Abstract

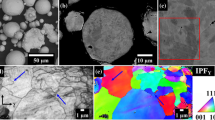

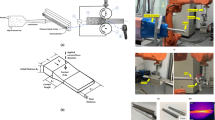

As a new member of the additive manufacturing family, cold spray provides various benefits such as a limited oxidation during deposition. Titanium alloys, being oxidation-sensitive materials, could thus benefit from this processing route. However, the high strength of these alloys implies that dense deposition is a significant challenge. Two pathways were explored to reduce porosity. The sensitivity to the different deposition parameters was first investigated. Further improvements were then obtained using in situ shot peening. Another major issue regarding the material performance is the presence of residual stresses. Usually, cold spray induces compressive residual stresses in the resulting deposits because of the shot peening effect of the solid-state particles. In contrast, the prevailing stresses are in tension in cold sprayed Ti-6Al-4V. An improved understanding of this feature, which stems from the contribution of different physical phenomena to the final stress state, would provide insights into a reduction of residual stress. This is crucial to maintain structural integrity and, in turn, consider cold spray as a viable additive manufacturing process. The in situ coating properties device allowed to measure the evolution of the residual stresses during and after deposition and to identify most influent operating parameters. The purpose of this study is to provide guidelines to control porosity and residual stresses in order to produce dense and thick Ti-6Al-4V coatings with good structural integrity.

Similar content being viewed by others

References

Z. Liu, B. He, T. Lyu, and Y. Zou, A Review on Additive Manufacturing of Titanium Alloys for Aerospace Applications: Directed Energy Deposition and Beyond Ti-6Al-4V, JOM, 2021, 73, p 1804-1818.

J.C. Williams and E.A. Starke, Progress in Structural Materials for Aerospace Systems, Acta Mater., 2003, 51(19), p 5775-5799.

C. Leyens and M. Peters Eds., Titanium and Titanium Alloys: Fundamentals and Applications, 1st ed. Wiley, New York, 2003

S. Hémery, P. Villechaise, and D. Banerjee, Microplasticity at Room Temperature in α/β Titanium Alloys, Metall. Mater. Trans. A, 2020, 51(10), p 4931-4969.

P. Cavaliere Ed., Cold-Spray Coatings, 1st ed. Springer, Cham, 2018

R.G. Maev and V. Leshchynsky Eds., Cold Gas Dynamic Spray, 1st ed. CRC Press, Boca Raton, 2016

A. Moridi Ed., Powder Consolidation Using Cold Spray, 1st ed. Springer, Cham, 2017

J. Villafuerte Ed., Modern Cold Spray: Materials, Process, and Applications, 1st ed. Springer, Cham, 2015

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkhimov, and V. Fomin, Cold Spray Technology, 1st ed. Elsevier, Amsterdam, 2007.

W.Y. Li, C. Zhang, H.T. Wang, X.P. Guo, H.L. Liao, C.J. Li, and C. Coddet, Significant Influences of Metal Reactivity and Oxide Films at Particle Surfaces on Coating Microstructure in Cold Spraying, Appl. Surf. Sci., 2007, 253(7), p 3557-3562.

W. Li, K. Yang, S. Yin, X. Yang, Y. Xu, and R. Lupoi, Solid-State Additive Manufacturing and Repairing by Cold Spraying: A Review, J. Mater. Sci. Technol., 2018, 34(3), p 440-457.

S. Yin, P. Cavaliere, B. Aldwell, R. Jenkins, H. Liao, W. Li, and R. Lupoi, Cold Spray Additive Manufacturing and Repair: Fundamentals and Applications, Addit. Manuf., 2018, 21, p 628-650.

H. Wu, X. Xie, M. Liu, C. Verdy, Y. Zhang, H. Liao, and S. Deng, Stable Layer-Building Strategy to Enhance Cold-Spray-Based Additive Manufacturing, Addit. Manuf., 2020, 35, p 101356.

A.W.Y. Tan, W. Sun, Y.P. Phang, M. Dai, I. Marinescu, Z. Dong, and E. Liu, Effects of Traverse Scanning Speed of Spray Nozzle on the Microstructure and Mechanical Properties of Cold-Sprayed Ti6Al4V Coatings, J. Therm. Spray Technol., 2017, 26(7), p 1484-1497.

