Abstract

This study establishes a machine learning (ML) model utilizing the expectation-maximization approach to predict maximum residual stresses, encompassing both tensile and compressive states, in the cold spraying process across various substrates. The main feature of the ML algorithm lies in its two-step iterative process, where the Expectation (E step) refines latent variable estimates, and the Maximization (M step) optimizes the model’s parameters, aligning them with the data. Based on the results, regression analysis highlighted the predictive capabilities of the proposed model for tensile and compressive residual stresses, exhibiting root mean square error values of 8.8 and 3.5%, along with determination coefficient values of 0.915 and 0.968, respectively, indicating higher prediction performance in the compression mode. This suggests higher predictability for residual stress within the depth of material’s body. Moreover, analyzing low residual stress levels underscored the significant impact of substrate and particle mechanical strength on prediction performance, whereas higher residual stress levels highlighted the strong influence of thermal conductivity. This correlation suggests that high stresses during the cold spray process generate more heat, thereby emphasizing the crucial role of thermal conductivity in predicting resultant residual stresses. Furthermore, a notable trend emerges as tensile stress increases, spotlighting the augmented influence of processing parameters in the prediction process. Conversely, at elevated compressive stresses, material properties’ weight factors assume a vital role in predictions. These findings offer insights into the intricate interplay between processing parameters and materials properties in determining resultant residual stresses during cold spraying.

Similar content being viewed by others

Abbreviations

- \(\bar{\sigma }\) :

-

Flow stress

- A, B, C, m, and n :

-

Material constants

- \({\overline{\varepsilon }}^{pl}\) :

-

Equivalent plastic strain

- \({\dot{\varepsilon }}^{pl}\) :

-

Equivalent plastic strain rate

- \({\dot{\varepsilon }}_{0}^{pl}\) :

-

Reference strain rate

- T ref :

-

Reference temperature

- T m :

-

Melting temperature of the material

- \({\overline{\varepsilon }}_{{\text{pf}}}\) :

-

Equivalent plastic strain at material failure

- p :

-

Contact pressure

- q :

-

Von Mises stress

- d1-d5:

-

Failure parameters

- L new :

-

The normalized value of specified parameter

References

H. Wang, P. Li, W. Guo, G. Ma, and H. Wang, Copper-Based Composite Coatings by Solid-State Cold Spray Deposition: A Review, Coatings, 2023, 13, p 479.

W. Sun, X. Chu, H. Lan, R. Huang, J. Huang, Y. Xie, J. Huang, and G. Huang, Current Implementation Status of Cold Spray Technology: A Short Review, J. Therm. Spray Technol., 2022, 31, p 848-865.

M.A. Adaan-Nyiak and A.A. Tiamiyu, Recent Advances on Bonding Mechanism in Cold Spray Process: A Review of Single-Particle Impact Methods, J. Mater. Res., 2023, 38, p 69-95.

D.C. Saha, J.V.S.N. Sripada, G.C. Saha, and H. Jahed, Microstructure and Interfacial Bonding Evolution of Cold Spray Deposited Graphene-Reinforced Composite Feedstock on AZ80 Magnesium Substrate, J. Therm. Spray Technol., 2023, 32, p 984-1001.

S. Kumar, Influence of Processing Conditions on the Mechanical, Tribological and Fatigue Performance of Cold Spray Coating: A Review, Surf. Eng., 2022, 38, p 324-365.

S. Yin, N. Fan, C. Huang, Y. Xie, C. Zhang, R. Lupoi, and W. Li, Towards High-Strength Cold Spray Additive Manufactured Metals: Methods, Mechanisms, and Properties, J. Mater. Sci. Technol., 2023, 170, p 47.

A. Fardan, C.C. Berndt, and R. Ahmed, Numerical Modelling of Particle Impact and Residual Stresses in Cold Sprayed Coatings: A Review, Surf. Coatings Technol., 2021, 409, 126835. https://doi.org/10.1016/j.surfcoat.2021.126835

X. Pan, W. He, L. Zhou, S. Shu, X. Ding, Q. Wang, S. Wen, N. Li, M. Yi, Y. Zhu, and J. Nan, Two Laser Beam Modulation of Microstructure and Residual Stress Field in Cold Sprayed Al Alloy for Recovering Fatigue Performance, Int. J. Plast., 2023, 164, 103598. https://doi.org/10.1016/j.ijplas.2023.103598

