Abstract

Conventional and nanostructured NiCoCrAlY coatings were deposited using the high-velocity oxy-fuel thermal spraying technique. The nanostructured NiCoCrAlY powder feedstock for the coatings was produced by the ball-milling method. The microstructures of the as-received and nanostructured powders as well as their developed coatings were investigated by x-ray diffraction, a field-emission scanning electron microscope equipped with energy-dispersive x-ray spectroscopy, and a transmission electron microscope. Williamson–Hall measurements were also carried out to estimate the crystalline size of the powders and coatings. For the evaluation of the oxidation kinetics, the free-standing coating specimens were subjected to short- and long-term isothermal and cyclic oxidation at 1000 and 1100 °C, respectively, under a laboratory air atmosphere. The results indicated that the as-received NiCoCrAlY coating had parabolic oxidation behavior in short- and long-term exposure tests. For the nanostructured NiCoCrAlY coating, in contrast, the long-term oxidation kinetics deviated from parabolic behavior and showed instead sub-parabolic rate behavior. The obtained results also revealed that the nanostructured NiCoCrAlY coating had greater oxidation resistance to both isothermal and cyclic conditions on account of the formation of a dense and slow-growing Al2O3 layer on the coating surface.

Similar content being viewed by others

References

D. Naumenko et al., Overview on recent developments of bondcoats for plasma-sprayed thermal barrier coatings, J. Therm. Spray Technol., 2017, 26(8), p 1743-1757

I. Taie et al., High temperature corrosion resistant coatings for gas flare systems, Ceram. Int., 2018, 44(5), p 5124-5130

S. Bose, High Temperature Coatings, Butterworth-Heinemann, Oxford, 2017

A. Sayyadi-Shahraki et al., Densification and mechanical properties of spark plasma sintered Si3N4/ZrO2 nano-composites, J. Alloys Compd., 2019, 776, p 798-806

S. Ghadami, E. Taheri-Nassaj, and H.R. Baharvandi, Novel HfB2-SiC-MoSi2 composites by reactive spark plasma sintering, J. Alloys Compd., 2019, 809, p 151705

S. Ghadami, H.R. Baharvandi, and F. Ghadami, Influence of the vol% SiC on properties of pressureless Al2O3/SiC nanocomposites, J. Compos. Mater., 2015, 50(10), p 1367-1375

F. Ghadami and A. Sabour Rouh Aghdam, Improvement of high velocity oxy-fuel spray coatings by thermal post-treatments: a critical review, Thin Solid Films, 2019, 678, p 42-52

W. Brandl et al., The oxidation behaviour of HVOF thermal-sprayed MCrAlY coatings, Surf. Coat. Technol., 1997, 94–95, p 21-26

D. Toma, W. Brandl, and U. Köster, The characteristics of alumina scales formed on HVOF-sprayed MCrAlY coatings, Oxid. Met., 2000, 53(1), p 125-137

K. Bobzin et al., Development of oxide dispersion strengthened MCrAlY coatings, J. Therm. Spray Technol., 2008, 17(5), p 853-857

I.M. Allam, D.P. Whittle, and J. Stringer, The oxidation behavior of CoCrAI, systems containing active element additions, Oxid. Met., 1978, 12(1), p 35-66

V.V. Sobolev and J.M. Guilemany, Oxidation of coatings in thermal spraying, Mater. Lett., 1998, 37(4–5), p 231-235

L. Ajdelsztajn et al., Oxidation behavior of HVOF sprayed nanocrystalline NiCrAlY powder, Mater. Sci. Eng. A, 2002, 338(1), p 33-43

F. Tang, L. Ajdelsztajn, and J.M. Schoenung, Characterization of oxide scales formed on HVOF NiCrAlY coatings with various oxygen contents introduced during thermal spraying, Scr. Mater., 2004, 51(1), p 25-29

S. Saeidi, K.T. Voisey, and D.G. McCartney, The effect of heat treatment on the oxidation behavior of HVOF and VPS CoNiCrAlY coatings, J. Therm. Spray Technol., 2009, 18(2), p 209-216

