Abstract

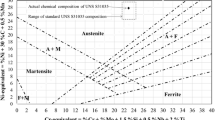

The paper investigates the reason for the cracking and leaking of stainless-steel (SS) tanks used to store processed hot water in rice boiling and husking plants. A detailed analysis of tank specimen samples using radiography, optical metallography, scanning electron microscopy, EDAX reveals that stress corrosion cracking (SCC) is the prime reason for the failure. The presence of favorable microstructure, environment and stress promoted the nucleation and propagation of SCC in the tank weldment. The evolution of the microstructure in the selected stainless grade was studied and discussed using Scheffler–Delong diagram. The formation of martensite in low nickel, high nitrogen austenitic stainless steel was observed to significantly influence the mechanical properties and promote SCC. The decreased pitting corrosion resistance of the material compared to SS 316 alloy was an important factor in the initiation of pits which acted as nucleation sites for SCC.

Similar content being viewed by others

References

R.L. Plaut, C. Herrera, D.M. Escriba, P.R. Rios, A.F. Padilha, A short review on wrought austenitic stainless steels at high temperatures: processing, microstructure, properties and performance. Mater. Res. 10(4), 453–460 (2007). https://doi.org/10.1590/S1516-14392007000400021

M. Talha, C.K. Behera, O.P. Sinha, A review on nickel-free nitrogen containing austenitic stainless steels for biomedical applications. Mater. Sci. Eng. C. 33(7), 3563–3575 (2013). https://doi.org/10.1016/j.msec.2013.06.002

H. Baba, T. Kodama, Y. Katada, Role of nitrogen on the corrosion behavior of austenitic stainless steels. Corros. Sci. 44(10), 2393–2407 (2002). https://doi.org/10.1016/S0010-938X(02)00040-9

D. Eliezer, D.G. Chakrapani, C.J. Altstetter, E.N. Pugh, The influence of austenite stability on the hydrogen embrittlement and stress-corrosion cracking of stainless steel. Metall. Trans. A. 10(7), 935–941 (1979). https://doi.org/10.1007/BF02658313

P.C. Pistorius. Low-nickel austenitic stainless steels: metallurgical constraints, pp. 911–917 (2010).

E. Kalácska, B. Varbai, J. Ginsztler, K. Májlinger, TIG and MIG welding of high strength Cr-Mn and Cr-Ni alloyed austenitic stainless steel combinations. IOP Conf. Ser. Mater. Sci. Eng. 426, 012021 (2018). https://doi.org/10.1088/1757-899X/426/1/012021

Z. Liu et al., Gas metal arc welding of high nitrogen stainless steel with Ar–N2–O2 ternary shielding gas. Def. Technol. (2020). https://doi.org/10.1016/j.dt.2020.05.021

P.A.A. Khan, T. Debroy, Alloying element vaporization and weld pool temperature during laser welding of AlSl 202 stainless steel. Metall. Trans. B. 15(4), 641–644 (1984). https://doi.org/10.1007/BF02657284

W. Chuaiphan, L. Srijaroenpramong, Effect of welding speed on microstructures, mechanical properties and corrosion behavior of GTA-welded AISI 201 stainless steel sheets. J. Mater. Process. Technol. 214(2), 402–408 (2014). https://doi.org/10.1016/j.jmatprotec.2013.09.025

E.A. Krivonosova, A review of stress corrosion cracking of welded stainless steels. OALib. 05(05), 1–41 (2018). https://doi.org/10.4236/oalib.1104568

S.M. Elsariti, Behaviour of stress corrosion cracking of austenitic stainless steels in sodium chloride solutions. Procedia Eng. 53, 650–654 (2013). https://doi.org/10.1016/j.proeng.2013.02.084

A.I. Karayan, H. Castaneda, Weld decay failure of a UNS S31603 stainless steel storage tank. Eng. Fail. Anal. 44, 351–362 (2014). https://doi.org/10.1016/j.engfailanal.2014.05.008

A.D. Schino, J.M. Kenny, Effect of grain size on the corrosion resistance of a high nitrogen-low nickel austenitic stainless steel, p. 3

C. Garcia, F. Martin, P. de Tiedra, Y. Blanco, M. Lopez, Pitting corrosion of welded joints of austenitic stainless steels studied by using an electrochemical minicell. Corros. Sci. 50(4), 1184–1194 (2008). https://doi.org/10.1016/j.corsci.2007.11.028

B.T. Lu, Z.K. Chen, J.L. Luo, B.M. Patchett, Z.H. Xu, Pitting and stress corrosion cracking behavior in welded austenitic stainless steel. Electrochim. Acta. 50(6), 1391–1403 (2005). https://doi.org/10.1016/j.electacta.2004.08.036

F. Bottoli, M.S. Jellesen, T.L. Christiansen, G. Winther, M.A.J. Somers, High temperature solution-nitriding and low-temperature nitriding of AISI 316: effect on pitting potential and crevice corrosion performance. Appl. Surf. Sci. 431, 24–31 (2018). https://doi.org/10.1016/j.apsusc.2017.06.094

P. Guiraldenq, O. Hardouin Duparc, The genesis of the Schaeffler diagram in the history of stainless steel. Metall. Res. Technol. 114(6), 613 (2017). https://doi.org/10.1051/metal/2017059

R. Saluja, K.M. Moeed, The emphasis of phase transformations and alloying constituents on hot cracking susceptibility of type 304l and 316l stainless steel welds. Int. J. Eng. Sci. Technol. 4(5), 2206–2212 (2012)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vijayan, V., Ravichandran, G., Rao, M. et al. Failure Analysis of the High Nitrogen Austenitic Stainless-Steel Boiler Tank Weldments. J Fail. Anal. and Preven. 21, 976–982 (2021). https://doi.org/10.1007/s11668-021-01142-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-021-01142-6