A. Faheem, A. Tyagi, F. Hasan, A.A. Khan, Q. Murtaza, and K.K. Saxena, Residual Stress Investigation in the Metallic Coating Approach of Micro-sized Particles on the Substrate: Cold Spray Additive Manufacturing, Adv. Mater. Process. Technol., 2022, 8, p 4642-4658. https://doi.org/10.1080/2374068X.2022.2079250

Z. Zhang, Z. Liu, J. Zhao, B. Wang, and Y. Cai, Numerical Analysis of Residual Stresses Induced by Cold Spray Fabricating cBN-reinforced Ni Matrix Composites, Surf. Coat. Technol., 2023, 467, 129672. https://doi.org/10.1016/j.surfcoat.2023.129672

A. Vargas-Uscategui, P.C. King, M.J. Styles, M. Saleh, V. Luzin, and K. Thorogood, Residual Stresses in Cold Spray Additively Manufactured Hollow Titanium Cylinders, J. Therm. Spray Technol., 2020, 29, p 1508-1524. https://doi.org/10.1007/s11666-020-01028-3

M. Daroonparvar, H.R. Bakhsheshi-Rad, A. Saberi, M. Razzaghi, A.K. Kasar, S. Ramakrishna, P.L. Menezes, M. Misra, A.F. Ismail, and S. Sharif, Surface Modification of Magnesium Alloys Using Thermal and Solid-State Cold Spray Processes: Challenges and Latest Progresses, J. Magn. Alloy., 2022, 10(8), p 2025-2061.

K. Loke, Z.Q. Zhang, S. Narayanaswamy, P.K. Koh, V. Luzin, T. Gnaupel-Herold, and A.S.M. Ang, Residual Stress Analysis of Cold Spray Coatings Sprayed at Angles Using Through-Thickness Neutron Diffraction Measurement, J. Therm. Spray Technol., 2021, 30, p 1810-1826. https://doi.org/10.1007/s11666-021-01252-5

B. Marzbanrad, E. Toyserkani, and H. Jahed, Customization of Residual Stress Induced in Cold Spray Printing, J. Mater. Process. Technol., 2021, 289, 116928. https://doi.org/10.1016/j.jmatprotec.2020.116928

S. Lett, A. Quet, S. Hémery, J. Cormier, E. Meillot, and P. Villechaise, Residual Stresses Development During Cold Spraying of Ti-6Al-4V Combined with In Situ Shot Peening, J. Therm. Spray Technol., 2023, 32, p 1018-1032. https://doi.org/10.1007/s11666-022-01514-w

D. Boruah, B. Ahmad, T.L. Lee, S. Kabra, A.K. Syed, P. McNutt, M. Doré, and X. Zhang, Evaluation of Residual Stresses Induced by Cold Spraying of Ti-6Al-4V on Ti-6Al-4V Substrates, Surf. Coat. Technol., 2019, 374, p 591-602. https://doi.org/10.1016/j.surfcoat.2019.06.028

N.M. Dang, W.Y. Lin, Z.Y. Wang, S.A. Alidokht, R.R. Chromik, T.Y. Chen, and M.T. Lin, Mechanical Properties and Residual Stress Measurement of TiN/Ti Duplex Coating Using HiPIMS TiN on Cold Spray Ti, Coatings, 2022, 12, p 759. https://doi.org/10.3390/coatings12060759

D. Shrestha, F. Azarmi, and X.W. Tangpong, Effect of Heat Treatment on Residual Stress of Cold Sprayed Nickel-Based Superalloys, J. Therm. Spray Technol., 2022, 31, p 197-205. https://doi.org/10.1007/s11666-021-01284-x

V. Luzin, O. Kirstein, S.H. Zahiri, and D. Fraser, Residual Stress Buildup in Ti Components Produced by Cold Spray Additive Manufacturing (CSAM), J. Therm. Spray Technol., 2020, 29, p 1498-1507. https://doi.org/10.1007/s11666-020-01048-z

F. Meng, X. Fan, Z. Chi, S. Chen, and X. Chu, Modeling Parameters for Finite Element Simulation of Residual Stress in Cold Spray and the Stress Evolution and Distribution, J. Therm. Spray Technol., 2023 https://doi.org/10.1007/s11666-023-01640-z

E. Lin, Q. Chen, O.C. Ozdemir, V.K. Champagne, and S. Müftü, Effects of Interface Bonding on the Residual Stresses in Cold-Sprayed Al-6061: A Numerical Investigation, J. Therm. Spray Technol., 2019, 28, p 472-483. https://doi.org/10.1007/s11666-019-00827-7

K. Liu, M.F. Niri, G. Apachitei, M. Lain, D. Greenwood, and J. Marco, Interpretable Machine Learning for Battery Capacities Prediction and Coating Parameters Analysis, Control. Eng. Pract., 2022, 124, 105202.

