Abstract

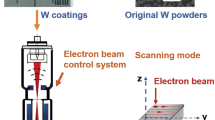

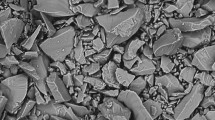

Boron carbide (B4C) is considered an ideal material for plasma-facing materials (PFMs) in nuclear fusion, due to a combination of excellent properties: high elastic modulus, high chemical stability, low Z and high melting point. In this paper, B4C coatings were fabricated onto tungsten (W) substrates using atmospheric plasma spraying (APS). The powder feed rate significantly affects the coating quality. The effects of different powder feed rates on the properties of sprayed coatings including thickness, porosity, and adhesion strength were investigated. The particle temperature and the particle velocity were measured by the diagnostic system DPV evolution. Phase evolution and microstructure were characterized by x-ray diffraction (XRD) and scanning electron microscopy (SEM). XRD analysis showed that the main phase composition of the coating did not change compared with the initial B4C powder, the surface of the B4C coating was oxidized and formed B2O3. It has been demonstrated that the adhesion strength of the coating increases and then decreases with the increase of powder feed rate. Under the optimal powder feed rate of 1 g/min, the optimal adhesion strength of the coating is 11.38 MPa.

Similar content being viewed by others

References

J. Ongena and Y. Ogawa, Nuclear Fusion: Status Report and Future Prospects, Energy Policy, 2016, 96, p 770-778. https://doi.org/10.1016/j.enpol.2016.05.037

A. Marco, A.J. Garrido, S. Coda, and I. Garrido, A Variable Structure Control Scheme Proposal for the Tokamak à Configuration Variable, Complexity, 2019, 24, p 1-10.

J. Linke, J. Du, T. Loewenhoff, G. Pintsuk, B. Spilker, I. Steudel, and M. Wirtz, Challenges for Plasma-Facing Components in Nuclear Fusion, Matter. Radiat. Extrem., 2019, 4(5), p 2-18. https://doi.org/10.1063/1.5090100

F. Wang, G.N. Luo, and J. Huang, Transient and Steady State High Heat Load Testing of Atmospheric Plasma Sprayed Tungsten, Fusion Eng. Des., 2020, 2020(152), p 111-427. https://doi.org/10.1016/j.fusengdes.2019.111427

J. Hu, G. Zuo, L. Wang, R. Ding, Y. Yu, Y. Zhang, and W. Xu, Brief Review of the Interactions between Plasma and Walls in Magnetic Controlled Fusion Devices, J. Univ. Sci. Technol. China, 2020, 50(9), p 1193-1216.

J.N. Brooks, L. El-Guebaly, A. Hassanein, and T. Sizyuk, Plasma-Facing Material Alternatives to Tungsten, Nucl. Fusion, IOP Publishing, 2015, 55(4), p 1-7.

X. Wu, X. Li, Y. Zhang, Y. Xu, W. Liu, Z. Xie, R. Liu, G.N. Luo, X. Liu, and C.S. Liu, Recent Advances on Interface Design and Preparation of Advanced Tungsten Materials for Plasma Facing Materials, J. Fusion Energy, 2020, 39(6), p 342-354. https://doi.org/10.1007/s10894-020-00271-4

V. Philipps, Tungsten as Material for Plasma-Facing Components in Fusion Devices, J. Nucl. Mater., 2011, 415(1 SUPPL), p S2-s9. https://doi.org/10.1016/j.jnucmat.2011.01.110

M. Shimada and Y. Hirooka, Actively Convected Liquid Metal Divertor, Nucl. Fusion, 2014, 54(12), p 1-7.

J.E. Döring, R. Vaßen, J. Linke, and D. Stöver, Properties of Plasma Sprayed Boron Carbide Protective Coatings for the First Wall in Fusion Experiments, J. Nucl. Mater., 2002, 307-311(1 SUPPL.), p 121-125.

O.I. Buzhinskij and Y.M. Semenets, Thick Boron Carbide Coatings for Protection of Tokamak First Wall and Divertor, Fusion Eng. Des., 1999, 45(4), p 343-360.

J. Matějíček, P. Chráska, and J. Linke, Thermal Spray Coatings for Fusion Applications - Review, J. Therm. Spray Technol., 2007, 16(1), p 64-83.

