Abstract

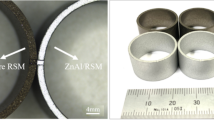

A protective aluminum coating was deposited by cold spray on the surface of a sintered neodymium substrate (Nd2Fe14B) made from an alloy of neodymium, iron, and boron and used as a permanent magnet. Most of the sprayed aluminum particles softened and deposited onto the substrate, forming a uniform and dense coating with a thickness of about 45 μm. The bonding strength and Vickers hardness of the coating were 26.0 MPa and 7.02 GPa, respectively. The corrosion current (Icorr) densities of the sintered NdFeB with and without the aluminum coating in 3.5 wt.% NaCl solution were 3.847 × 10−5 A/cm2 and 3.866 × 10−4 A/cm2, respectively. The sintered NdFeB with the protective aluminum coating survived up to 200 h in the neutral salt spray test (NSS). Its coercivity, remanence, and maximum energy product were 14.813 kOe, 13.994 kGs, and 46.798 MGOe, respectively. They were lower than that of the substrate without coating by 2.94%, 0.03%, and 1.69%.This study showed that the aluminum coating prepared by cold spray could effectively increase the corrosion resistance of the sintered NdFeB magnet with a weak effect on its magnetic properties.

Similar content being viewed by others

References

H. Chen, X. Yang, L. Sun, P. Yu, X. Zhang, and L. Luo, Effects of Ag on the Magnetic and Mechanical Properties of Sintered NdFeB Permanent Magnets, J. Magn. Magn. Mater., 2019, 485, p 49-53.

M. Sagawa, S. Fujimura, N. Togawa, H. Yamamoto, and Y. Matsuura, New Material for Permanent Magnets on a Base of Nd and Fe, J. Appl. Phys., 1984, 55, p 2083-2087.

L.Z. Song, Y.A. Wang, W.Z. Lin, and Q. Liu, Primary Investigation of Corrosion Resistance of Ni-P/TiO2 Composite Film on Sintered NdFeB Permanent Magnet, Surf. Coat. Technol., 2008, 202(21), p 5146-5150.

Y.W. Song, H. Zhang, H.X. Yang, and Z.L. Song, A Comparative Study on the Corrosion Behavior of NdFeB Magnets in Different Electrolyte Solutions, Mater. Corros., 2008, 59(10), p 794-801.

D.F. Cygan and M.J. McNallan, Corrosion of NdFeB Permanent Magnets in Humid Environments at Temperatures up to 150 °C, J. Magn. Magn. Mater., 1995, 1(1-2), p 131-138.

G.W. Warren, G. Gao, and Q. Li, Corrosion of NdFeB Permanent Magnet Materials, J. Appl. Phys., 1991, 70(10), p 6609-6611.

Q.J. He and W. Li, 钕铁硼永磁材料防腐蚀研究进展(Progress in Research on Anticorrosion of NdFeB Permanent Magnet), Met. Funct. Mater., 2001, 8(5), p 8-13. ((in Chinese)).

Q.L. Yuan, J.J. Cao, and Z.J. Su, 烧结型NdFeB永磁体的防腐蚀研究进展(Progress in Research on Anticorrosion of Sintered Type Neodymium Iron Boron), Surf. Technol., 2008, 38(1), p 76-78. ((in Chinese)).

W.Q. Liu, M. Yue, J.X. Zhang, and G.P. Wang, 烧结NdFeB永磁合金本征腐蚀特性研究进展(Intrinsic Corrosion Characteristic of Sintered NdFeB Permanent Magnets), Powder Metall. Technol., 2006, 24(3), p 195-198. ((in Chinese)).

Z. Chen, J.Z. Alicen, X.F. Yi, and F. Chen, Multi-Layered Electroless Ni-P Coatings on Power-Sintered NdFeB Permanent Magnet, J. Magn. Magn. Mater., 2006, 302(1), p 216-222.

E. Chen, K. Peng, W.L. Yang, J.J. Zhu, D.Y. Li, and L.P. Zhou, Effects of Al Coating on Corrosion Resistance of Sintered NdFeB Magnet, Trans. Nonferr. Met. Soc. China, 2014, 24(9), p 2864-2869.

W.C. Lang, B. Gao, W. Chen, and B.Z. Wu, 高性能工具镀层及其制备技术概括与进展 Overview and Progress of High Performance Tool Coating and Its Preparation Technology, J. Wenzhou Voca. Technol. Colg., 2015, 15(1), p 50-54, 58 (in Chinese).

T.T. Xie, S.D. Mao, C. Yu, S.J. Wang, and Z.L. Song, Structure, Corrosion and Hardness Properties of Ti/Al Multilayers Coated on NdFeB by Magnetron Sputtering, Vacuum, 2012, 86(10), p 1583-1588.

J.L. Li, S.D. Mao, K.F. Sun, X.M. Li, and Z.L. Song, AlN/Al Dual Protective Coatings on NdFeB by DC Magnetron Sputtering, J. Magn. Magn. Mater., 2009, 321(22), p 3799-3803.

S.D. Mao, H.X. Yang, J.L. Li, F. Huang, and Z.L. Song, Corrosion Properties of Aluminium Coatings Deposited on Sintered NdFeB by Ion-Beam-Assisted Deposition, Appl. Surf. Sci., 2011, 257(13), p 5581-5585.

W.Y. Li, X.P. Guo, C. Verdy, L. Dembinski, H.L. Liao, and C. Coddet, Improvement of Microstructure and Property of Cold-Sprayed Cu-4at.%Cr-2at.%Nb Alloy by Heat Treatment, Scr. Mater., 2006, 55(4), p 327-330.