X. Xu, X. Wang, S. Wu, L. Yan, T. Guo, K. Gao, X. Pang, and A.A. Volinsky, Design of Super-Hard High-Entropy Ceramics Coatings Via Machine Learning, Ceram. Int., 2022, 48, p 32064-32072.

Y. Gong, B. Cao, H. Zhang, F. Sun, and M. Fan, Terahertz Based Thickness Measurement of Thermal Barrier Coatings Using Hybrid Machine Learning. Nondestruct. Test. Eval., 2023, p 1-17.

A.S. Mohammed, S. Dodla, J.K. Katiyar, and M.A. Samad, Prediction of Friction Coefficient of su-8 and Its Composite Coatings Using Machine Learning Techniques, Proc. Inst. Mech. Eng. Part J. J. Eng. Tribol., 2023, 237, p 943-953.

Z. Wang, S. Cai, W. Chen, R.A. Ali, and K. Jin, Analysis of Critical Velocity of Cold Spray Based on Machine Learning Method with Feature Selection, J. Therm. Spray Technol., 2021, 30, p 1213-1225.

K. Malamousi, K. Delibasis, B. Allcock, and S. Kamnis, Digital Transformation of Thermal and Cold Spray Processes with Emphasis on Machine Learning, Surf. Coat. Technol., 2022, 433, 128138. https://doi.org/10.1016/j.surfcoat.2022.128138

H. Canales, I.G. Cano, and S. Dosta, Window of Deposition Description and Prediction of Deposition Efficiency Via Machine Learning Techniques in Cold Spraying, Surf. Coat. Technol., 2020, 401, 126143.

K. Bobzin, W. Wietheger, H. Heinemann, S.R. Dokhanchi, M. Rom, and G. Visconti, Prediction of Particle Properties in Plasma Spraying Based on Machine Learning, J. Therm. Spray Technol., 2021, 30, p 1751-1764.

G. Mauer and C. Moreau, Process Diagnostics and Control in Thermal Spray, J. Therm. Spray Technol., 2022, 31, p 818-828.

R. Valente, A. Ostapenko, B.C. Sousa, J. Grubbs, C.J. Massar, D.L. Cote, and R. Neamtu, Classifying Powder Flowability for Cold Spray Additive Manufacturing Using Machine Learning, in 2020 IEEE International Conference on Big Data (Big Data), (IEEE, 2020), pp 2919-2928

R. Ghelichi, S. Bagherifard, D. MacDonald, I. Fernandez-Pariente, B. Jodoin, and M. Guagliano, Experimental and Numerical Study of Residual Stress Evolution in Cold Spray Coating, Appl. Surf. Sci., 2014, 288, p 26-33.

W.K.W. Tai, R. Chakrabarty, S. Pinches, X. Huang, J. Lang, J. Song, and A.S.M. Ang, Comparing Relative Bond Characteristics Between Spherical and Elongated Morphologies for Cold Spray Process Using SPH Simulation, J. Therm. Spray Technol., 2022, 31, p 2489-2504.

R. Chakrabarty and J. Song, A Modified Johnson-Cook Material Model with Strain Gradient Plasticity Consideration for Numerical Simulation of Cold Spray Process, Surf. Coat. Technol., 2020, 397, 125981.

G.R. Johnson and W.H. Cook, Fracture Characteristics of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures, Eng. Fract. Mech., 1985, 21, p 31-48.

A.S.M. Ang and C.C. Berndt, A Review of Testing Methods for Thermal Spray Coatings, Int. Mater. Rev., 2014, 59, p 179-223.

A. Mehta, H. Vasudev, and L. Thakur, Applications of Numerical Modelling Techniques in Thermal Spray Coatings: A Comprehensive Review. Int. J. Interact. Des. Manuf., 2023, p 1-21.

N. Ferguen, W. Leclerc, and E.S. Lamini, Numerical Investigation of Thermal Stresses Induced Interface Delamination in Plasma-Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 2023, 461, 129449.

