Abstract

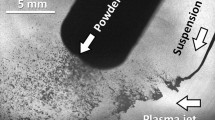

Environmental barrier coatings (EBCs) protect SiC/SiC ceramic matrix composites from steam oxidation. Yb2Si2O7 is a promising ceramic material for the top coating of the EBCs. However, thermal shock and foreign object debris can cause cracks on the surface of an EBC, thereby reducing its ability to overcome environmental barriers. It has been found that an EBC can be strengthened by adding SiC to its top coating; this addition heals the cracks present on the EBC when subjected to high-temperature oxidation. In this study, the SiC contents of Yb2Si2O7 coatings prepared using atmospheric plasma spraying (APS) were evaluated to identify the structure and composition of the coatings. The results of crack-healing tests show that the Yb2Si2O7/SiC granulated powder could retain SiC particles in the coatings after the spraying, whereas in Yb2Si2O7/SiC mixed powder, the SiC particles evaporated during APS, indicating that Yb2Si2O7/SiC granulated powder can be used as the feedstock powder in self-healing EBCs. The time-dependent changes in surface crack closure and Yb2Si2O7/SiC granular powder coating remediation caused due to high-temperature oxidation were also evaluated. It was found that the reliability of self-healing EBCs could be improved by appropriately controlling the particle size and SiC content in the coatings.

Similar content being viewed by others

References

F. Christin, Design, Fabrication, and Application of Thermostructural Composites (TSC) like C/C, C/SiC, and SiC/SiC Composites, Adv. Eng. Mater., 2002, 4(12), p 903-912. https://doi.org/10.1002/adem.200290001

T. Nakamura, K. Imanari, K. Shinohara and M. Ishizaki, Development of CMC Turbine Parts for Aero Engines, IHI Eng. Rev., 2014, 47, p 29-32. (in Japanese)

H.V. Pham, Y. Nagae, M. Kurata, D. Bottomley and K. Furumoto, Oxidation Kinetics of Silicon Carbide in Steam at Temperature Range of 1400 to 1800 Studied by Laser Heating, J. Nuc. Mater., 2020, 529, p 151939. https://doi.org/10.1016/j.jnucmat.2019.151939

K.L. More, P.F. Tortorelli, M.K. Ferber and J.R. Keiser, Observations of Accelerated Silicon Carbide Recession by Oxidation at High Water-Vapor Pressures, J. Am. Ceram. Soc., 2000, 83(1), p 211-213. https://doi.org/10.1111/j.1151-2916.2000.tb01172.x

I. Spitsberg and J. Steibel, Thermal and Environmental Barrier Coatings for SiC/SiC CMCs in Aircraft Engine Applications, Int. J. Appl. Ceram. Tech., 2004, 1(4), p 291-301.

N. Al Nasiri, N. Patra, M. Pezoldt, J. Colas and W. Lee, Investigation of a Single-Layer EBC Deposited on SiC/SiC CMCs: Processing and Corrosion Behaviour in High-Temperature Steam, J. Eur. Ceram. Soc., 2019, 39(8), p 2703-2711.

K.N. Lee, D.S. Fox, J.I. Eldridge, D. Zhu, R.C. Robinson, N.P. Bansal and R.A. Miller, Upper Temperature Limit of Environmental Barrier Coatings Based on Mullite and BSAS, J. Am. Ceram. Soc., 2003, 86(8), p 1299–1306. https://doi.org/10.1111/j.1151-2916.2003.tb03466.x

S. Ramasamy, S.N. Tewari, K.N. Lee, R.T. Bhatt and D.S. Fox, Environmental Durability of Slurry Based Mullite-Gadolinium Silicate EBCs on Silicon Carbide, J. Eur. Ceram. Soc., 2011, 31(6), p 1123-1130.