X. Hou et al., Fabrication and characterization of NiCoCrAlY coating deposited on nickel-based superalloy substrates, Vacuum, 2018, 155, p 55-59

W.G. Mao et al., Interfacial fracture characteristic and crack propagation of thermal barrier coatings under tensile conditions at elevated temperatures, Int. J. Fract., 2008, 151(2), p 107-120

H.Y. Qi, X.G. Yang, and R. Li, Interfacial fracture toughness of APS thermal barrier coating under high temperature, Key Eng. Mater., 2007, 348–349, p 181-184

F. Ghadami et al., Effect of vacuum heat treatment on the oxidation kinetics of freestanding nanostructured NiCoCrAlY coatings deposited by high-velocity oxy-fuel spraying, J. Vac. Sci. Technol. A, 2020, 38(2), p 022601

F. Ghadami et al., Synergistic effect of CeO2 and Al2O3 nanoparticle dispersion on the oxidation behavior of MCrAlY coatings deposited by HVOF, Ceram. Int., 2020, 46(4), p 4556-4567

S. Ghadami et al., Effect of SiC and MoSi2 in situ phases on the oxidation behavior of HfB2-based composites, Ceram. Int., 2020, 46, p 20299-20305

D. Mercier, B.D. Gauntt, and M. Brochu, Thermal stability and oxidation behavior of nanostructured NiCoCrAlY coatings, Surf. Coat. Technol., 2011, 205(17), p 4162-4168

G. Pulci et al., High temperature oxidation and microstructural evolution of modified MCrAlY coatings, Metall. Mater. Trans. A, 2014, 45(3), p 1401-1408

B. Saeedi, A. Sabour Rouh Aghdam, and G. Gholami, A study on nanostructured in situ oxide dispersed NiAl coating and its high temperature oxidation behavior, Surf. Coat. Technol., 2015, 276, p 704-713

Q.M. Wang et al., Thermal shock cycling behavior of NiCoCrAlYSiB coatings on Ni-base superalloys: I. Accelerated oxidation attack, Mater. Sci. Eng. A, 2005, 406(1), p 337-349

P. Zhang et al., Long-term oxidation of MCrAlY coatings at 1000 °C and an Al-activity based coating life criterion, Surf. Coat. Technol., 2017, 332, p 12-21

F. Ghadami, A. Sabour Rouh Aghdam, and S. Ghadami, Preparation, characterization and oxidation behavior of CeO2-gradient NiCrAlY coatings applied by HVOF thermal spraying process, Ceram. Int., 2020, 46, p 20500-20509

F. Ghadami, A. Sabour Rouh Aghdam, and S. Ghadami, Mechanism of the oxide scale formation in thermally-sprayed NiCoCrAlY coatings modified by CeO2 nanoparticles, Mater. Today Commun., 2020, 24, p 101357

K. Ma and J.M. Schoenung, Isothermal oxidation behavior of cryomilled NiCrAlY bond coat: homogeneity and growth rate of TGO, Surf. Coat. Technol., 2011, 205(21), p 5178-5185

J. Bergholz et al., Fabrication of oxide dispersion strengthened bond coats with low Al2O3 content, J. Therm. Spray Technol., 2017, 26(5), p 868-879

C. Kaplin and M. Brochu, The effect of grain size on the oxidation of NiCoCrAlY, Appl. Surf. Sci., 2014, 301, p 258-263

F. Ghadami, S. Ghadami, and H. Abdollah-Pour, Structural and oxidation behavior of atmospheric heat treated plasma sprayed WC-Co coatings, Vacuum, 2013, 94, p 64-68

F. Ghadami and A. Sabour Rouh Aghdam, Preparation of NiCrAlY/nano-CeO2 powder with the core-shell structure using high-velocity oxy-fuel spraying process, Mater. Chem. Phys., 2020, 243(1), p 122551

F. Ghadami, A. Sabour Rouh Aghdam, and S. Ghadami, Abrasive wear behavior of nano-ceria modified NiCoCrAlY coatings deposited by the high-velocity oxy-fuel process, Mater. Res. Express, 2020, 6(12), p 1250d6

G.K. Williamson and W.H. Hall, X-ray line broadening from filed aluminium and wolfram, Acta Metall., 1953, 1(1), p 22-31

