Abstract

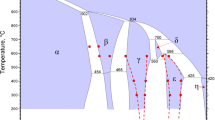

The solid-solid interfacial reaction in the Mg-Cu binary diffusion couples was studied at temperatures of 673, 703 and 733 K, with reaction time ranging from 24 to 72 h. MgCu2 and Mg2Cu were formed between Mg and Cu matrixes at the studied temperatures. The growths of MgCu2 and Mg2Cu followed the parabolic kinetics, which suggests that the growth of the two phases is controlled by bulk diffusion mechanisms. The activation energies for growths of MgCu2 and Mg2Cu were determined to be 147.57 ± 1.49 and 139.12 ± 1.30 kJ/mol, respectively. The interdiffusion coefficients were evaluated as functions of compositions in MgCu2 and Mg2Cu intermetallic phases at the studied temperatures, which were further utilized for evaluating the activation energies and frequency factors for interdiffusion in each phase. The Mg impurity diffusion coefficient in Cu was higher than the Cu impurity diffusion coefficient in Mg. The activation energy and pre-exponential factor for diffusion of Mg impurity in Cu were determined to be 139.38 ± 0.65 kJ/mol and 1.02(±0.26) × 10−4 m2/s, respectively, while those for diffusion of Cu impurity in Mg were determined to be 164.04 ± 7.18 kJ/mol and 3.10(±0.31) × 10−3 m2/s, respectively.

Similar content being viewed by others

References

M. Kiani, I. Gandikota, M. Rais-Rohani, and K. Motoyama, Design of Lightweight Magnesium Car Body Structure Under Crash and Vibration Constraints, J. Magnes. Alloys, 2014, 2(2), p 99-108

A.A. Luo, Magnesium Casting Technology for Structural Applications, J. Magnes. Alloys, 2013, 1(1), p 2-22

B.L. Mordike and T. Ebert, Magnesium: Properties-Applications-Potential, Mater. Sci. Eng., A, 2001, 302(1), p 37-45

M. Mezbahul-Islam, A.O. Mostafa, and M. Medraj, Essential Magnesium Alloys Binary Phase Diagrams and Their Thermochemical Data, J. Mater., 2014, doi:10.1155/2014/704283

J. Lei, H. Huang, X. Dong, J. Sun, B. Lu, M. Lei, Q. Wang, C. Dong, and G. Cao, Formation and Hydrogen Storage Properties of In Situ Prepared Mg-Cu Alloy Nanoparticles by Arc Discharge, Int. J. Hydrogen Energy, 2009, 34(19), p 8127-8134

K. Tanaka, H.T. Takeshita, K. Kurumatani, H. Miyamura, and S. Kikuchi, The Effect of Initial Structures of Mg/Cu Super-Laminates on Hydrogen Absorption/Desorption Properties, J. Alloys Compd., 2013, 580, p S222-S225

S.K. Das and I.-H. Jung, Effect of the Basal Plane Orientation on Al and Zn Diffusion in hcp Mg, Mater. Charact., 2014, 94, p 86-92

S. Brennan, K. Bermudez, N.S. Kulkarni, and Y. Sohn, Interdiffusion in the Mg-Al System and Intrinsic Diffusion in β-Mg2Al3, Metall. Mater. Trans. A, 2012, 43(11), p 4043-4052

A. Mostafa and M. Medraj, On the Atomic Interdiffusion in Mg-{Ce, Nd, Zn} and Zn-{Ce, Nd} Binary Systems, J. Mater. Res., 2014, 29(13), p 1463-1479

J. Dai, B. Jiang, X. Li, Q. Yang, H. Dong, X. Xia, and F. Pan, The Formation of Intermetallic Compounds During Interdiffusion of Mg-Al/Mg-Ce Diffusion Couples, J. Alloys Compd., 2015, 619, p 411-416

