Abstract

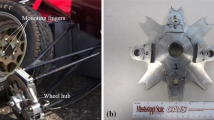

A number of wheel axles of MF-240 Tractors, which had broken after unusually short times in the field (~ 2–4 months), were examined to determine the cause of their failure. The fracture surface showed typical fatigue fracture that had initiated from a circular crack (about 2–3 mm deep) in the induction-hardened layer at the ‘neck’ region of the axle. A scrutiny of the production data showed that the failed axles were all from those which were induction-hardened during the winter months. A further probe revealed that sometimes the induction-hardened axles were left overnight without tempering. It appeared highly likely that quenching stresses in the induction-hardened layer of those components which were left un-tempered during cold winter nights were responsible for the ‘delayed cracking.’ In an attempt to verify this hypothesis, a simulated test was conducted which confirmed that delayed cracking could occur if induction-hardened axles were kept un-tempered overnight at low ambient temperatures. Another interesting and rare feature of the present fracture was that the fatigued area was ‘curved,’ i.e., the fatigue crack, as it progressed, had gradually acquired an orientation that was normal to the maximum operative tensile stress.

Similar content being viewed by others

References

Metals Handbook, Vol 10: Failure Analysis and Prevention, 8th edn. (American Society for Metals, 1975, pp. 74, 113)

V.I. Sarrak, G.A. Filippov, Delayed fracture of quenched steel, in Problems of Metal Science and Physics of Metals, Metallurgiya, (Moscow, 1973), p. 134 (in Russian)

Metals Handbook, Vol 11: Failure Analysis and Prevention, 9th edn. (American Society of Metals, 1989), p. 2307

R. Kern, Distortion and cracking, III: How to control cracking. Heat Treat. (in English) 27(4), 38–42 (1985)

Quench Cracks- 3 Ways to Recognize. https://pmpaspeakingofprecision.com/tag/quench-crack,2013. Accessed 15 Mar 2018

Metals Handbook, Vol 17: Non Destructive Evaluation and Quality Control, 9th edn. (American Society of Metals, 1989), pp. 137–145

Dye Penetrant Inspection. https://en.wikipedia.org/wiki/Dye_penetrant_inspection,2017. Accessed 15 Mar 2018

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shad, M.R., ul Hasan, F. Failure Analysis of Tractor Wheel Axle. J Fail. Anal. and Preven. 18, 1631–1634 (2018). https://doi.org/10.1007/s11668-018-0561-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0561-y