L.B. Begrambekov, A.V. Grunin, and Y.A. Sadovskiy, Behavior of B4C Coating on Tungsten under Exposition on T-10 Tokamak Plasma, J. Phys. Conf. Ser., 2019, 1281(1), p 1-4.

Q. Zhou, P. Zhao, Q. Guo, L. Li, and Y. Meng, Effect of Spray Distance to the Adhesion Strength of Inductively Coupled Plasma Sprayed B4C/W Coating, Trans. China Electrotech. Soc., 2019, 34(6), p 1345-1350.

E. Azizov, V. Barsuk, L. Begrambekov, O. Buzhinsky, A. Evsin, A. Gordeev, A. Grunin, N. Klimov, V. Kurnaev, I. Mazul, V. Otroshchenko, A. Putric, Y. Sadovskiy, P. Shigin, S. Vergazov, and A. Zakharov, Boron Carbide (B4C) Coating, Depos. Test. J. Nucl. Mater., 2015, 463, p 792-795. https://doi.org/10.1016/j.jnucmat.2015.01.015

P.K. Purnapu Rupa, P. Sharma, R.M. Mohanty, and K. Balasubramanlan, Microstructure and Phase Composition of Composite Coatings Formed by Plasma Spraying of ZrO 2and B4C Powders, J. Therm. Spray Technol., 2010, 19(4), p 816-823.

Y. Zeng, C. Ding, and S.W. Lee, Young’s Modulus and Residual Stress of Plasma-Sprayed Boron Carbide Coatings, J. Eur. Ceram. Soc., 2001, 21(1), p 87-91.

Y. Zeng, S.W. Lee, and C. Ding, Study on Plasma Sprayed Boron Carbide Coating, J. Therm. Spray Technol., 2002, 11(1), p 129-133.

M.R. Mrdak, Influence of a Powder Feed Rate on the Properties of the Plasma Sprayed Chromium Carbide-25% Nickel Chromium Coating, Vojnoteh. Glas., 2014, 62(2), p 7-26.

S.A. Sadeghi-Fadaki, K. Zangeneh-Madar, and Z. Valefi, The Adhesion Strength and Indentation Toughness of Plasma-Sprayed Yttria Stabilized Zirconia Coatings, Surf. Coatings Technol., 2010, 204(14), p 2136-2141.

B. Swain and A. Behera, Effect of Powder Feed Rate on Adhesion Strength and Microhardness of APS NiTi Coating: A Microstructural Investigation, Surf. Topogr. Metrol. Prop, 2021, 9(2), p 1-7.

P. Nunthavarawong, N. Sacks, and I. Botef, Effect of Powder Feed Rate on the Mechanical Properties of WC-5 Wt.%Ni Coatings Deposited Using Low Pressure Cold Spray, Int. J. Refract. Met. Hard Mater., 2016, 61, p 230-237. https://doi.org/10.1016/j.ijrmhm.2016.10.001

M. Mrdak, B. Medjo, D. Veljić, M. Arsić, and M. Rakin, The Influence of Powder Feed Rate on Mechanical Properties of Atmospheric Plasma Spray (APS) Al-12Si Coating, Rev. Adv. Mater. Sci., 2019, 58(1), p 75-81.

G. Mauer, R. Vaßen, S. Zimmermann, T. Biermordt, M. Heinrich, J.L. Marques, K. Landes, and J. Schein, Investigation and Comparison of In-Flight Particle Velocity during the Plasma-Spray Process as Measured by Laser Doppler Anemometry and DPV-2000, J. Therm. Spray Technol., 2013, 22(6), p 892-900.

G. Mauer, R. Vaßen, and D. Stöver, Comparison and Applications of DPV-2000 and Accuraspray-G3 Diagnostic Systems, J. Therm. Spray Technol., 2007, 16(3), p 414-424.

J. Colmenares-Angulo, K. Shinoda, T. Wentz, W. Zhang, Y. Tan, and S. Sampath, On the Response of Different Particle State Sensors to Deliberate Process Variations, J. Therm. Spray Technol., 2011, 20(5), p 1035-1048.