K. Nonaka, T. Sakazawa, and H. Nakajima, Reaction diffusion in Mg-Cu system, Mater. Trans., JIM, 1995, 36, p 1463-1466

Q.Z. Hong and F.M. d’Heurle, The Dominant Diffusing Species and Initial Phase Formation in Al-Cu, Mg-Cu, and Mg-Ni Systems, J. Appl. Phys., 1992, 72(9), p 4036

C. Coughanowr, I. Ansara, R. Luoma, M. Hamalainen, and H. Lukas, Assessment of the Cu-Mg System, Z. Metallkd., 1991, 82(7), p 574-581

P.D. Lee and J.D. Hunt, Hydrogen Porosity in Directional Solidified Aluminium-Copper Alloys: In Situ Observation, Acta Mater., 1997, 45(10), p 4155-4169

M.S.A. Karunaratne, P. Carter, and R.C. Reed, On the Diffusion of Aluminium and Titanium in the Ni-Rich Ni-Al-Ti System Between 900 and 1200 Degrees C, Acta Mater., 2001, 49(5), p 861-875

H. Strandlund and H. Larsson, Prediction of Kirkendall Shift and Porosity in Binary and Ternary Diffusion Couples, Acta Mater., 2004, 52(15), p 4695-4703

C. Matano, Phys (Trans), 8, 109 (1933), in Proc. Phys. Math. Soc. Japan, 1933, p 405

T. Heumann, ‘Zur Berechnung von Diffusions Koeffizienten bei Einund Mehrphasiger Diffusion in Festen Legierungen, Z. Physik. Chem., 1952, 201(1), p 168-187, in German

L.D. Hall, An Analytical Method of Calculating Variable Diffusion Coefficients, J. Chem. Phys., 1953, 21(1), p 87-89

K. Lal. Diffusion of Some Elements in Magnesium, CEA Report, 1967, p 54

K. Lal, V. Levy. Study of the Diffusion of Cerium and Lanthanum in Magnesium, Compt. Rend., Ser. C, 1966, 262, p 107

L. Jin, D. Kevorkov, M. Medraj, and P. Chartrand, Al-Mg-RE (RE = La, Ce, Pr, Nd, Sm) Systems: Thermodynamic Evaluations and Optimizations Coupled with Key Experiments and Miedema’s Model Estimations, J. Chem. Thermodyn., 2013, 58, p 166-195

V.F. Yerko, V.F. Zeleniskiy, and V.S. Krasnorutskiy, Difuzija Berillija v Magnii, Fiz. Met. Metalloved., 1966, 22(1), p 112-114, in Slovenian

L.V. Pavlinov, A.M. Gladyshev, and V.N. Bykov, Self-Diffusion in Calcium and Diffusion of Barely Soluble Impurities in Magnesium and Calcium, Phys. Met. Metall., 1968, 26(5), p 53-59

S. Brennan, A.P. Warren, K.R. Coffey, N. Kulkarni, P. Todd, M. Kilmov, and Y. Sohn, Aluminum Impurity Diffusion in Magnesium, J. Phase Equilib. Diffus., 2012, 33(2), p 121-125

K. Maier, Self-Diffusion in Copper at “Low” Temperatures, Phys. Status Solidi A, 1977, 44(2), p 567-576

Acknowledgments

The authors are grateful for the financial supports from Chongqing Science and Technology Commission (CSTC2013jcyjC60001, cstc2012ggB50003, cstc2013jcyjA50020), National Natural Science Foundation of China (51171212, 51474043, 51531002), and The National Science and Technology Program of China (2013DFA71070, 2013CB632200), and the Fundamental Research Funds for the Central Universities (CDJZR13138801, CDJXS12131106), Postdoctoral Science Foundation of China (2015M572452).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dai, J., Jiang, B., Zhang, J. et al. Diffusion Kinetics in Mg-Cu Binary System. J. Phase Equilib. Diffus. 36, 613–619 (2015). https://doi.org/10.1007/s11669-015-0417-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-015-0417-z