Abstract

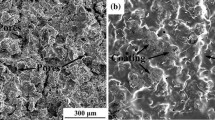

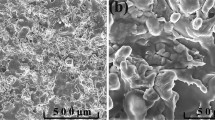

In this article, zinc and aluminum coatings were deposited on plain carbon structural steel (Q235) substrates by electric arc spraying. The coatings were then pore-sealed with a silicone resin to enhance their corrosion performance. The latter was tested in seawater containing sulfate-reducing bacteria by open circuit potential, potentiodynamic polarization and electrochemical impedance spectroscopy. The tests showed that the pore-sealed Al coating had a superior corrosion resistance to the pore-sealed Zn coating in all the corrosion tests. The corrosion rates of the pore-sealed Zn coating first increased as the oxide film was easily destroyed. Then, they decreased as the corrosion products delayed the diffusion of the corrosive medium. On the other hand, the corrosion rates of the pore-sealed Al coating consistently decreased, most likely because of the protective effect of the dense Al2O3 film formed at the early stage of immersion and biological film formed by SRB at the later stage of immersion.

Similar content being viewed by others

References

A.A.M.M. Singh, P.A. Franco and J.S. Binoj, Enhancement of Corrosion Resistance on Plasma Spray Coated Mild Steel Substrate Exposed to Marine Environment, Mater. Today, 2019, 15, p 84–89.

S.A. Galedari, A. Mahdavi, F. Azarmi, Y. Huang and A. McDonald, A Comprehensive revIew of Corrosion Resistance of Thermally-Sprayed and Thermally-Diffused Protective Coatings on Steel Structures, J. Therm. Spray Techn., 2019, 28(4), p 645–677.

O.S.I. Fayomi, A.P.I. Popoola, L.R. Kanyane and T. Monyai, Development of Reinforced In-situ Anti-Corrosion and Wear Zn-TiO2/ZnTiB2 Coatings on Mild Steel, Results Phys., 2017, 7, p 644–650.

H.B. Li, E.Z. Zhou, Y.B. Ren, D.W. Zhang, D.K. Xu, C.G. Yang, H. Feng, Z.H. Jiang, X.G. Li, T.Y. Gu and K. Yang, Investigation of Microbiologically Influenced Corrosion of High Nitrogen Nickel-Free Stainless Steel by Pseudomonas Aeruginosa, Corros. Sci., 2016, 111, p 811–821.

Y.W. Ye, H. Chen, Y.J. Zou, Y. Ye and H.C. Zhao, Corrosion Protective Mechanism of Smart Graphene-Based Self-healing Coating on Carbon Steel, Corros. Sci., 2020, 174, p 108825.

P.A. Rasheed, K.A. Jabbar, H.R. Mackey and K.A. Mahmoud, Recent Advancements of Nanomaterials as Coatings and Biocides for the Inhibition of Sulfate Reducing Bacteria Induced Corrosion, Curr. Opin. Chem. Eng., 2019, 25, p 35–42.

S. Sabooni, M. Ahmadi, E. Galinmoghaddam, R.J. Westerwaal, C. Boelsma, E. Zoestbergen, G.M. Song and Y.T. Pei, Fundamentals of the Adhesion of Physical Vapor Deposited ZnMg-Zn Bilayer Coatings to Steel Substrates, Mater. Des., 2020, 190, p 108560.

S.W. Fu, H.J. Chen, H.T. Wu, K.T. Hung and C.F. Shih, Electrical and Optical Properties of Al: ZnO Films Prepared by Ion-Beam Assisted Sputtering, Ceram. Int., 2016, 42(2), p 2626–2633.

N. Nedfors, S. Mráz, J. Palisaitis, P.O.Å. Persson, H. Lind, S. Kolozsvari, J.M. Schneider and J. Rosen, Influence of the Al Concentration in Ti-Al-B Coatings on Microstructure and Mechanical Properties using Combinatorial Sputtering from a Segmented TiB2/AlB2 Target, Surf. Coat. Tech., 2019, 364, p 89–98.

P.R.C.A. Junior and A.G.M. Pukasiewicz, Evaluation of Microstructure, Mechanical and Tribological Properties of a Babbitt Alloy Deposited by Arc and Flame Spray Processes, Tribol. Int., 2019, 131, p 148–157.

G. Bolelli, M. Bursi, L. Lusvarghi, T. Manfredini, V. Matikainen, R. Rigon, P. Sassatelli and P. Vuoristo, Tribology of FeVCrC Coatings Deposited by HVOF and HVAF Thermal Spray Processes, Wear, 2018, 394, p 113–133.

G. Bolelli, L.M. Berger, T. Börner, H. Koivuluoto, V. Matikainen, L. Lusvarghi, C. Lyphout, N. Markocsan, P. Nylén, P. Sassatelli, R. Trache and P. Vuoristo, Sliding and Abrasive Wear Behaviour of HVOF-and HVAF-Sprayed Cr3C2-NiCr Hardmetal Coatings, Wear, 2016, 358, p 32–50.