Y. Xu, X. Hu, F. Xu and K. Li, Rare Earth Silicate Environmental Barrier Coatings: Present Status and Prospective, Ceram. Int., 2017, 43(8), p 5847-5855. https://doi.org/10.1016/j.ceramint.2017.01.153

N. Al Nasiri, N. Patra, D. Horlait, D.D. Jayaseelan and W.E. Lee, Thermal Properties of Rare-Earth Monosilicates for EBC on Si-Based Ceramic Composites, J. Am. Ceram. Soc., 2016, 99(2), p 589-659. https://doi.org/10.1111/jace.13982

N. Al Nasiri, N. Patra, D. Jayaseelan and W. Lee, Water Vapour Corrosion of Rare Earth Monosilicates for Environmental Barrier Coating Application, Ceram. Int, 2017, 43(10), p 7393-7400. https://doi.org/10.1016/j.ceramint.2017.02.123

J. Han, Y. Wang, R. Liu and Y. Cao, Thermal Shock Behavior of Mixed Ytterbium Disilicates and Ytterbium Monosilicates Composite Environmental Barrier Coatings, Surf. Coat. Technol., 2018, 352, p 348-353.

A.J. Fernándezg, R. Liu and Y. Cao, Thermal Expansion of Rare-Earth Pyrosilicates, J. Am. Ceram. Soc., 2013, 96(7), p 2298-2305.

Z. Tian, L. Zheng, Z. Li, J. Li and J. Wang, Exploration of the Low Thermal Conductivities of γ-Y2Si2O7, β- Y2Si2O7, β-Yb2Si2O7, and β-Lu2Si2O7 as Novel Environmental Barrier Coating Candidates, J. Eur. Ceram. Soc., 2016, 36(11), p 2813-2823.

N. Rohbeck, P. Morrell and P. Xiao, Degradation of Ytterbium Disilicate Environmental Barrier Coatings in High Temperature Steam Atmosphere, J. Eur. Ceram. Soc., 2019, 39(10), p 3153-3163.

B. Zou, Z.S. Khan, X. Fan, W. Huang, L. Gu, Y. Wang, J. Xu, S. Tao, K. Yang and H. Ma, X. Cao, A New Double Layer Oxidation Resistant Coating Based on Er2SiO5/LaMgAl11O19 Deposited on C/SiC Composites by Atmospheric Plasma Spraying, Surf. Coat. Technol., 2013, 219, p 101-108.

B.T. Richards, K.A. Young, F. de Francqueville, S. Sehr, M.R. Begley and H.N. Wadley, Response of Ytterbium Disilicate-Silicon Environmental Barrier Coatings to Thermal Cycling in Water Vapor, Acta Mater., 2013, 106, p 1-14. https://doi.org/10.1016/j.actamat.2015.12.053

P. Chen, L. Pan, P. Xiao, Z. Li, D. Pu, J. Li, L. Pang and Y. Li, Microstructure and Anti-oxidation Properties of Yb2Si2O7/SiC Bilayer Coating for C/SiC Composites, Ceram. Int., 2019, 45(18), p 24221-24229. https://doi.org/10.1016/j.ceramint.2019.08.132

X. Chen, R. Wang, N. Yao, A. Evans, J. Hutchinson and R. Bruce, Foreign Object Damage in a Thermal Barrier System: Mechanisms and Simulations, Mat. Sci. Eng. A, 2003, 352(1-2), p 221-231.

T. Osada, K. Kamoda, M. Mitome, T. Hara, T. Abe, Y. Tamagawa, W. Nakao and T. Ohmura, A Novel Design Approach for Self-Crack-Healing Structural Ceramics With 3D Networks of Healing Activator, Sci. Rep., 2017, 7, p 1-9.

K. Ando, K. Furusawa, K. Takahashi and S. Sato, Crack-Healing Ability of Structural Ceramics and a New Methodology To Guarantee the Structural Integrity Using the Ability and Proof-Test, J. Eur. Ceram. Soc., 2005, 25(5), p 549-558.

