Abstract

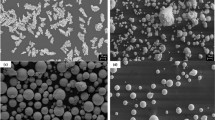

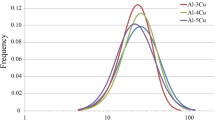

Abradable coatings are mostly sprayed using melting-associated thermal spray methods, which come with some drawbacks limiting their usage. While the manufacturing of these coatings using cold spray (CS) can potentially offer considerable advantages, there has been limited successes in depositing such coatings using this techniqe. In this study, the deposition mechanisms of Cu-hBN mixtures used as an abradable material model were studied using the pulsed gas dynamic spray process (PGDS). Coating microstructure analysis using electron channeling contrast imaging method, Raman spectroscopy, microhardness and fracture surface analyses were performed. Three sets of coatings were sprayed with 0, 9.8 and 18.6 vol.% hBN and balanced Cu powder mixtures. Averages of approximately 9 and 16 vol.% hBN phase was retained in the deposited coatings with a fine distribution of hBN at particle boundaries while deposition of these powder mixtures was unsuccessful using CS (using similar spray parameters and slightly lower pressure). It has been found that the higher temperature of particles in the PGDS as well as the “powder packets” structure typical of PGDS is due to the pulsatile nature facilitate coating deposition while an increase in the hBN phase significantly decreases the process DE. Vortex-like structures were observed in the coatings with high hBN phase content and attributed to the nature of the solid lubricant phase and decreased DE. It was shown that the hBN phase was trapped either at the inter-branching space of the dendritic feedstock powder Cu particles (demonstrating the importance of the feedstock powder selection) or at inter-particle boundaries due to the shock-induced acceleration of packets of particles, revealing the role of the process physics in the deposition of this material.

Graphical Abstract

Similar content being viewed by others

References

B. Zhang and M. Marshall, Investigating Material Removal Mechanism of Al-Si Base Abradable Coating in labyrinth Seal System, Wear, 2019, 426–427, p 239–249. https://doi.org/10.1016/j.wear.2019.01.034

Z. Wang, L. Du, H. Lan, C. Huang and W. Zhang, A Novel Technology of Sol Precursor Plasma Spraying to Obtain the Ceramic Matrix abradable Sealing Coating, Mater. Lett., 2019, 253, p 226–229. https://doi.org/10.1016/j.matlet.2019.05.079

L. Schuster, Abradable Composition and seal of An axial-Flow Turbomachine Compressor Casing, Google Patents, 2018.

Y. Kimura, T. Wakabayashi, K. Okada, T. Wada and H. Nishikawa, Boron Nitride as a Lubricant Additive, Wear, 1999, 232, p 199–206. https://doi.org/10.1016/S0043-1648(99)00146-5

H.I. Faraoun, T. Grosdidier, J.L. Seichepine, D. Goran, H. Aourag, C. Coddet, J. Zwick and N. Hopkins, Improvement of Thermally sprayed Abradable Coating by Microstructure Control, Surf. Coat. Technol., 2006, 201, p 2303–2312. https://doi.org/10.1016/j.surfcoat.2006.03.047

S. Martawirya, R.D. Ramdan, B. Prawara, E. Martides, R. Wirawan, B. Widyanto, R. Suratman and I. Pratiwi, Mechanical Properties, Microstructure and Wear characteristic of Abradable Material Coated by HVOF with Variation Of Surface Treatment and Spray Distance, AIP Conf. Proc., 2020, 2262, p 060010. https://doi.org/10.1063/5.0017744

J. Ziegelheim, L. Lombardi, Z. Cesanek, S. Houdkova, J. Schubert, D. Jech, L. Celko and Z. Pala, Abradable Coatings for Small Turboprop Engines: A Case Study of Nickel-Graphite Coating, J. Therm. Spray Technol., 2019, 28, p 794–802. https://doi.org/10.1007/s11666-019-00838-4

J. Liu, Y. Yu, T. Liu, X. Cheng, J. Shen and C. Li, The Influence of Composition and Microstructure on the Abradability of Aluminum-Based Abradable Coatings, J. Therm. Spray Technol., 2017, 26, p 1095–1103. https://doi.org/10.1007/s11666-017-0526-9

S. Goergen, Cracking Behaviour, Failure Modes and Lifetime Analysis of M320 Abradable Compressor Seal Coating, Cranfield University, 2012.

