Abstract

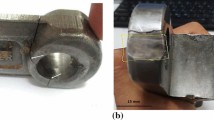

A detailed failure analysis was carried out on a broken chain link made from high-strength manganese steel which failed while in service at a cement factory. Metallographic and microhardness testing revealed the presence of a dual structure within the failed link: a softer low-precipitate chill zone at the outer periphery and a hard and brittle inner structure typified by columnar grain structure and high volume of both inter- and intragranular carbide precipitation. The present failure is believed to have initiated at the outer surface by a contact rolling fatigue action within the softer structure and further augmented by the presence of shrinkage porosity and the inner brittle structure. The development of the observed failure is discussed in terms of microstructure and mechanical properties of the material of manufacture, and practical recommendations are presented at the end of the paper.

Similar content being viewed by others

References

M. Oezel, T. Janitzky, P. Beiss, C. Broeckmann, Influence of steel cleanliness and heat treatment conditions on rolling contact fatigue of 100Cr6. Wear 430–431, 272–279 (2019)

S. Dhar, H.K. Danielsen, S. Fæster, C.J. Rasmussen, D. Juul Jensen, 2D and 3D characterization of rolling contact fatigue cracks in manganese steel wing rails from a crossing. Wear 436–437, 202959 (2019)

V.L. Volodin, L.B. Zuev, T.V. Volodin, V.E. Gromov, Structure, strength, and wear resistance of hadfield steel subjected to surface magnetic-pulse treatment. Steel Transl. 39(8), 629–632 (2009)

A.A. Gulyaev, Y. Tyapkin, V.A. Golikov, V.S. Sharinova, The fine structure of hadfield steel. Met. Sci. Heat Treat. 27(6), 411–415 (1985)

L. Niu, Y. Xu, H. Wu, Microstructure and mechanical properties of high-Cr cast iron bars reinforced Hadfield steel matrix composites. J. Wuhan Univ. Technol. Mater. Sci. Ed. 25(3), 464–468 (2010). https://doi.org/10.1007/s11595-010-0024-0

M. Sabzi, S.M. Far, S.M. Dezfuli, Effect of melting temperature on microstructural evolutions, behavior and corrosion morphology of Hadfield austenitic manganese steel in the casting process. Int. J. Miner. Metall. Mater. 25(12), 1431 (2018). https://doi.org/10.1007/s12613-018-1697-1

S. Dhara, H.K. Danielsen, S. Fæster, C. Rasmussen, Y. Zhang, D.J. Jensen, Crack formation within a Hadfield manganese steel crossing nose. Wear 438–439, 1–9 (2019). https://doi.org/10.1016/j.wear.2019.203049

D.K. Subramanyam, Austenitic Manganese Steels, in ASM Handbook Volume 1; Properties and Selection: Irons; Steels and High-Performance Alloys, 10th Ed., eds. by S.R. Lampman, T.B. Zorc (1993), pp. 1951–2003

C.-p. Liu, P.-t. Liu, J.-z. Pan, C.-h. Chen, R.-m. Ren, Effect of pre-wear on the rolling contact fatigue property of D2 wheel steel. Wear 442–443, 203154 (2020)

B. Allison, A. Pandkar, Critical factors for determining a first estimate of fatigue limit of bearing steels under rolling contact fatigue. Int. J. Fatigue 117, 396–406 (2018)

A. Holmberg, M. Andersson, Å.K. Rudolphi, Rolling fatigue life of PM steel with different porosity and surface finish. Wear 426–427, 454–461 (2019)

M. Ueda, K. Matsuda, Effects of carbon content and hardness on rolling contact fatigue resistance in heavily loaded pearlitic rail steels. Wear 444–445, 203120 (2020)

D. Zeng, X. Tian, W. Liu, L. Liantao, J. Zhang, Y. Gong, Investigation on rolling contact fatigue of railway wheel steel with surface defect. Wear 446–447, 203207 (2020)

V.K. Sharma, Roller contact fatigue study of austempered ductile iron. J. Heat. Treat. 3(4), 326–334 (1984)

D. Scott, Rolling contact fatigue, in Treatise on Materials Science and Technology: Wear, ed. by D. Scott (Elsevier, Amsterdam, 1979), pp. 321–361