B. Dikici, H. Yilmazer, I. Ozdemir, and M. Isik, The Effect of Post-Heat Treatment on Microstructure of 316L Cold-Sprayed Coatings and Their Corrosion Performance, J. Therm. Spray Technol., 2016, 25(4), p 704-714.

B. Dikici and M. Topuz, Production of Annealed Cold-Sprayed 316L Stainless Steel Coatings for Biomedical Applications and Their in-vitro Corrosion Response, Prot. Met. Phys. Chem. Surf., 2018, 54(2), p 333-339.

A.P. Alkhimov, V.F. Kosarev, and A.N. Papyrin, Gas-Dynamic Spraying, an Experimental Study of the Spraying Process, J. Appl. Mech. Tech. Phys., 1998, 39(2), p 318-323.

V.K. Champagne, D.J. Helfritch, and P.F. Leyman, Magnesium Repair by Cold Spray, Plat. Surf. Finish., 2008, 95(9), p 19-28.

Y.S. Tao, T.Y. Xiong, C. Sun, H. Jin, H. Du, and T.F. Li, Effect of α-Al2O3 on the Properties of Cold Sprayed Al/α-Al2O3 Composite Coatings on AZ91D Magnesium Alloy, Appl. Surf. Sci, 2009, 256(1), p 261-266.

S. Kuroda, J. Kawakita, and M. Takemoto, An 18-Year Exposure Test of Thermal-Sprayed Zn, Al and Zn-Al Coatings in Marine Environment, Corrosion, 2006, 62(7), p 635-647.

T.C. Chen, C.C. Chou, T.Y. Yung, K.C. Tsai, and J.Y. Huang, Wear Behavior of Thermally Sprayed Zn/15Al, Al and Inconel 625 Coatings on Carbon Steel, Surf. Coat. Technol., 2016, 303(Part A), p 78-85.

Y.X. Liu and J.X. Wen, 绿色缓蚀剂对金属铝的缓蚀性能研究进展(Research Progress of Green Corrosion Inhibitor for Aluminum), Guangzhou Chem. Ind., 2019, 47(12), p 27-28. ((in Chinese)).

Z.L. Song, 钕铁硼永磁材料腐蚀和防护研究进展(Research Progress on Corrosion and Protection of NdFeB Permanent Magnetic Materials), 8, p 118-128 (in Chinese).

S.Z. Song and Z.L. Tang, An Electrochemical Impedance Analysis on Al in 3.5% NaCl Solution, J. Chin. Soc. Corros. Prot, 1996, 16(2), p 127-132.

C.C. Ma, X.F. Liu, and C.G. Zhou, Cold-Sprayed Al Coating for Corrosion Protection of Sintered NdFeB, J. Therm. Spray Technol., 2013, 23(3), p 456-462.

M. Yue, J.X. Zhang, W.Q. Liu, and G.P. Wang, Corrosion Kinetics of Spark Plasma Sintering Nd-Fe-B Magnets in Different Electrolytes, IEEE Tran. Magn., 2005, 41(10), p 3892-3894.

Y.S. Huang, X.T. Zeng, X.F. Hu, and F.M. Liu, Corrosion Resistance Properties of Electroless Nickel Composite Coatings, Electrochim. Acta, 2004, 49(25), p 4313-4319.

E. Barsoulkov and J.R. Macdonald, Impedance Spectroscopy Theory, Experiment, and Application, 2nd ed. Wiley, Hoboken, 2005.

J.B. Bessone, D.R. Salinas, C.E. Mayer, M. Ebert, and W.J. Lorenz, An EIS Study of Aluminium Barrier-Type Oxide Films Formed in Different Media, Electrochim. Acta, 1992, 37(12), p 2283-2290.

J.F. Zhang, W. Zhang, C.W. Yan, K.Q. Du, and F.H. Wang, Corrosion Behaviors of Zn-Al-Mn Alloy Composite Coatings Deposited on Magnesium Alloy AZ31B (Mg-Al-Zn), Electrochim. Acta, 2009, 55(2), p 560-571.

H. Zhang, Y.L. Zhao, and Z.D. Jiang, Effects of Temperature on the Corrosion Behavior of 13Cr Martensitic Stainless Steel During Exposure to CO2 and Cl− Environment, Mater. Lett., 2005, 59(27), p 3370-3374.

J.H. Xu, 盐雾试验及盐雾试验箱应用技术基础(Salt Spray Test and Salt Spray Test Chamber Application Technology Foundation), National Defence Industry Press, 1993, p 27-40 (in Chinese).

Y.L. Lu and M.X. Cao, 中性盐雾试验影响因素探讨(Discussion on the Influence Factor of Neutral Salt Spray Test), Meishan Technol., 2012, 1(1), p 56-58. ((in Chinese)).

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Nos. 52062040, 51865044, 52062041), Science and Technology Projects of Inner Mongolia Autonomous Region (2018-810, 2019-1356). The authors are grateful to Dr. Xueping Zhao, Dr. Xiaohu Hou and Dr. Fei Liu from the analysis and test center of Inner Mongolia University of technology for their testing help.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, Y., Bai, Y., Zhu, H. et al. Corrosion Resistance, Mechanical and Magnetic Properties of Cold-Sprayed Al Coating on Sintered NdFeB Magnet. J Therm Spray Tech 30, 2117–2127 (2021). https://doi.org/10.1007/s11666-021-01266-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01266-z