S.T. Nguyen, T. Nakayama, H. Suematsu, T. Suzuki, L. He, H.B. Cho and K. Niihara, Strength Improvement and Purification of Yb2Si2O7-SiC Nanocomposites by Surface Oxidation Treatment, J. Am. Ceram. Soc., 2017, 100(7), p 3122-3131. https://doi.org/10.1111/jace.14831

Y. Chen, Y. Lu, Q. Ye and Y. Wang, A Self-Healing Environmental Barrier Coating: TiSi2-doped Y2Si2O7/Barium Strontium Aluminosilicate Coating, Surf. Coat. Technol., 2016, 307, p 436-440.

S.T. Nguyen, T. Nakayama, H. Suematsu, H. Iwasawa, T. Suzuki, Y. Otsuka, L. He, T. Takahashi and K. Niihara, Self-Healing Behavior and Strength Recovery of Ytterbium Disilicate Ceramic Reinforced With Silicon Carbide Nanofillers, J. Eur. Ceram. Soc., 2019, 39(10), p 3139-3152.

S.T. Nguyen, T. Takahashi, A. Okawa, H. Suematsu, K. Niihara and T. Nakayama, Improving Self-Healing Ability and Flexural Strength of Ytterbium Silicate-Based Nanocomposites With Silicon Carbide Nanoparticulates and Whiskers, J. Ceram. Soc. Jpn., 2021, 129(4), p 209-216.

B.T. Richards and H.N. Wadley, Plasma Spray Deposition of Tri-Layer Environmental Barrier Coatings, J. Eur. Ceram. Soc., 2014, 34(12), p 3069-3083.

R. Yanaoka, Y. Ichikawa, K. Ogawa, T. Masuda and K. Sato, Fundamental Study of Suspension Plasma Sprayed Silicate Coatings, Mater. Trans., 2020, 61(7), p 1390-1395.

E. Garcia, H. Lee and S. Sampath, Phase and Microstructure Evolution in Plasma Sprayed Yb2Si2O7 Coatings, J. Eur. Ceram. Soc., 2019, 39(4), p 1477-1486.

X. Jie, L. Qiaomu, L. Jingchen, G. Hongbo and X. Huibin, Microstructure and High-Temperature Oxidation Behavior of Plasma-Sprayed Si/Yb2SiO5 Environmental Barrier Coatings, Chinese J. Aeronaut., 2019, 32(8), p 1994-1999.

T. Kitahara, R. Yanaoka, Y. Ichikawa, K. Ogawa, T. Masuda and K. Sato, Control of Suspension Plasma Sprayed Yb Silicate Coatings by Means of SiO2 Rich Suspension, J. Jap. Therm. Spray Soc., 2020, 57(1), p 20-26. ((in Japanese))

K. Mitani, H. Saito, Y. Ichikawa, K. Ogawa, T. Masuda and N. Okamoto, Effect of SiC Content and Particle Size on the Self-Healing Property of Plasma-Sprayed Environmental Barrier Coatings, J. Jpn. Therm. Spray Soc., 2022, 59(1), p 27–32. (in Japanese)

R.P. Haggerty, P. Sarin, Z.D. Apostolov, P.E. Driemeyer and W.M. Kriven, Thermal Expansion of HfO2 and ZrO2, J. Am. Ceram. Soc., 2014, 97(7), p 2213-2222.

S. Wang, Y. Lu and Y. Chen, Synthesis of Single-Phase β-Yb2Si2O7 and Properties of Its Sintered Bulk, Int. J. Appl. Ceram. Technol., 2015, 12(6), p 1140-1147.

Acknowledgements

This research was supported by the EBC working group of the Japan Thermal Spray Society. The authors would like to express the deepest appreciation to the members and people involved in the working group.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kitahara, T., Mitani, K., Saito, H. et al. Improvement in the Self-healing Property of Plasma-Sprayed Environmental Barrier Coatings by SiC Addition. J Therm Spray Tech 31, 2314–2326 (2022). https://doi.org/10.1007/s11666-022-01441-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01441-w