M. Taraf, E.H. Zahaf, O. Oussouaddi, A. Zeghloul, Numerical analysis for predicting the rolling contact fatigue crack initiation in a railway wheel steel. Tribol. Int. 43, 585–593 (2010)

K. Tanaka, T. Mura, A dislocation model for fatigue crack initiation. J. Appl. Mech. 48, 97–103 (1981)

H.J. Böhmer, Wälzverschleiß und -ermüdung von Bauteilen und Maßnahmen zu ihrer Einschränkung. Mat.-wiss. u. Werkstofftech. 29, 697–713 (1998). https://doi.org/10.1002/mawe.19980291203

H. Winter, H.R. Rösch, Einfluss des Schlupfes auf die Wälzfestigkeit von Rollen. Antriebstechnik 14(9), 505–513 (1975)

M. Sabzia, S.M. Dezfuli, Post weld heat treatment of hypereutectoid hadfield steel: characterization and control of microstructure, phase equilibrium, mechanical properties and fracture mode of welding joint. J. Manuf. Process. 34, 313–328 (2018). https://doi.org/10.1016/j.jmapro.2018.06.009

J.W. Ringsberg, M. Loo-Morrey, B.L. Josefson, Prediction of fatigue crack initiation for rolling contact fatigue. Int. J. Fatigue 22, 205–215 (2000)

H.D. Grohmann, K. Hempelmann, A. Grob-Thebing, A new type of RCF, experimental investigations and theoretical modeling. Wear 253, 67–74 (2002)

B. Lv, M. Zhang, F.C. Zhang, C.L. Zheng, X.Y. Feng, L.H. Qian, X.B. Qin, Micro-mechanism of rolling contact fatigue in Hadfield steel crossing. Int. J. Fatigue 44, 273–278 (2012). https://doi.org/10.1016/j.ijfatigue.2012.04.010

J. Liu, A dynamic modelling method of a rotor-roller bearing housing system with a localized fault including the additional excitation zone. J. Sound Vib. 469, 115144 (2020)

R. Harzallah, A. Mouftiez, E. Felder, S. Hariri, J.P. Maujean, Rolling contact fatigue of Hadfield steel X120Mn12. Wear 269, 647–654 (2010). https://doi.org/10.1016/j.wear.2010.07.001

J. Kang, F.C. Zhang, X.Y. Long, B. Lv, Cyclic deformation and fatigue behaviors of Hadfield manganese steel. Mater. Sci. Eng. A591, 59–68 (2014). https://doi.org/10.1016/j.msea.2013.10.072

B. Garmeh, M. Kasiri-Asgarani, K. Amini, H. Ghayour, Analysis of Hadfield Scrap Shredder Hammer Fracture and replacing it with Carbide-free Nano-Bainitic Steel. Eng. Fail. Anal. (2019). https://doi.org/10.1016/j.engfailanal.2019.104230

W.D. Pilkey, D.F. Pilkey, Peterson’s Stress Concentration Factors, 3rd edn. (Wiley, New York, 2008)

M. Ciavarella, P. Decuzzi, The state of stress induced by the plane frictionless cylindrical contact. I. The case of elastic similarity. Int. J. Solids Struct. 38, 4507–4523 (2001)

M. Ciavarella, P. Decuzzi, The state of stress induced by the plane frictionless cylindrical contact. II. The case of elastic similarity. Int. J. Solids Struct. 38, 4525–4533 (2001)

Acknowledgments

The experimental part of this study was carried out at the laboratories of ACUREN Group INC., Mississauga, Ontario, Canada, where the first author held the position of a senior metallurgical failure analyst. The help and support of ACUREN technical and managerial staff is highly appreciated. This work was originally conducted for Holcim-Canada, Mississauga, L5J 1K1, ON, Canada. The permission granted by Holcim-Canada to publish this work is highly appreciated. Provision of bucket elevator images by Infinity for Cement Equipment and The Arab Cement Co. is mostly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdul Jawwad, A.K. Metallurgical Failure Analysis of a High-Strength-Steel Drag Chain Conveyor Link. J Fail. Anal. and Preven. 20, 647–656 (2020). https://doi.org/10.1007/s11668-020-00879-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00879-w