N. Pulido-González, S. García-Rodríguez, M. Campo, J. Rams, and B. Torres, Application of DOE and ANOVA in Optimization of HVOF Spraying Parameters in the Development of New Ti Coatings, J. Therm. Spray Technol., 2020, 29(3), p 384-399.

C.S. Ramachandran, V. Balasubramanian, and P.V. Ananthapadmanabhan, Multiobjective Optimization of Atmospheric Plasma Spray Process Parameters to Deposit Yttria-Stabilized Zirconia Coatings Using Response Surface Methodology, J. Therm. Spray Technol., 2011, 20(3), p 590-607.

J. Kitamura, S. Usuba, Y. Kakudate, H. Yokoi, K. Yamamoto, A. Tanaka, and S. Fujiwara, Structure and Mechanical Properties of Boron Carbide Coatings Formed by Electromagnetically Accelerated Plasma Spraying, Diam. Relat. Mater., 2003, 12(10-11), p 1891-1896.

Q.H.F. Rebelo, C.S. Ferreira, P.L. Santos, J.A. Bonacin, R.R. Passos, L.A. Pocrifka, and M.M.S. Paula, Synthesis and Characterization of a Nanocomposite NiO/SiO2 from a Sustainable Source of SiO2, Part. Sci. Technol., 2019, 37(8), p 907-911.

A.M. Ali and R. Najmy, Structural, Optical and Photocatalytic Properties of NiO-SiO2 Nanocomposites Prepared by Sol-Gel Technique, Catal. Today, 2013, 208, p 2-6.

L. Li, G.H. Ni, Q.J. Guo, Q.F. Lin, P. Zhao, and J.L. Cheng, Spheroidization of Silica Powders by Radio Frequency Inductively Coupled Plasma with Ar-H2 and Ar-N2 as the Sheath Gases at Atmospheric Pressure, Int. J. Miner. Metall. Mater., 2017, 24(9), p 1067-1074.

C.M. Lin, H.L. Tsai, and C. Yang, Effects of Microstructure and Properties on Parameter Optimization of Boron Carbide Coatings Prepared Using a Vacuum Plasma-Spraying Process, Surf. Coatings Technol., 2012, 206(10), p 2673-2681. https://doi.org/10.1016/j.surfcoat.2011.11.023

H. Chen, J. Yang, Q. Shuai, J. Li, Q. Ouyang, and S. Zhang, In-Situ Doping B4C Nanoparticles in PAN Precursors for Preparing High Modulus PAN-Based Carbon Fibers with Boron Catalytic Graphitization, Compos. Sci. Technol., 2020, 200(September), p 2-10.

Y. Wang, Q. Liu, B. Zhang, J. Ding, H. Zhang, Y. Jin, Z. Zhong, W. Wang, and F. Ye, Effect of Pretreatment Process of B4C Powder on the Surface Properties and Freeze-Cast Porous Ceramics, Mater. Chem. Phys., 2020, 251(February), p 2-9.

G. Zhuo, L. Su, K. Jiang, and J. Yang, Effect of Spraying Power on Oxidation Resistance of MoSi2-ZrB2 Coating for Nb-Si Based Alloy Prepared by Atmospheric Plasma, Mater. Artic., 2020, 13(22), p 5060.

D.S. Lee, S. Yun, J.W. Han, M.Y. Song, Y.G. Kim, J.K. Lee, J. Choi, S. Chang, S. Hong, and J.H. Kim, Microstructural Evolution and Mechanical Properties of Atmospheric Plasma Sprayed Y2O3 Coating with State of In-Flight Particle, Ceram. Int., 2021, 47(3), p 3853-3866. https://doi.org/10.1016/j.ceramint.2020.09.246

Acknowledgment

This work was jointly supported by China Baowu Low Carbon Metallurgical Innovation Foundation. We thank Prof. Huang Jianjun’s group from ShenZhen University for their valuable help and suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jin, X., Zhao, P., Zeng, M. et al. Effect of Powder Feed Rate on Mechanical Properties of Boron Carbide Coatings by Atmospheric Plasma Spraying (APS). J Therm Spray Tech 32, 162–174 (2023). https://doi.org/10.1007/s11666-022-01467-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01467-0