E. Irissou, A. Dadouche and R.S. Lima, Tribological Characterization of Plasma-Sprayed CoNiCrAlY-BN Abradable Coatings, J. Therm. Spray Technol., 2013, 23, p 252–261. https://doi.org/10.1007/s11666-013-9998-4

Y.D. Liu, J.P. Zhang, Z.L. Pei, J.H. Liu, W.H. Li, J. Gong and C. Sun, Investigation on High-Speed Rubbing Behavior Between Abrasive Coatings and Al/hBN Abradable Seal Coatings, Wear, 2020, 456–457, p 203389. https://doi.org/10.1016/j.wear.2020.203389

G.P. Wagner, D.B. Allen, B.B. Seth, Abradable Coating Applied with Cold Spray Technique, Google Patents, 2002.

K.J.-P. Bridges, Degradation Mechanisms in Ceramic Abradable Coatings for Hot Section Turbine Components, University of California, Irvine, 2018.

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkimov and V. Fomin, Chapter 5 - Current status of the cold spray process, Cold Spray Technology. Elsevier, Oxford, 2007, p 248–323

R. McCune, A. Papyrin, J. Hall, W. Riggs and P. Zajchowski, An Exploration of the Cold Gas-Dynamic Spray Method for Several Materials Systems, ASM International, Materials Park, OH United States, 1995.

R. Nikbakht, S.H. Seyedein, S. Kheirandish, H. Assadi and B. Jodoin, Asymmetrical Bonding in Cold Spraying of Dissimilar Materials, Appl. Surf. Sci., 2018, 444, p 621–632. https://doi.org/10.1016/j.apsusc.2018.03.103

R. Nikbakht, S.H. Seyedein, S. Kheirandish, H. Assadi and B. Jodoin, The Role of Deposition Sequence in Cold Spraying of Dissimilar Materials, Surf. Coat. Technol., 2019, 367, p 75–85. https://doi.org/10.1016/j.surfcoat.2019.03.065

R. Nikhbakht, M. Saadati, M. Jahazi, H. Assadi, and B. Jodoin, EBSD Analysis Enhancement of Cold Sprayed Composite Materials: Sample Preparation, Annealing, and Scan Optimization, Microscopical Society Symposium of Canada, Université de Sherbrooke, Québec, Canada, (2020).

R. Nikbakht, H. Assadi and B. Jodoin, Intermetallic Phase Evolution of Cold-Sprayed Ni-Ti Composite Coatings: Influence of As-Sprayed Chemical Composition, J. Therm. Spray Technol., 2021, 30, p 119–130. https://doi.org/10.1007/s11666-020-01112-8

R. Nikbakht, M. Saadati, H. Assadi, K. Jahani and B. Jodoin, Dynamic Microstructure Evolution in Cold Sprayed NiTi Composite Coatings, Surf. Coat. Technol., 2021, 421, p 127456. https://doi.org/10.1016/j.surfcoat.2021.127456

R. Nikbakht, H. Assadi, K. Jahani, M. Saadati and B. Jodoin, Cold Spray Deformation and Deposition of Blended Feedstock Powders Not Necessarily Obey the Rule of Mixture, Surf. Coat. Technol., 2021 https://doi.org/10.1016/j.surfcoat.2021.127644

X.L. Xie, Y.C. Xie, Z.Q. Tan, C.Y. Chen, J. Wang, Z.Q. Li, X.P. Li, G. Ji and H.L. Liao, Additive Manufacturing of a CNT/Al6Si Composite with the Nanolaminated Architecture via Cold Spray Deposition, Mater. Sci. Forum, 2018, 941, p 2173–2177. https://doi.org/10.4028/www.scientific.net/MSF.941.2173

