Abstract

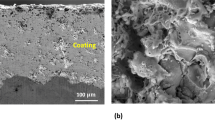

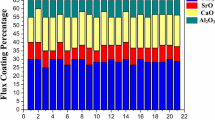

The use of advanced thermal spray technology for surface modification of aluminum alloy parts for automobiles can greatly improve the surface properties and service life of the parts while saving resources and reducing environmental pollution. In this paper, a Ni60A coating was prepared on the surface of aluminum alloy 109 (ZL109) by supersonic plasma spraying (HEPJet). The spraying process parameters were optimized based on the response surface methodology (RSM). The effects of the main factors such as spraying power, spraying distance, and Ar flow rate on the porosity and microhardness of the coating were analyzed by the Box–Behnken method (BBD). The response surface of the porosity and microhardness of the coating was constructed by establishing the appropriate mathematical model. The response surface of porosity and microhardness of the coating was constructed by establishing a relevant mathematical model. The results show that the established mathematical model is reliable, and the spray power has the greatest influence on the porosity and microhardness of the coating. The optimal porosity and microhardness of the coating predicted by the model are 0.85% and 971.1HV0.1, respectively, which is close to the experimental results. The porosity and microhardness of the coating measured by the experiment are 0.87% and 959.8HV0.1, respectively. The coatings prepared with optimal parameters have good compactness, small porosity, and high hardness.

Similar content being viewed by others

References

A. Poznak, D. Freiberg, and P. Sanders, Automotive Wrought Aluminium Alloys//Fundamentals of Aluminium Metallurgy, Woodhead Publishing, Cambridge, 2018, p 333–386

S. Divya, D. Elavarasan, and M. Kishor et al., A Review on Friction Stir Processing of Aluminium Alloy Surface Composite, Int. J. Res. Eng., Sci. Manag., 2020, 3(4), p 103–108.

L. Zhang, X.J. Liao, S.L. Zhang et al., Effect of Powder Particle Size and Spray Parameters on the Ni/Al Reaction During Plasma Spraying of Ni-Al Composite Powders[J], J. Therm. Spray Technol., 2021, 30(1), p 181–195.

X. Wang, Z. Xing, Y. Liu et al., Composite Ceramic-Ni60 Coating Fabricated Via Supersonic Plasma Spraying, Chin. J. Phys., 2019, 61, p 72–79.

C. Shu-ying, W. Hai-dou, Ma. Guo-zheng et al., Investigation of Competing Failure Mechanism and Life of Plasma Sprayed Fe-Based Alloy Coating Under Rolling-Sliding Contact Condition, Tribol. Int., 2016, 101, p 25–32.

G. Barbezat, Advanced Thermal Spray Technology and Coating for Lightweight Engine Blocks for the Automotive Industry, Surf. Coat. Technol., 2005, 200(5–6), p 1990–1993.

V.R. Reghu, V. Shankar, and P. Ramaswamy, Challenges in Plasma Spraying of 8% Y2O3-ZrO2 Thermal Barrier Coatings on Al Alloy Automotive Piston and Influence of Vibration and Thermal Fatigue on Coating Characteristics, Mater. Today: Proc., 2018, 5(11), p 23927–23936.

C. Zhang, Z. Chu, F. Wei et al., Optimizing Process and the Properties of the Sprayed Fe-Based Metallic Glassy Coating by Plasma Spraying, Surf. Coat. Technol., 2017, 319, p 1–5.

W. Tillmann, O. Khalil, and I. Baumann, Influence of Direct Splat-Affecting Parameters on the Splat-Type Distribution, Porosity, and Density of Segmentation Cracks in Plasma-Sprayed YSZ Coatings, J. Therm. Spray Technol., 2021, 30(4), p 1015–1027.

M. Jiang, C. Ma, F. Xia et al., Application of Artificial Neural Networks to Predict the Hardness of Ni–TiN Nanocoatings Fabricated by Pulse Electrodeposition, Surf. Coat. Technol., 2016, 286, p 191–196.

L. Qiao, Y. Wu, S. Hong et al., Influence of the High-Velocity Oxygen-Fuel Spray Parameters on the Porosity and Corrosion Resistance of Iron-Based Amorphous Coatings, Surf. Coat. Technol., 2019, 366, p 296–302.