W. Deng, Y.L. An, G.L. Hou, S.J. Li, H.D. Zhou and J.M. Chen, Effect of Substrate Preheating Treatment on the Microstructure and Ultrasonic Cavitation Erosion Behavior of Plasma-Sprayed YSZ Coatings, Ultrason. Sonochem., 2018, 46, p 1–9.

K. Hartz-Behrend, J. Schaup, J. Zierhut and J. Schein, Controlling the Twin Wire Arc Spray Process Using Artificial Neural Networks (ANN), J. Therm. Spray Techn., 2016, 25(1–2), p 21–27.

H.S. Lee, J.K. Singh and J.H. Park, Pore Blocking Characteristics of Corrosion Products Formed on Aluminum Coating Produced by Arc Thermal Metal Spray Process in 3.5 wt.% NaCl Solution, Constr. Build. Mater., 2016, 113, p 905–916.

L.M. Liu, Z. Wang and G. Song, Study on Corrosion Resistance Properties of Hydrothermal Sealed Arc Sprayed Aluminium Coating, Surf. Eng., 2010, 26(6), p 399–406.

I.C. Park and S.J. Kim, Corrosion Behavior in Seawater of Arc Thermal Sprayed Inconel 625 Coatings with Sealing Treatment, Surf. Coat. Tech., 2017, 325, p 729–737.

S.J. de Mora, C. Stewart and D. Phillips, Sources and Rate of Degradation of Tri (n-butyl) Tin in Marine Sediments Near Auckland, New Zealand, Mar. Pollut. Bull., 1995, 30(1), p 50–57.

L.D. Chambers, C. Hellio, K.R. Stokes, S.P. Dennington, L.R. Goodes, R.J.K. Wood and F.C. Walsh, Investigation of Chondrus Crispus as a Potential Source of New Antifouling Agents, Int. Biodeter. Biodegr., 2011, 65(7), p 939–946.

S. Liu, X. Zhao, H.C. Zhao, H.Y. Sun and J.M. Chen, Corrosion Performance of Zinc Coated STEEL in Seawater Environment, Chin. J. Oceanol. Limn., 2017, 35(2), p 423–430.

J. Stoulil, B. Domko and J. Šerák, Corrosion Properties of Model Aluminium Alloys for Coating Steel Substrate, Mater. Corros., 2017, 68(1), p 77–81.

S.L. Zheng, C. Li, Q.T. Fu, W. Hu, T.F. Xiang, Q. Wang, M.P. Du, X.C. Liu and Z. Chen, Development of Stable Superhydrophobic Coatings on Aluminum Surface for Corrosion-Resistant, Self-Cleaning, and Anti-Icing Applications, Mater. Design, 2016, 93, p 261–270.

J.D. Brassard, D.K. Sarkar, J. Perron, A. Audibert-Hayet and D. Melot, Nano-Micro Structured Superhydrophobic Zinc Coating on Steel for Prevention of Corrosion and Ice Adhesion, J. Colloid Interf. Sci., 2015, 447, p 240–247.

Y.C. Li, D.K. Xu, C.F. Chen, X.G. Li, R. Jia, D.W. Zhang, W.G. Sand, F.H. Wang and T.Y. Gu, Anaerobic Microbiologically Influenced Corrosion Mechanisms Interpreted using Bioenergetics and Bioelectrochemistry: A Review, J. Mater. Sci. Technol., 2018, 34(10), p 1713–1718.

X.D. Zhao, K.F. Chen, J. Yang, G.F. Xi, H.T. Tian and Q.G. Chen, Effect of Chloride Ion Concentration on Corrosion of Q235 Steel in Sulfate-Reducing Bacteria Containing Solution, Int. J. Electrochem. Sci., 2019, 14, p 875–885.

W. Guo, J. Zhang, Y. Wu, S. Hong and Y. Qin, Fabrication and Characterization of Fe-Based Amorphous Coatings Prepared by High-Velocity Arc Spraying, Mater. Design, 2015, 78, p 118–124.

H.S. Lee and J.K. Singh, Influence of Calcium Nitrate on Morphology and Corrosion Characteristics of Ammonium Phosphate Treated Aluminum Coating Deposited by Arc Thermal Spraying Process, Corros. Sci., 2019, 146, p 254–268.

X. Qiao, Y.M. Wang, W.X. Weng, B.L. Liu and Q. Li, Influence of Pores on Mechanical Properties of Plasma Sprayed Coatings: Case Study of YSZ Thermal Barrier Coatings, Ceram. Int., 2018, 44(17), p 21564–21577.