E.J.T. Pialago and C.W. Park, Cold Spray Deposition Characteristics of Mechanically alloyed Cu-CNT Composite Powders, Appl. Surf. Sci., 2014, 308, p 63–74. https://doi.org/10.1016/j.apsusc.2014.04.096

J. Choi, N. Okimura, T. Yamada, Y. Hirata, N. Ohtake and H. Akasaka, Deposition of Graphene–Copper Composite Film by Cold Spray from Particles with Graphene Grown on Copper Particles, Diam. Relat. Mater., 2021, 116, p 108384. https://doi.org/10.1016/j.diamond.2021.108384

C. Huang, W. Li, Y. Xie, M.-P. Planche, H. Liao and G. Montavon, Effect of Substrate Type on Deposition Behavior and Wear Performance of Ni-Coated Graphite/Al Composite Coatings Deposited by Cold Spraying, J. Mater. Sci. Technol., 2017, 33, p 338–346. https://doi.org/10.1016/j.jmst.2016.11.016

L. Zhu, S. Hu, B. Xu and G. Zhang, Fabrication and Characterization of Ni-Coated Graphite/Al–Zn Coatings by Cold Spraying, Surf. Eng., 2019, 36, p 1032–1039. https://doi.org/10.1080/02670844.2019.1666227

Y. Zhang, J. Michael Shockley, P. Vo and R.R. Chromik, Tribological Behavior of a Cold-Sprayed Cu–MoS2 Composite Coating During Dry Sliding Wear, Tribol. Lett., 2016, 62, p 9. https://doi.org/10.1007/s11249-016-0646-2

M. Neshastehriz, I. Smid, A.E. Segall and T.J. Eden, On the Bonding Mechanism in Cold Spray of Deformable hex-BN-Ni Clusters, J. Therm. Spray Technol., 2016, 25, p 982–991. https://doi.org/10.1007/s11666-016-0416-6

L.M. Stark, I. Smid, A.E. Segall, T.J. Eden and J. Potter, Self-Lubricating Cold-Sprayed Coatings Utilizing Microscale Nickel-Encapsulated Hexagonal Boron Nitride, Tribol. Trans., 2012, 55, p 624–630. https://doi.org/10.1080/10402004.2012.686088

B. Jodoin, P. Richer, G. Bérubé, L. Ajdelsztajn, A. Erdi-Betchi and M. Yandouzi, Pulsed-Gas Dynamic Spraying: Process Analysis, Development and Selected Coating Examples, Surf. Coat. Technol., 2007, 201, p 7544–7551. https://doi.org/10.1016/j.surfcoat.2007.02.033

M. Yandouzi, L. Ajdelsztajn and B. Jodoin, WC-Based Composite Coatings Prepared by the Pulsed Gas Dynamic Spraying Process: Effect of the Feedstock Powders, Surf. Coat. Technol., 2008, 202, p 3866–3877. https://doi.org/10.1016/j.surfcoat.2008.01.036

M. Yandouzi and B. Jodoin, Cermet Coatings Prepared by Pulsed Gas Dynamic Spraying Process: Effect of the Process Parameters, Surf. Coat. Technol., 2008, 203, p 104–114. https://doi.org/10.1016/j.surfcoat.2008.08.018

M. Yandouzi, P. Richer and B. Jodoin, SiC Particulate Reinforced Al–12Si Alloy Composite Coatings Produced by the Pulsed Gas Dynamic Spray Process: Microstructure and Properties, Surf. Coat. Technol., 2009, 203, p 3260–3270. https://doi.org/10.1016/j.surfcoat.2009.04.001