T.C. Chen, Expectation–Maximization Machine Learning Model for Micromechanical Evaluation of Thermally-Cycled Solder Joints in a Semiconductor, J. Phys. Condens. Matter, 2023, 35, 305901. https://doi.org/10.1088/1361-648X/accdab

M. Bocquet, J. Brajard, A. Carrassi, and L. Bertino, Bayesian Inference of Chaotic Dynamics by Merging Data Assimilation, Machine Learning and Expectation-Maximization. ArXiv Prepr. ArXiv2001.06270. (2020).

K. Greff, S. Van Steenkiste, and J. Schmidhuber, Neural Expectation Maximization. Adv. Neural Inf. Process. Syst., 2017, 30.

D. Singh and B. Singh, Investigating the Impact of Data Normalization on Classification Performance, Appl. Soft Comput., 2020, 97, 105524.

Y. Chauvin and D.E. Rumelhart, Backpropagation: Theory, Architectures, and Applications, Psychology Press, London, 2013.

L. Xu, M. Jordan, and G.E. Hinton, An Alternative Model for Mixtures of Experts. Adv. Neural Inf. Process. Syst., 1994, 7.

V. Samavatian, M. Fotuhi-Firuzabad, M. Samavatian, P. Dehghanian, and F. Blaabjerg, Correlation-Driven Machine Learning for Accelerated Reliability Assessment of Solder Joints in Electronics, Sci. Rep., 2020, 10, p 14821. https://doi.org/10.1038/s41598-020-71926-7

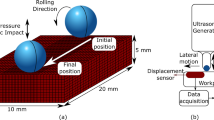

B. Marzbanrad, H. Jahed, and E. Toyserkani, On the Evolution of Substrate’s Residual Stress During Cold Spray Process: A Parametric Study, Mater. Des., 2018, 138, p 90-102.

O.C. Ozdemir, C.A. Widener, M.J. Carter, and K.W. Johnson, Predicting the Effects of Powder Feeding Rates on Particle Impact Conditions and Cold Spray Deposited Coatings, J. Therm. Spray Technol., 2017, 26, p 1598-1615.

Y. Zhang and C. Ling, A Strategy to Apply Machine Learning to Small Datasets in Materials Science, Npj Comput. Mater., 2018, 4, p 25.

B. Szabó and I. Babuška, Finite Element Analysis: Method Verification and Validation, Wiley, New Jersey, 2021.

H. Yeom, B. Maier, G. Johnson, T. Dabney, M. Lenling, and K. Sridharan, High Temperature Oxidation and Microstructural Evolution of Cold Spray Chromium Coatings on Zircaloy-4 in Steam Environments, J. Nucl. Mater., 2019, 526, 151737.

C. Singhal and Q. Murtaza, Simulation of Critical Velocity of Cold Spray Process with Different Turbulence Models, Mater. Today Proc., 2018, 5, p 17371-17379.

L. Palodhi and H. Singh, On the Dependence of Critical Velocity on the Material Properties During Cold Spray Process, J. Therm. Spray Technol., 2020, 29, p 1863-1875.

M.R. Rokni, S.R. Nutt, C.A. Widener, V.K. Champagne, and R.H. Hrabe, Review of Relationship Between Particle Deformation, Coating Microstructure, and Properties in High-Pressure Cold Spray, J. Therm. Spray Technol., 2017, 26, p 1308-1355.

Z. Arabgol, M.V. Vidaller, H. Assadi, F. Gärtner, and T. Klassen, Influence of Thermal Properties and Temperature of Substrate on the Quality of Cold-Sprayed Deposits, Acta Mater., 2017, 127, p 287-301.

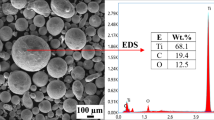

V.S. Bhattiprolu, K.W. Johnson, O.C. Ozdemir, and G.A. Crawford, Influence of Feedstock Powder and Cold Spray Processing Parameters on Microstructure and Mechanical Properties of Ti-6Al-4V Cold Spray Depositions, Surf. Coat. Technol., 2018, 335, p 1-12.

S. Singh, R.K.S. Raman, C.C. Berndt, and H. Singh, Influence of Cold Spray Parameters on Bonding Mechanisms: A Review, Metals (Basel), 2021, 11, p 2016.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aparco, R.H., Tapia-Tadeo, F., Ascarza, Y.B. et al. A Machine Learning Approach for Analyzing Residual Stress Distribution in Cold Spray Coatings. J Therm Spray Tech (2024). https://doi.org/10.1007/s11666-024-01776-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11666-024-01776-6