Yang J (2006) Treatment of pharmaceutical wastewater containing recalcitrant compounds in a Fenton-coagulation process. J Environ Sin 18(3):459–463

Yang L, Chen Z, Shen J, Xu Z, Liang H, Tian J, Ben Y, Zhai X, Shi W, Li G (2009) Reinvestigation of the nitrosamine-formation mechanism during ozonation. Environ Sci Tech 43:5481–5487. https://doi.org/10.1021/es900319f

Yang B, Tian Z, Zhang L, Guo Y, Yan S (2015) Enhanced heterogeneous Fenton degradation of methylene blue by nanoscale zero valent iron (nZVI) assembled on magnetic Fe3O4/reduced graphene oxide. J Water Process Eng 5:101–111

Zhang H, Andrews SA (2013) Factors affecting catalysis of copper corrosion products in NDMA formation from DMA in simulated premise plumbing. Chemosphere 93:2683–2689. https://doi.org/10.1016/j.chemosphere.2013.08.067

Zhang T, Chen Y, Wang J, Le Roux Y, Yang Y, Croué JP (2014) Efficient peroxydisulfate activation process not relying on sulfate radical generation for water pollutant degradation. Environ Sci Technol 48:5868–5875. https://doi.org/10.1021/es501218f

Acknowledgements

This research was supported within the framework of the Polish National Center for Research and Development, project no. UDA-POIG.01.04.00-30-012/10-0

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rykowska, I., Andrzejewski, P., Wolski, R. et al. Dimethylamine oxidation by homogenic (Fe+2 and UV) and heterogenic (CuO) activated peroxydisulfate. Chem. Pap. 75, 993–1003 (2021). https://doi.org/10.1007/s11696-020-01354-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-020-01354-4