Abstract

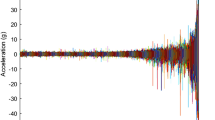

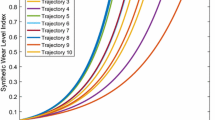

In the context of rotating machinery maintenance, this study examines diagnostic, prognostic and health management (PHM) techniques, where a set of signal processing and supervised machine learning processes are used in a precise strategy that allows us to diagnose the condition of a gas turbine and also to predict its remaining useful life (RUL), to make appropriate maintenance decisions. Using a database of historical vibration signals, partial failure due to misalignment is diagnosed by Fast Fourier Transform (FFT) analysis. This partial failure can evolve into a total failure, leading to the cessation of production and higher maintenance costs. Predictive maintenance can improve its ability to predict failure phenomena using data-driven degradation modeling. On this basis, a total failure of a gas turbine can be avoided. A set of temporal and frequency health indicators are extracted at each operating cycle to be analyzed, filtered, and improved using statistical techniques such as normalization methods and correlation analysis. Additionally, the rolling average is used based on window functions and monotonicity to choose the best and most reliable indicators. Before fitting the decay curves of the selected health indicators using an exponential regression model, they were combined into a single indicator by applying the principal component analysis (PCA) technique to facilitate the adjustment process. The results showed good performance after testing the exponential model to predict the RUL on the test data.

Similar content being viewed by others

References

Y.G. Li, P. Nilkitsaranont, Gas turbine performance prognostic for condition-based maintenance. Appl. Energy. 86(10), 2152–2161 (2009). https://doi.org/10.1016/j.apenergy.2009.02.011

A. Mehalaine, O. Berkani, Experimental study on vibration analysis of rotor-stator rub defect in a gas turbine generator set. J. Fail. Anal. Prev. (2023). https://doi.org/10.1007/s11668-023-01739-z

H. Xiong, Y. Peng, Y. Hu, L. Zhang, Y. Li, Vibration fault signal analysis and diagnosis of flue gas turbine. Eng. Fail. Anal. 134, 105981 (2022). https://doi.org/10.1016/j.engfailanal.2021.105981

R. Ahmad, S. Kamaruddin, An overview of time-based and condition-based maintenance in industrial application. Comput. Ind. Eng. 63(1), 135–149 (2012). https://doi.org/10.1016/j.cie.2012.02.002

R.M. Ayo-Imoru, A.C. Cilliers, A survey of the state of condition-based maintenance (CBM) in the nuclear power industry. Ann. Nucl. Energy. 112, 177–188 (2018). https://doi.org/10.1016/j.anucene.2017.10.010

Q. Wang, Y. Xiao, S. Wang, W. Liu, X. Liu, A method for constructing automatic rolling bearing fault identification model based on refined composite multi-scale dispersion entropy. IEEE Access. 9, 86412–86428 (2021). https://doi.org/10.1109/ACCESS.2021.3089251

M. Achouch, M. Dimitrova, K. Ziane, S. Sattarpanah Karganroudi, R. Dhouib, H. Ibrahim et al., On predictive maintenance in industry 4.0: overview, models, and challenges. Appl. Sci. 12(16), 8081 (2022)

K.T.P. Nguyen, K. Medjaher, A new dynamic predictive maintenance framework using deep learning for failure prognostics. Reliab. Eng. Syst. Saf. 188, 251–262 (2019). https://doi.org/10.1016/j.ress.2019.03.018

J.J. Montero Jimenez, S. Schwartz, R. Vingerhoeds, B. Grabot, M. Salaün, toward multi-model approaches to predictive maintenance: a systematic literature survey on diagnostics and prognostics. J. Manuf. Syst. 56, 539–557 (2020). https://doi.org/10.1016/j.jmsy.2020.07.008

M. Kordestani, M. Saif, M.E. Orchard, R. Razavi-Far, K. Khorasani, Failure prognosis and applications—a survey of recent literature. IEEE Trans. Reliab. 70(2), 728–748 (2021). https://doi.org/10.1109/TR.2019.2930195

M. Pech, J. Vrchota, J. Bednář, Predictive maintenance and intelligent sensors in smart factory: review. Sensors. 21(4), 1470 (2021)

M. Jasiulewicz Kaczmarek, A. Gola, Maintenance 4.0 technologies for sustainable manufacturing-an overview. IFAC-PapersOnLine. 52(10), 91–96 (2019). https://doi.org/10.1016/j.ifacol.2019.10.005