S. Bagherifard, S. Monti, M.V. Zuccoli, M. Riccio, J. Kondás, and M. Guagliano, Cold Spray Deposition for Additive Manufacturing of Freeform Structural Components Compared to Selective Laser Melting, Mater. Sci. Eng. A, 2018, 721, p 339-350.

C.J. Huang, H.J. Wu, Y.C. Xie, W.Y. Li, C. Verdy, M.P. Planche, H.L. Liao, and G. Montavon, Advanced Brass-Based Composites via Cold-Spray Additive-Manufacturing and Its Potential in Component Repairing, Surf. Coat. Technol., 2019, 371, p 211-223.

V. Champagne and D. Helfritch, The Unique Abilities of Cold Spray Deposition, Int. Mater. Rev., 2016, 61(7), p 437-455.

S. Singh, H. Singh, S. Chaudhary, and R.K. Buddu, Effect of Substrate Surface Roughness on Properties of Cold-Sprayed Copper Coatings on SS316L Steel, Surf. Coat. Technol., 2020, 389, p 125619.

P. Cavaliere, A. Silvello, N. Cinca, H. Canales, S. Dosta, I. Garcia Cano, and J.M. Guilemany, Microstructural and Fatigue Behavior of Cold Sprayed Ni-Based Superalloys Coatings, Surf. Coat. Technol., 2017, 324, p 390-402.

D. Goldbaum, J.M. Shockley, R.R. Chromik, A. Rezaeian, S. Yue, J.G. Legoux, and E. Irissou, The Effect of Deposition Conditions on Adhesion Strength of Ti and Ti6Al4V Cold Spray Splats, J. Therm. Spray Technol., 2012, 21(2), p 288-303.

A.M. Birt, V.K. Champagne, R.D. Sisson, and D. Apelian, Microstructural Analysis of Cold-Sprayed Ti-6Al-4V at the Micro- and Nano-scale, J. Therm. Spray Technol., 2015, 24(7), p 1277-1288.

V.S. Bhattiprolu, K.W. Johnson, O.C. Ozdemir, and G.A. Crawford, Influence of Feedstock Powder and Cold Spray Processing Parameters on Microstructure and Mechanical Properties of Ti-6Al-4V Cold Spray Depositions, Surf. Coat. Technol., 2018, 335, p 1-12.

V.N.V. Munagala, V. Akinyi, P. Vo, and R.R. Chromik, Influence of Powder Morphology and Microstructure on the Cold Spray and Mechanical Properties of Ti6Al4V Coatings, J. Therm. Spray Technol., 2018, 27(5), p 827-842.

W. Wong, E. Irissou, A.N. Ryabinin, J.G. Legoux, and S. Yue, Influence of Helium and Nitrogen Gases on the Properties of Cold Gas Dynamic Sprayed Pure Titanium Coatings, J. Therm. Spray Technol., 2011, 20(1-2), p 213-226.

X.T. Luo, Y.K. Wei, Y. Wang, and C.J. Li, Microstructure and Mechanical Property of Ti and Ti6Al4V Prepared by an In-Situ Shot Peening Assisted Cold Spraying, Mater. Des., 2015, 85, p 527-533.

H. Zhou, C. Li, G. Ji, S. Fu, H. Yang, X. Luo, G. Yang, and C. Li, Local Microstructure Inhomogeneity and Gas Temperature Effect in In-Situ Shot-Peening Assisted Cold-Sprayed Ti-6Al-4V Coating, J. Alloys Compd., 2018, 766, p 694-704.

X.T. Luo, M.L. Yao, N. Ma, M. Takahashi, and C.J. Li, Deposition Behavior, Microstructure and Mechanical Properties of an in-Situ Micro-Forging Assisted Cold Spray Enabled Additively Manufactured Inconel 718 Alloy, Mater. Des., 2018, 155, p 384-395.

S. Rech, A. Trentin, S. Vezzù, J.G. Legoux, E. Irissou, and M. Guagliano, Influence of Pre-Heated Al 6061 Substrate Temperature on the Residual Stresses of Multipass Al Coatings Deposited by Cold Spray, J. Therm. Spray Technol., 2011, 20(1-2), p 243-251.

