Abstract

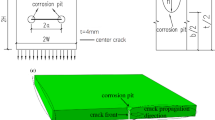

Local discontinuities and stress concentrations caused by pitting corrosion on a component can significantly affect the mechanical performance of a structure. To deeply understand the problems, specimens are created from high-strength steel DH 36 and tests are performed to analyze the flexural behavior of plate specimens with different pitting crater parameters, pitting distribution and pitting interaction. The results show that both the pitting diameter and pitting depth have negative effects on mechanical performance of specimen and the volume loss rate is more suitable to be used as damage indicator to describe the degradation in mechanical properties of specimens with pitting. Moreover, when the corrosion region suffers from compressive loads the specimen can carry more loads than tensile case. In addition, it was found that cracks firstly appear at the edge of pit due to stress concentration and evolve toward the width and thickness directions of specimen. After cracks reach the bottom of pit they stop evolving, which indicates that stresses are not the reason causing the specimen failure for undamaged one.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study were supplied by Xueshu Liu under license and so cannot be made freely available. Requests for access to these data should be made to Xueshu Liu through liuxs@dlut.edu.cn.

References

G. Timco, Isolated ice floe impacts. Cold Reg. Sci. Technol. 68, 35–48 (2011)

M. Storheim, J. Amdahl, Design of offshore structures against accidental ship collisions. Mar. Struct. 37, 135–172 (2014)

N. Abdussamie, Y. Drobyshevski, R. Ojeda, G. Thomas, W. Amin, Experimental investigation of wave-in-deck impact events on a TLP model. Ocean Eng. 142, 541–562 (2017)

D. Truong, H. Jung, H. Shin, S. Cho, Response of low-temperature steel beams subjected to single and repeated lateral impacts. Int. J. Nav. Archit. Ocean Eng. 10, 670–682 (2018)

D. Truong, H. Shin, S. Cho, Repeated lateral impacts on steel grillage structures at room and sub-zero temperatures. Int. J. Impact Eng. 113, 40–53 (2018)

X. He, Y. Garbatov, C.G. Soares, Analysis of pseudo-shakedown of rectangular plates under repeated impacts. Ocean Eng. 265, 112609 (2022)

W. Cai, L. Zhu, X. Qian, Dynamic response of steel plates under repeated ice impacts. Int. J. Impact Eng. 162, 104129 (2022)

S. Sultana, Y. Wang, A. Sobey, J. Wharton, R. Shenoi, Influence of corrosion on the ultimate compressive strength of steel plates and stiffened panels. Thin Walled Struct. 96, 95–104 (2015)

J. Bhandari, F. Khan, R. Abbassi, V. Garaniya, R. Ojeda, Modelling of pitting corrosion in marine and offshore steel structures—a technical review. J. Loss Prev. Process Ind. 37, 39–69 (2015)

H. Wang, Y. Yu, J. Yu, C. Jin, Y. Zhao, Z. Fan, Y. Zhang, Effect of 3d random pitting defects on the collapse pressure of pipe—Part II: numerical analysis. Thin Walled Struct. 129, 527–541 (2018)

Y. Yao, Y. Yang, Z. He, Y. Wang, Experimental study on generalized constitutive model of hull structural plate with multi-parameter pitting corrosion. Ocean Eng. 170, 407–415 (2018)

Z. Hu, L. Hua, J. Liu, S. Min, C. Li, F. Wu, Numerical simulation and experimental verification of random pitting corrosion characteristics. Ocean Eng. 240, 110000 (2021)

L. Feng, D. Huang, X. Chen, H. Shi, S. Wang, Residual ultimate strength investigation of offshore pipeline with pitting corrosion. Appl. Ocean Res. 117, 102869 (2021)

R. Wang, R. Shenoi, A. Sobey, Ultimate strength assessment of plated steel structures with random pitting corrosion damage. J. Constr. Steel Res. 143, 331–342 (2018)

G. Li, C. Hou, L. Shen, G. Yao, Performance and strength calculation of CFST columns with localized pitting corrosion damage. J. Constr. Steel Res. 188, 107011 (2022)

J. Silva, Y. Garbatov, C. Soares, Ultimate strength assessment of rectangular steel plates subjected to a random localised corrosion degradation. Eng. Struct. 52, 295–305 (2013)

L. Feng, K. Hong, D. Li, H. Shi, Ultimate torsional strength assessment of large deck opening stiffened box girder subjected to pitting corrosion. Ocean Eng. 251, 111059 (2022)

S. Shojai, P. Schaumann, M. Braun, S. Ehlers, Influence of pitting corrosion on the fatigue strength of offshore steel structures based on 3D surface scans. Int. J. Fatigue. 164, 107128 (2022)

O. Fatoba, R. Akid, On the behaviour of small fatigue cracks emanating from corrosion pits: part I–the influence of mechanical factors. Theor. Appl. Fract. Mech. 117, 103154 (2022)

C. Chen, Z. Jie, K. Wang, Fatigue life evaluation of high-strength steel wires with multiple corrosion pits based on the TCD. J. Constr. Steel Res. 186, 106913 (2021)

J. Balbin, V. Chaves, N. Larrosa, Pit to crack transition and corrosion fatigue lifetime reduction estimations by means of a short crack microstructural model. Corros. Sci. 180, 109171 (2021)

S. Xu, Y. Wang, Estimating the effects of corrosion pits on the fatigue life of steel plate based on the 3d profile. Int. J. Fatigue. 72, 27–41 (2015)

P. Hu, Q. Meng, W. Hu, F. Shen, Z. Zhan, L. Sun, A continuum damage mechanics approach coupled with an improved pit evolution model for the corrosion fatigue of aluminum alloy. Corros. Sci. 113, 78–90 (2016)

O. Fatoba, R. Akid, Uniaxial cyclic elasto-plastic deformation and fatigue failure of API-5L X65 steel under various loading conditions. Theor. Appl. Fract. Mech. 94, 147–159 (2018)

Y. Yang, R. Huang, Z. He, Experimental study of the uniaxial compressive behavior of DH36 steel plates with mechanically induced pits. Ocean Eng. 200, 107058 (2020)

J. Mendoza, P. Haagensen, J. Kohler, Analysis of fatigue test data of retrieved mooring chain links subject to pitting corrosion. Mar. Struct. 81, 103119 (2022)

Z. Guo, Y. Ma, L. Wang, J. Zhang, Modelling guidelines for corrosion-fatigue life prediction of concrete bridges: considering corrosion pit as a notch or crack. Eng. Fail. Anal. 105, 883–895 (2019)

C. Miao, R. Li, J. Yu, Effects of characteristic parameters of corrosion pits on the fatigue life of the steel wires. J. Constr. Steel Res. 168, 105879 (2020)

M. Moreira, M. Borges, Assessment of electrochemical machining-induced pitting geometry on fatigue performance of flexible pipes’ tensile armor wires. Res. Eng. 15, 100485 (2022)

Acknowledgments

This work was supported by the Open Project Program of Shandong Marine Aerospace Equipment Technological Innovation Center, Ludong University (Grant No. MAETIC2021-04). The authors would like to acknowledge the above financial supports.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

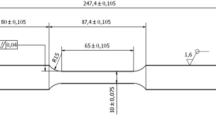

Liu, X., Yan, B. & Sun, H. Experimental Study of Flexural Behavior of DH36 Steel Plates with Mechanically Induced Pits Under Cyclic Loading. J Fail. Anal. and Preven. 23, 2378–2385 (2023). https://doi.org/10.1007/s11668-023-01773-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01773-x