W. Mao, J. He, J. Tang, Y. Li, Predicting remaining useful life of rolling bearings based on deep feature representation and long short-term memory neural network. Adv. Mech. Eng. 10(12), 1687814018817184 (2018). https://doi.org/10.1177/1687814018817184

Poor P, Ženíšek D, Basl J. Historical overview of maintenance management strategies: development from breakdown maintenance to predictive maintenance in accordance with four industrial revolutions. (2019)

N. Omri, Z. Al Masry, N. Mairot, S. Giampiccolo, N. Zerhouni, Industrial data management strategy toward an SME-oriented PHM. J. Manuf. Syst. 56, 23–36 (2020). https://doi.org/10.1016/j.jmsy.2020.04.002

S. Adams, M. Malinowski, G. Heddy, B. Choo, P.A. Beling, The WEAR methodology for prognostics and health management implementation in manufacturing. J. Manuf. Syst. 45, 82–96 (2017). https://doi.org/10.1016/j.jmsy.2017.07.002

C. Byington, M. Watson, M.J. Roemer, T.R. Galic, J.J. McGroarty, Prognostic enhancements to gas turbine diagnostic systems. IEEE Aerospace Conf. 103, 3247–55 (2003). https://doi.org/10.1109/AERO.2003.1234168

T. Brotherton, G. Jahns, J. Jacobs, D. Wroblewski, Prognosis of faults in gas turbine engines. Proceedings. 6, 163–71 (2000). https://doi.org/10.1109/AERO.2000.877892

S. Wang, Q. Wang, Y. Xiao, W. Liu, M. Shang, Research on rotor system fault diagnosis method based on vibration signal feature vector transfer learning. Eng. Fail. Anal. 139, 106424 (2022). https://doi.org/10.1016/j.engfailanal.2022.106424

M. de Castro-Cros, M. Velasco, C. Angulo, Machine-learning-based condition assessment of gas turbines & mdash: a review. Energies. 14(24), 8468 (2021)

M. Yadegari, Real time prognostic strategies: application to gas turbines. Defect. Diffus. Forum. 312–315, 601–606 (2011). https://doi.org/10.4028/www.scientific.net/DDF.312-315.601

13381-1:2015 I. Condition monitoring and diagnostics of machines—Prognostics—part 1: general guidelines.

M. Wang, H. Wang, L. Cui, G. Xiang, X. Han, Q. Zhang et al., Remaining useful life prediction for aero-engines based on time-series decomposition modeling and similarity comparisons. Aerospace. 9(10), 609 (2022)

T. Berghout, M. Benbouzid, A systematic guide for predicting remaining useful life with machine learning. Electronics. 11(7), 1125 (2022)

Anis MD, Editor toward remaining useful life prediction in rotating machine fault prognosis: an exponential degradation model. 2018 condition monitoring and diagnosis (CMD); 2018 23-26 Sept. 2018.

A. Heng, S. Zhang, A.C.C. Tan, J. Mathew, Rotating machinery prognostics: state of the art, challenges and opportunities. Mech. Syst. Signal Process. 23(3), 724–739 (2009). https://doi.org/10.1016/j.ymssp.2008.06.009

X. Kong, J. Yang, Remaining useful life prediction of rolling bearings based on RMS-MAVE and dynamic exponential regression model. IEEE Access. 7, 169705 (2019). https://doi.org/10.1109/ACCESS.2019.2954915

S. Sajid, A. Haleem, S. Bahl, M. Javaid, T. Goyal, M. Mittal, Data science applications for predictive maintenance and materials science in context to Industry 4.0. Mater. Today Proc. 45, 4898–905 (2021). https://doi.org/10.1016/j.matpr.2021.01.357

C. Hu, B.D. Youn, P. Wang, Y.J. Taek, Ensemble of data-driven prognostic algorithms for robust prediction of remaining useful life. Reliab. Eng. Syst. Saf. 103, 120–135 (2012). https://doi.org/10.1016/j.ress.2012.03.008

K. Javed, R. Gouriveau, N. Zerhouni, State of the art and taxonomy of prognostics approaches, trends of prognostics applications and open issues toward maturity at different technology readiness levels. Mech. Syst. Signal Process. 94, 214–236 (2017). https://doi.org/10.1016/j.ymssp.2017.01.050

B. Wang, Y. Lei, N. Li, N. Li, A hybrid prognostics approach for estimating remaining useful life of rolling element bearings. IEEE Trans. Reliab. 69(1), 401–412 (2020). https://doi.org/10.1109/TR.2018.2882682

Bejaoui I, Bruneo D, Xibilia MG, editors. A data-driven prognostics technique and RUL prediction of rotating machines using an exponential degradation model. 2020 7th international conference on control, decision and information technologies (CoDIT); 2020 29 June-2 July 2020.