M. Liu, Z. Yu, Y. Zhang et al., Prediction and Analysis of High Velocity Oxy Fuel (HVOF) Sprayed Coating Using Artificial Neural Network, Surf. Coat. Technol., 2019, 378, p 124988.

C.S. Ramachandran, V. Balasubramanian, and P.V. Ananthapadmanabhan, Multiobjective Optimization of Atmospheric Plasma Spray Process Parameters to Deposit Yttria-Stabilized Zirconia Coatings Using Response Surface Methodology, J. Therm. Spray Technol., 2011, 20(3), p 590–607.

F.M. Elfghi, A Hubrid Statistical Approach for Modeling and Combined Application of Response Surface Methodology (RSM) and Artificial Neural Network (ANN) Based on Design of Experiment (DOE), Chem. Eng. Res. Des., 2016, 113, p 264–272.

B.-T. Lin, M.-D. Jean, and J.-H. Chou, Using Response Surface Methodology for Optimizing Deposited Partially Stabilized Zirconia in Plasma Spraying, Appl. Surf. Sci., 2007, 253, p 3254–3262.

L. Cunguang and Li. Xinmei, Application of Surface Response Method in Process Optimization of Plasma Sprayed WC-12Co Coating, Mater. Sci. Technol., 2018, 26(2), p 90–96.

L.Z. Jin et al., Process Optimization of Supersonic Plasma Transfer Arc Sprayed Aluminum Coating by Response Surface Methodology, China Surf. Eng., 2020, 33(3), p 111–121.

D. Thirumalaikumarasamy, K. Shanmugam, and V. Balasubramanian, Influences of Atmospheric Plasma Spraying Parameters on the Porosity Level of Alumina Coating on AZ31B Magnesium Alloy Using Response Surface Methodology, Prog. Nat. Sci.: Mater. Int., 2012, 22(5), p 468–479.

L. Ming, J. Zhang, Z.M. Guo et al., Process Optimization and Coating Properties of Aluminum Coating Prepared by Supersonic Plasma Powder Feeding Based on Response Surface, J. Phys: Conf. Ser., 2019, 1176(5), p 1–9.

J.G. Odhiambo, W.G. Li, Y.T. Zhao et al., Porosity and Its Significance in Plasma-Sprayed Coatings, Coatings, 2019, 9(7), p 460–479.

Ma. Guozheng, C. Shuying, He. Pengfei et al., Particle in-Flight Status and Its Influence on the Properties of Supersonic Plasma-Sprayed Fe-Based Amorphous Metallic Coatings, Surf. Coat. Technol., 2019, 358, p 394–403.

B. Jin, N. Zhang, H. Yu et al., AlxCoCrFeNiSi High Entropy Alloy Coatings with High Microhardness and Improved Wear Resistance, Surf. Coat. Technol., 2020, 402, p 126328.

G. Ma, S. Chen, and H. Wang, Micro Process and Quality Control of Plasma Spraying, Springer Press, 2022 https://doi.org/10.1007/978-981-19-2742-3

B.T. Lin, M.D. Jean, and J.H. Chou, Using Response Surface Methodology for Optimizing Deposited Partially Stabilized Zirconia in Plasma Spraying, Appl. Surf. Sci., 2007, 253(6), p 3254–3262.

S. Beg and S. Akhter, Box-Behnken Designs and Their Applications in Pharmaceutical Product Development[M]//Design of Experiments for Pharmaceutical Product Development, Springer, Singapore, 2021, p 77–85

M. Jie, D. Changguang, Y. Kun et al., Process Optimization of Atmospheric Plasma Sprayed Cr2O3 Coating by Response Surface Method, Mech. Eng. Mater., 2014, 38(6), p 100–104.

S. Sharma, Parametric Study of Abrasive Wear of Co-CrC Based Flame Sprayed Coatings by Response Surface Methodology, Tribol. Int., 2014, 75, p 39–50.

Acknowledgments

This work was supported by the Foundation of Research Project of China (50904010201)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, By., Chu, Jj., Du, Wb. et al. Optimization of Ni60A Coating Quality by Supersonic Plasma Spraying Based on Response Surface Methodology. J Therm Spray Tech 32, 1596–1610 (2023). https://doi.org/10.1007/s11666-023-01580-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01580-8