T. Suhonen, T. Varis, S. Dosta, M. Torrell, and J.M. Guilemany, Residual Stress Development in Cold Sprayed Al, Cu and Ti Coatings, Acta Mater., 2013, 61(17), p 6329-6337.

V. Luzin, K. Spencer, and M.X. Zhang, Residual Stress and Thermo-Mechanical Properties of Cold Spray Metal Coatings, Acta Mater., 2011, 59(3), p 1259-1270.

K. Spencer, V. Luzin, N. Matthews, and M.X. Zhang, Residual Stresses in Cold Spray Al Coatings: The Effect of Alloying and of Process Parameters, Surf. Coat. Technol., 2012, 206(19-20), p 4249-4255.

D. Boruah, X. Zhang, and M. Doré, Theoretical Prediction of Residual Stresses Induced by Cold Spray with Experimental Validation, Multidiscip. Model. Mater. Struct., 2019, 15(3), p 599-661.

S. Kuroda and T.W. Clyne, The Quenching Stress in Thermally Sprayed Coatings, Thin Solid Films, 1991, 200(1), p 49-66.

M.A. Meyers, Y.B. Xu, Q. Xue, M.T. Pérez-Prado, and T.R. McNelley, Microstructural Evolution in Adiabatic Shear Localization in Stainless Steel, Acta Mater., 2003, 51(5), p 1307-1325.

D. Boruah, B. Ahmad, T.L. Lee, S. Kabra, A.K. Syed, P. McNutt, M. Doré, and X. Zhang, Evaluation of Residual Stresses Induced by Cold Spraying of Ti-6Al-4V on Ti-6Al-4V Substrates, Surf. Coat. Technol., 2019, 374, p 591-602.

A. Bhowmik, A.W.T. Tan, W. Sun, Z. Wei, I. Marinescu, and E. Liu, On the Heat-Treatment Induced Evolution of Residual Stress and Remarkable Enhancement of Adhesion Strength of Cold Sprayed Ti-6Al-4V Coatings, Results Mater., 2020, 7, p 100119.

V. Luzin, O. Kirstein, S.H. Zahiri, and D. Fraser, Residual Stress Buildup in Ti Components Produced by Cold Spray Additive Manufacturing (CSAM), J. Therm. Spray Technol., 2020, 29, p 1498-1507.

A. Vargas-Uscategui, P.C. King, M.J. Styles, M. Saleh, V. Luzin, and K. Thorogood, Residual Stresses in Cold Spray Additively Manufactured Hollow Titanium Cylinders, J. Therm. Spray Technol., 2020, 29(6), p 1508-1524.

D. Brice, R.M. Rahimi, and D.F. Bahr, Hardening Particulate Ti Media Through Controlled Oxidation, Metall. Mater. Trans. A, 2019, 50(9), p 3980-3984.

J. Schindelin, I. Arganda-Carreras, E. Frise, V. Kaynig, M. Longair, T. Pietzsch, and A. Cardona, Fiji: An Open-Source Platform for Biological-Image Analysis, Nat. Methods, 2012, 9(7), p 676-682.

M. Benabdi and A.A. Roche, Mechanical Properties of Thin and Thick Coatings Applied to Various Substrates. Part I. An Elastic Analysis of Residual Stresses within Coating Materials, J. Adhes. Sci. Technol., 1997, 11(2), p 281-299.

A. Brenner and S. Senderoff, Calculation of Stress in Electrodeposits from the Curvature of a Plated Strip, J. Res. Natl. Bur. Stand., 1949, 42(RP1954), p 105-123.

T.W. Clyne and S.C. Gill, Residual Stresses in Thermal Spray Coatings and Their Effect on Interfacial Adhesion: A Review of Recent Work, J. Therm. Spray Technol., 1996, 5(4), p 401-418.

G.G. Stoney, The Tension of Metallic Films Deposited by Electrolysis, Proc. R. Soc. Math. Phys. Eng. Sci., 1909, 82(553), p 172-175.