N.M. Thoppil, V. Vasu, C.S.P. Rao, Health indicator construction and remaining useful life estimation for mechanical systems using vibration signal prognostics. Int. J. Syst. Assur. Eng. Manag. 12(5), 1001–1010 (2021). https://doi.org/10.1007/s13198-021-01190-z

W. Caesarendra, T. Tjahjowidodo, A review of feature extraction methods in vibration-based condition monitoring and its application for degradation trend estimation of low-speed slew bearing. Machines. 5(4), 21 (2017)

M. Tahan, E. Tsoutsanis, M. Muhammad, Z.A. Abdul Karim, Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: a review. Appl. Energy. 198, 122–44 (2017). https://doi.org/10.1016/j.apenergy.2017.04.048

K.M. Al-Hussain, I. Redmond, Dynamic response of two rotors connected by rigid mechanical coupling with parallel misalignment. J. Sound Vib. 249(3), 48398 (2002). https://doi.org/10.1006/jsvi.2001.3866

M. Akhtar, M.S. Kamran, N. Hayat, A.U. Rehman, A.A. Khan, High-vibration diagnosis of gas turbines: an experimental investigation. J. Vib. Control. 27(1–2), 3–17 (2020). https://doi.org/10.1177/1077546320923917

S. Cofre-Martel, E.L. Droguett, M. Modarres, Big machinery data preprocessing methodology for data-driven models in prognostics and health management. Sensors. 21(20), 6841 (2021). https://doi.org/10.3390/s21206841

Y. Lei, Signal processing and feature extraction, in Intelligent Fault diagnosis and remaining useful life prediction of rotating machinery. (Elsevier, New York, 2017), p.17–66. https://doi.org/10.1016/B978-0-12-811534-3.00002-0

P. Jain, S. Bhosle, Analysis of vibration signals caused by ball bearing defects using time-domain statistical indicators. Int. J. Adv. Technol. Eng. Exp. 9, 700–715 (2022). https://doi.org/10.19101/IJATEE.2021.875416

Brownlee J. Data preparation for machine learning: data cleaning, feature selection, and data transforms in python: machine learning mastery; 2020. https://books.google.dz/books?id=uAPuDwAAQBAJ

B. Ratner, The correlation coefficient: Its values range between +1/−1, or do they? J. Target. Meas. Anal. Mark. 17(2), 139–142 (2009). https://doi.org/10.1057/jt.2009.5

F. Elasha, S. Shanbr, X. Li, D. Mba, Prognosis of a wind turbine gearbox bearing using supervised machine learning. Sensors. 19(14), 3092 (2019)

E. Zivot, J. Wang, Time series regression modeling, in Modeling financial time series with S-Plus®. ed. by E. Zivot, J. Wang (Springer, New York, 2003), p.167–207

S. Karamizadeh, S. Abdullah, A. Manaf, M. Zamani, A. Hooman, An overview of principal component analysis. J Signal Inform Process. (2013). https://doi.org/10.4236/jsip.2013.43B031

M. Ringnér, What is principal component analysis? Nat. Biotechnol. 26(3), 303–304 (2008). https://doi.org/10.1038/nbt0308-303

G. Liu, W. Fan, F. Li, G. Wang, D. You, Remaining useful life prediction of nuclear power machinery based on an exponential degradation model. Sci. Technol. Nuclear Inst. 2022, 9895907 (2022). https://doi.org/10.1155/2022/9895907

I. Bejaoui, D. Bruneo, M.G. Xibilia, Remaining useful life prediction of broken rotor bar based on data-driven and degradation model. Appl. Sci. 11(16), 7172 (2021)

Botchkarev A (2018) Performance metrics (error measures) in machine learning regression, forecasting and prognostics: Properties and typology. arXiv preprint arXiv:180903006

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdelfettah, M., Oualid, B. Predicting the Remaining Useful Life of a Gas Turbine Based on an Exponential Degradation Model. J Fail. Anal. and Preven. (2024). https://doi.org/10.1007/s11668-024-01921-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11668-024-01921-x