L. Qiao, Y.P. Wu, S. Hong and J. Cheng, Ultrasonic Cavitation Erosion Mechanism and Mathematical Model of HVOF Sprayed Fe-Based Amorphous/Nanocrystalline Coatings, Ultrason. Sonochem., 2019, 52, p 142–149.

S.U.N. Cheng and H.A.N. Enhou, Effects of Sulfate Reducing Bacteria on Corrosion of Zinc in Marine Sediment, Chin. J. Nonferrous Met., 2003, 13(5), p 1262–1266.

F. Liu, J. Zhang, S. Zhang, W. Li, J. Duan and B. Hou, Effect of Sulphate Reducing Bacteria on Corrosion of Al-Zn-In-Sn Sacrificial Anodes in Marine Sediment, Mater. Corros., 2012, 63(5), p 431–437.

Z.H. Wang, C.T. Chen, J.T. Jiu, S. Nagao, M. Nogi, H. Koga, H. Zhang, G. Zhang and K. Suganuma, Electrochemical Behavior of Zn-xSn High-Temperature Solder Alloys in 0.5 M NaCl Solution, J. Alloy. Compd., 2017, 716, p 231–239.

N. Barati, A. Yerokhin, F. Golestanifard, S. Rastegari and E.I. Meletis, Alumina-Zirconia Coatings Produced by Plasma Electrolytic Oxidation on Al Alloy for Corrosion Resistance Improvement, J. Alloy. Compd., 2017, 724, p 435–442.

Q.J. Zhu and K. Wang, Microstructure and Anti-corrosion Properties of Arc-Sprayed Aluminum Coating in Splash Zone, Adv. Mater. Res. Trans Tech Publications Ltd, 2011, 199, p 1949–1953.

S.J. Kim, S.J. Lee, Y.S. Park, J.Y. Jeong and S.K. Jang, Influence of Sealing on Damage Development in Thermally Sprayed Al–Zn–Zr Coating, Sci. Adv. Mater., 2014, 6(9), p 2066–2070.

H.R. Jeong, H.S. Lee, P. Jalalzai, S.J. Kwon, J.K. Singh, R.R. Hussain, R. Alyousef, H. Alabduljabbar and F. Aslam, Sodium Phosphate Post-treatment on Al Coating: Morphological and Corrosion Study, J. Therm. Spray Tech., 2019, 28(7), p 1511–1531.

J.B. Cheng, X.B. Liang and B.S. Xu, Effects of Crystallization on the Corrosion Resistance of Arc-Sprayed FeBSiNb Coatings, J. Therm. Spray Techn., 2014, 23(3), p 373–379.

E.A. Esfahani, H. Salimijazi, M.A. Golozar, J. Mostaghimi and L. Pershin, Study of Corrosion Behavior of Arc Sprayed Aluminum Coating on Mild Steel, J. Therm. Spray Tech., 2012, 21(6), p 1195–1202.

P. Qi, D. Zhang and Y. Wan, Determination of Sulfate-Reducing Bacteria with Chemical Conversion from ZnO Nanorods Arrays to ZnS Arrays, Sensor. Actuat. B- Chem., 2013, 181, p 274–279.

Q. Jiang, Q. Miao, W.P. Liang, F. Ying, F. Tong, Y. Xu, B.L. Ren, Z.J. Yao and P.Z. Zhang, Corrosion Behavior of Arc Sprayed Al–Zn–Si–RE Coatings on Mild Steel in 3.5 wt% NaCl Solution, Electrochim. Acta, 2014, 115, p 644–656.

L. Benea, A.C. Ciubotariu and W. Sand, Biofilm Formation and Corrosion Resistance of Ni/SiC Nanocomposite Layers, Int. J. Mater. Res., 2013, 104(5), p 489–497.

C. Xie, H. Li, X. Zhou and C. Sun, Corrosion Behavior of Cold Sprayed Pure Zinc Coating on Magnesium, Surf. Coati. Tech., 2019, 374, p 797–806.

B.J. Zheng, Y. Zhao, W.B. Xue and H.F. Liu, Microbial Influenced Corrosion Behavior of Micro-Arc Oxidation Coating on AA2024, Surf. Coat. Tech., 2013, 216, p 100–105.

Acknowledgments

The research was supported by the National Natural Science Foundation of China (Grant Nos. 51579087, 51975183 and 51979083), the Natural Science Foundation of Jiangsu Province, China (Grant No. BK20201316) and the Opening Project of Jiangsu Key Laboratory of Advanced Structural Materials and Application Technology (Grant No. ASMA201902).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qiao, L., Wu, Y., Duan, J. et al. Corrosion Behavior of Arc-Sprayed Pore-Sealed Zn and Al Coatings in Seawater Containing Sulfate-Reducing Bacteria (SRB). J Therm Spray Tech 30, 1557–1565 (2021). https://doi.org/10.1007/s11666-021-01234-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01234-7