Abstract

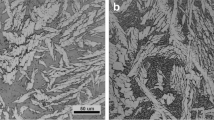

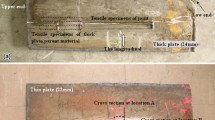

Linz–Donawitz (LD) vessel is an integral part of the blast furnace–basic oxygen furnace route of steelmaking. Failures of the LD vessel can result in safety issues as well as production loss. In the event of any such failure, the thrust should be to carry out the investigation at the minimum lead time and suggest for corrective actions to prevent any recurrence in the future. For this purpose, an on-site or in situ nondestructive method of investigation can be extremely useful. Present work is a case study of analysis of cracking of the shell of a vessel. Visual observation revealed that a large crack of around 6.5 m length developed at the bottom of the top cone connected to the vertical portion of the vessel shell by means of welding. Crack had propagated along the weld. The investigation consisted of chemical analysis using portable x-ray florescence spectroscopy, hardness testing across the weld and replica technique for microstructural analysis. These were aided by detailed analysis of refractory wall thickness measurements and thermography data for over a year. The study revealed that the failure occurred in thermo-mechanical fatigue mode from the weld joint due to use of inferior welding electrode. In contrast to the micro-alloyed base metal, no precipitation strengthening was present at the weld zone that resulted in the onset of softening mechanism therein. Recommendations are provided to prevent similar failures in the future.

Similar content being viewed by others

References

L. Sun, H. Jin, Y. Li, J. Xi, Research on steelmaking-continuous casting production scheduling problem based on augmented lagrangian relaxation algorithm under multi-coupling constraints. IFAC Pap OnLine 52, 820–825 (2019)

A. Saha, Boiler tube failures: some case studies, in Handbook of Materials Failure Analysis with Case Studies from the Chemicals, Concrete and Power Industries, 2016, pp. 49–68

F. Dehnavi, A. Eslami, F. Ashrafizadeh, A case study on failure of superheater tubes in an industrial power plant. Eng. Fail. Anal. 80, 368–377 (2017)

K. Kishore, S. Mukhopadhyay, G. Mukhopadhyay, M. Adhikary, S. Bhattacharyya, Movable hood tube in LD convertor: failure analysis and coating solution. Eng. Fail. Anal. 105, 25–39 (2019)

U. Pal, G. Mukhopadhyay, Creep failure analysis of tie rod used in lifting steel vessels. Eng. Fail. Anal. 104, 300–307 (2019)

N. Tanaka, H. Kikuchi, K. Iwata, Creep-fatigue failure test and analysis of a vessel-type structure subjected to cyclic thermal transients. Nucl. Eng. Des. 140, 349–372 (1993)

L.H. Toft, R.A. Marsden, The structure and properties of 1%Cr–0.5%Mo steel after service in CEGB power stations, Structural Processes in Creep, ISI Special Report 70, Iron and Steel Institute, London (1961) pp. 276–294

D. Jiao, Q. Cai, H. Wu, Y. Ren, Effect of Nb on austenite recrystallization in high temperature deformation process. J. Iron. Steel Res. Int. 17, 39–44 (2010)

H. Bhadeshia, R. Honeycombe, Steels: Microstructures and Properties, 4th edn. (Butterworth-Heinemann, Oxford, 2017)

D.A. Spera, What Is Thermal Fatigue? Thermal Fatigue of Materials and Components (American Society for Testing and Materials, West Conshohocken, 1976), pp. 3–9

Acknowledgments

Authors are thankful to Ashish Kumar, Ishwar Lal and Moti Lal for support provided in situ metallography inside the vessel. Authors express sincere gratitude to the management of Tata Steel for providing adequate support in the analysis and permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kishore, K., Singh, R., Nirmal, B. et al. In Situ Failure Investigation of Weld Cracking in a Linz–Donawitz Vessel. J Fail. Anal. and Preven. 20, 555–562 (2020). https://doi.org/10.1007/s11668-020-00864-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00864-3