M. Mutter, G. Mauer, R. Mücke, O. Guillon, and R. Vaßen, Correlation of Splat Morphologies with Porosity and Residual Stress in Plasma-Sprayed YSZ Coatings, Surf. Coat. Technol., 2017, 318, p 157-169.

T. Sugahara, D.A.P. Reis, C. de Moura Neto, M.J.R. Barboza, E.A.C. Perez, F.P. Neto, and A.C.O. Hirschmann, The Effect of Widmanstätten and Equiaxed Microstructures of Ti-6Al-4V on the Oxidation Rate and Creep Behavior, Mater. Sci. Forum, 2010, 636, p 657-662.

C.M. Kay and J. Karthikeyan Eds., High Pressure Cold Spray: Principles and Applications, 1st ed. ASM International, Materials Park, 2016

H. Conrad, Effect of Interstitial Solutes on the Strength and Ductility of Titanium, Prog. Mater. Sci., 1981, 26(2-4), p 123-403.

C. Chen, Y. Xie, R. Huang, S. Deng, Z. Ren, and H. Liao, On the role of oxide film’s cleaning effect into the metallurgical bonding during cold spray, Mater. Lett., 2018, 210, p 199-202.

R. Rixain, Optimisation du dimensionnement de tuyères de projection de type Cold-Spray, Master thesis, Université de Poitiers, 2018 (in French)

L. Kovacs, Analyse de l’état thermocinétique de particules dans leur écoulement, Master thesis, Université d’Orléans, 2019 (in French)

E. Raletz, G. Ezo’o, S. Germain, M. Vardelle, and G. Mariaux, Optimisation de La Distance de Tir En Projection Cold Spray, Méc. Ind., 2011, 12(6), p 533-537.

M.R. Rokni, S.R. Nutt, C.A. Widener, V.K. Champagne, and R.H. Hrabe, Review of Relationship Between Particle Deformation, Coating Microstructure, and Properties in High-Pressure Cold Spray, J. Therm. Spray Technol., 2017, 26(6), p 1308-1355.

A. Malachowska, Analysis of the Cold Gas Spraying Process and Determination of Selected Properties of Metallic Coatings on Polymers, Ph.D. thesis, Université de Limoges, 2018

R. Lupoi and W. O’Neill, Powder Stream Characteristics in Cold Spray Nozzles, Surf. Coat. Technol., 2011, 206(6), p 1069-1076.

B. Moreno-Murguia, A.G. Mora-Garcia, H. Canales-Siller, A.L. Giraldo-Betancur, D.G. Espinosa-Arbelaez, and J. Muñoz-Saldaña, Influence of Stand-off Distance and Pressure in Copper Coatings Deposition Efficiency and Particle Velocity, Surf. Coat. Technol., 2022, 430, p 127986.

S. Rech, A. Trentin, S. Vezzù, J.G. Legoux, E. Irissou, and M. Guagliano, Influence of Pre-Heated Al 6061 Substrate Temperature on the Residual Stresses of Multipass Al Coatings Deposited by Cold Spray, J. Therm. Spray Technol., 2010, 20, p 243-251.

M.J. Shepard, P.R. Smith, and M.S. Amer, Introduction of Compressive Residual Stresses in Ti-6Al-4V Simulated Airfoils via Laser Shock Processing, J. Mater. Eng. Perform., 2001, 10(6), p 670-678.

O. Karpenko, S. Oterkus, and E. Oterkus, Investigating the Influence of Residual Stresses on Fatigue Crack Growth for Additively Manufactured Titanium Alloy Ti6Al4V by Using Peridynamics, Int. J. Fatigue, 2022, 155, 106624.

Acknowledgments

Pprime Institute gratefully acknowledges “Contrat de Plan Etat – Région Nouvelle-Aquitaine” (CPER) as well as the “Fonds Européen de Développement Régional” (FEDER) for their financial support to the reported work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lett, S., Quet, A., Hémery, S. et al. Residual Stresses Development during Cold Spraying of Ti-6Al-4V Combined with In Situ Shot Peening. J Therm Spray Tech 32, 1018–1032 (2023). https://doi.org/10.1007/s11666-022-01514-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01514-w