M. Yandouzi, A.J. Böttger, R.W.A. Hendrikx, M. Brochu, P. Richer, A. Charest and B. Jodoin, Microstructure and Mechanical Properties of B4C Reinforced Al-Based Matrix composite Coatings Deposited by CGDS and PGDS Processes, Surf. Coat. Technol., 2010, 205, p 2234–2246. https://doi.org/10.1016/j.surfcoat.2010.08.143

B. Jodoin, Method for Depositing Particulate Material onto a Surface, Google Patents, 2012.

M. Karimi, G.W. Rankin and B. Jodoin, Shock-Wave Induced Spraying: Gas and Particle Flow and Coating Analysis, Surf. Coat. Technol., 2012, 207, p 435–442. https://doi.org/10.1016/j.surfcoat.2012.07.044

M. Yandouzi, H. Bu, M. Brochu and B. Jodoin, Nanostructured Al-Based Metal Matrix Composite Coating Production by Pulsed Gas Dynamic Spraying Process, J. Therm. Spray Technol., 2012, 21, p 609–619. https://doi.org/10.1007/s11666-011-9727-9

S.T. Oyinbo and T.-C. Jen, A Comparative Review on Cold Gas Dynamic Spraying Processes and technologies, Manuf. Rev., 2019, 6, p 25. https://doi.org/10.1051/mfreview/2019023

E. Irissou, L.-P. Lefebvre, Porous Metal Coatings Using Shockwave Induced Spraying, Google Patents, 2017.

M. Karimi Esfahani, Advancement of Shock-wave Induced Spraying Process through the Study of Gas and Particle Flow Fields, Ph.D. Thesis, University of Windsor, 2013.

H. Assadi, T. Schmidt, H. Richter, J.-O. Kliemann, K. Binder, F. Gärtner, T. Klassen and H. Kreye, On Parameter Selection in Cold Spraying, J. Therm. Spray Technol., 2011, 20, p 1161–1176. https://doi.org/10.1007/s11666-011-9662-9

N. Fan, J. Cizek, C. Huang, X. Xie, Z. Chlup, R. Jenkins, R. Lupoi and S. Yin, A New Strategy for Strengthening Additively Manufactured Cold Spray Deposits Through in-Process Densification, Addit. Manuf., 2020, 36, p 101626. https://doi.org/10.1016/j.addma.2020.101626

Y. Wang, Y. Zhu and R. Li, Microstructure and Wear Behavior of Cold-Sprayed Cu-BNNSs Composite Coating, J. Therm. Spray Tech., 2021, 30, p 1482–1492. https://doi.org/10.1007/s11666-021-01227-6

S. Yin, J. Cizek, J. Cupera, M. Hassani, X. Luo, R. Jenkins, Y. Xie, W. Li and R. Lupoi, Formation Conditions of Vortex-Like Intermixing Interfaces in Cold Spray, Mater. Des., 2021, 200, p 109444. https://doi.org/10.1016/j.matdes.2020.109444

W.D. Sun, J. Wang, K.W. Wang, J.J. Pan, R. Wang, M. Wen and K. Zhang, Turbulence-like Cu/MoS2 Films: Stucture, Mechanical and Tribological Properties, Surf. Coat. Technol., 2021, 422, p 127490. https://doi.org/10.1016/j.surfcoat.2021.127490

R. Nikbakht, M. Saadati, T.S. Kim, M. Jahazi, H.S. Kim and B. Jodoin, Cold Spray Deposition Characteristic and Bonding of CrMnCoFeNi High Entropy Alloy, Surf. Coat. Technol., 2021, 425, p 127748. https://doi.org/10.1016/j.surfcoat.2021.127748

Acknowledgment

The authors would like to acknowledge the help of Dr. F. Variola from Mechanical Engineering Department of University of Ottawa for providing guidance and access to Raman Spectroscopy facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nikbakht, R., Jodoin, B. Thick Cu-hBN Coatings Using Pulsed Gas Dynamic Spray Process: Coating Formation Analysis and Characterization. J Therm Spray Tech 31, 609–622 (2022). https://doi.org/10.1007/s11666-022-01318-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01318-y