Abstract

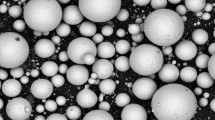

Titanium alloy (Ti6Al4V) is extensively used in the fabrication of upper stage propellant tanks for satellite launch vehicles. These tanks are of welded construction and are made from three types of domes and 5 types of rings. This paper investigates the occurrence of X-ray radiography and fluorescent penetrant indications in a specific ring component of the tank assembly after machining to thickness of 1.7 mm. The affected ring, with dimensions OD-φ1400 mm, ID-φ1300 mm, and height 410 mm, exhibited a multitude of surface and embedded indications across eight sectors, spanning approximately 140 mm in height at the mid-section of the ring. To ascertain the root cause of these indications, a comprehensive metallurgical analysis was conducted, involving X-ray radiography, optical/electron microscopy, and mechanical testing. By correlating non-destructive observations with microscopic findings, this study establishes that the occurrence of defects can be attributed to a combination of raw material and deformation processing issues. The results contribute to a better understanding of the factors influencing the quality of Ti6Al4V propellant tank rings and aid in the development of improved manufacturing processes.

Similar content being viewed by others

References

G. Henson, C.S. Jone III, Materials for Launch Vehicle Structures. Aerospace Materials and Application, 2018.

A. Norman, et al., Advanced Manufacturing of Titanium Propellant Tanks for Space Applications Part 1: Tank Design and Demonstrator Manufacturing. CEAS Space J., pp. 1–11 (2021).

W. Tam, M. Hersh, I. Ballinger, Hybrid propellant tanks for spacecraft and launch vehicles. in 39th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit (2003)

R. Williamson et al., A demonstration of melt rate control during VAR of “Cracked” electrodes. J. Mater. Sci. 39(24), 7161–7168 (2004)

K. Chan, G. Leverant, L. Perocchi, Constitutive properties of hard-alpha titanium. Metall. Mater. Trans. A. 31(12), 3029–3040 (2000)

J. Bellot et al., Dissolution of hard-alpha inclusions in liquid titanium alloys. Metall. Mater. Trans. B. 28(6), 1001–1010 (1997)

R. Gupta et al., Solution treatment and aging of thick rings from titanium alloy Ti6Al4V. Met. Sci. Heat Treat. 57(3), 169–174 (2015)

S. Tamirisakandala, R. Bhat, B. Vedam, Recent advances in the deformation processing of titanium alloys. J. Mater. Eng. Perform. 12(6), 661–673 (2003)

A. Mitchell, Melting, casting and forging problems in titanium alloys. Mater. Sci. Eng. A. 243(1–2), 257–262 (1998)

S. Semiatin, V. Seetharaman, I. Weiss, Hot workability of titanium and titanium aluminide alloys: an overview. Mater. Sci. Eng. A. 243(1–2), 1–24 (1998)

S. Seagle, K. Yu, S. Giangiordano, Considerations in processing titanium. Mater. Sci. Eng. A. 263(2), 237–242 (1999)

T. Seshacharyulu et al., Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti–6Al–4V. Mater. Sci. Eng. A. 279(1–2), 289–299 (2000)

Y. Prasad, et al. Hot deformation mechanisms in Ti–6Al–4V with transformed β starting microstructure: commercial v. extra low interstitial grade. Mater. Sci. Technol. 16(9), 1029–1036 (2000)

Acknowledgments

Authors wish to thank the internal expert committee on titanium alloy ring defect analysis and NDT team for their guidance and support. Authors wish to express their deep sense of gratitude to Group Director, Materials and Metallurgy Group and Deputy Director, Materials and Mechanical Entity for their encouragement and support during this work. Authors are thankful to Director, VSSC for his permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nayan, N., Gupta, R.K., Anil Kumar, V. et al. Metallurgical Investigation and Root Cause Analysis of Defects in a Titanium Alloy (Ti6Al4V) Propellant Tank Ring. J Fail. Anal. and Preven. 23, 1484–1490 (2023). https://doi.org/10.1007/s11668-023-01712-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01712-w