Abstract

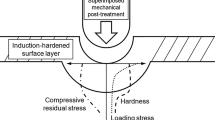

Bow shackle failures, over the years, raised the question whether these failures are attributed to microstructural changes along the profile of the shackle or due to the geometry of the shackle. Bow shackles forged from 080M40 (EN8) material were subjected to different heat treatments in order to alter the microstructure thereof. The shackles were 3D-scanned prior to fatigue testing, and the data points were imported into engineering simulation software (ANSYS), to build a finite element model of each shackle tested. The shackles were subjected to five different fatigue load cases, which represented typical loads experienced at termination points for an overhead line with a span length of 400 m, with changes in conductor type, configuration, wind and ice loading. The fatigue tests revealed that the improvement in fatigue performance with an increase in hardness was limited to the lower load levels. In addition, the finite element model indicated that the misalignment of the bolt holes results in unequal load distribution between the two legs, with a considerable increase in the bending stress experienced by the leg carrying the higher loading. The influence of the bow shape of the shackle was confirmed by testing straight-leg shackles also manufactured from 080M40 material, which outperformed the fatigue performance of the bow shackles. Furthermore, misalignment of the bolt holes for the straight shackles did not have the same detrimental effect compared to the bow shackle. Although the change in microstructure does influence the fatigue performance, this investigation concludes that the combined influences of the curved leg and misalignment of the bolt holes pose a greater impact on the fatigue performance of bow shackles than microstructure. Furthermore, the fatigue performance of line hardware shackles is significantly improved by changing the geometry of the shackle from a curved leg to a straight leg.

Similar content being viewed by others

References

ESKOM, Specification for Suspension and Strain Assemblies and for Hardware for Transmission Lines (Eskom, Sandton, 2014)

P.F. Wieser, Supplement 11: Hardenability and Heat Treatment, in Steel Castings Handbook (Crystal Lake: Steel Founders’ Society of America, 1980), 5 edn

J. Calitz, Investigation into the Shackle Failure Incidents (Eskom Research, Testing and Development, Investigation, Sandton, 2012)

C.V. Cronje, Straight Shackle Body—210 kN 27 mm Opening (Babcock Ntuthuko Powerlines, Nigel, 2015)

ASTM, E 466-96. Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials (West Conshohocken: ASTM International, 2002)

SANS, 10280-1. Overhead Power Lines for Conditions Prevailing in South Africa. Part 1: Safety (Pretoria: SABS Standards Division, 2013), pp. 30, 33

C.V. Cronje, Shackle Straight (Bow)—210 kN 27 mm Opening (Babcock Ntuthuko Powerlines, Nigel, 2011)

Acknowledgments

The lead author would like to acknowledge Eskom Holdings SOC Limited for their commitment to providing him with the opportunity to further his engineering skills and knowledge. Through Eskom’s vision in the Eskom Power Plant Engineering Institute (EPPEI) programme, he is able to pursue his doctoral degree in engineering.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Calitz, J., Kok, S. & Delport, D. The Effect of Geometry on the Fatigue Life of Overhead Line Hardware. J Fail. Anal. and Preven. 19, 1401–1406 (2019). https://doi.org/10.1007/s11668-019-00736-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00736-5