A.S. Khanna, Introduction to High Temperature Oxidation and Corrosion, ASM International, Cleveland, 2002

J. Lu et al., Significantly improving the oxidation and spallation resistance of a MCrAlY alloy by controlling the distribution of yttrium, Corros. Sci., 2019, 153, p 178-190

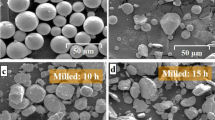

F. Ghadami, A. Sabour Rouh Aghdam, and S. Ghadami, Characterization of MCrAlY/nano-Al2O3 nanocomposite powder produced by high-energy mechanical-milling as feedstock for HVOF spraying deposition, Int. J. Miner. Metall. Mater., 2020, https://doi.org/10.1007/s12613-020-2113-1

M. Tahari, M. Shamanian, and M. Salehi, Microstructural and morphological evaluation of MCrAlY/YSZ composite produced by mechanical alloying method, J. Alloys Compd., 2012, 525, p 44-52

Z. Khodsiani, H. Mansuri, and T. Mirian, The effect of cryomilling on the morphology and particle size distribution of the NiCoCrAlYSi powders with and without nano-sized alumina, Powder Technol., 2013, 245, p 7-12

Z. Horita et al., Development of fine grained structures using severe plastic deformation, Mater. Sci. Technol., 2000, 16(11–12), p 1239-1245

H. Bakker, G.F. Zhou, and H. Yang, Mechanically driven disorder and phase transformations in alloys, Prog. Mater Sci., 1995, 39(3), p 159-241

M. Daroonparvar, M.S. Hussain, and M.A.M. Yajid, The role of formation of continues thermally grown oxide layer on the nanostructured NiCrAlY bond coat during thermal exposure in air, Appl. Surf. Sci., 2012, 261, p 287-297

Q. Zhang et al., Study of oxidation behavior of nanostructured NiCrAlY bond coatings deposited by cold spraying, Surf. Coat. Technol., 2008, 202(14), p 3378-3384

F. Ghadami et al., Structural characteristics and high-temperature oxidation behavior of HVOF sprayed nano-CeO2 reinforced NiCoCrAlY nanocomposite coatings, Surf. Coat. Technol., 2019, 373, p 7-16

K.A. Aly et al., Lattice strain estimation for CoAl2O4 nano particles using Williamson–Hall analysis, J. Alloys Compd., 2016, 676, p 606-612

M.S. Khoshkhoo et al., Grain and crystallite size evaluation of cryomilled pure copper, J. Alloys Compd., 2011, 509, p S343-S347

R.A. Mahesh, R. Jayaganthan, and S. Prakash, A study on the oxidation behavior of HVOF sprayed NiCrAlY-0.4wt.% CeO2 coatings on superalloys at elevated temperature, Mater. Chem. Phys., 2010, 119(3), p 449-457

L. Luo et al., A high performance NiCoCrAlY bond coat manufactured using laser powder deposition, Corros. Sci., 2017, 126, p 356-365

H. Wang et al., Hot corrosion behaviour of low Al NiCoCrAlY cladded coatings reinforced by nano-particles on a Ni-base super alloy, Corros. Sci., 2010, 52(10), p 3561-3567

Y. Wang et al., The effects of ceria on the mechanical properties and thermal shock resistance of thermal sprayed NiAl intermetallic coatings, Intermetallics, 2008, 16(5), p 682-688

C. Nordhorn et al., Effects of thermal cycling parameters on residual stresses in alumina scales of CoNiCrAlY and NiCoCrAlY bond coats, Surf. Coat. Technol., 2014, 258, p 608-614

X. Sun et al., Mechanical properties and thermal shock resistance of HVOF sprayed NiCrAlY coatings without and with nano ceria, J. Therm. Spray Technol., 2012, 21(5), p 818-824

K.A. Unocic et al., High-temperature behavior of oxide dispersion strengthening CoNiCrAlY, Mater. High Temp., 2018, 35(1–3), p 108-119

L. Ajdelsztajn et al., Synthesis and oxidation behavior of nanocrystalline MCrAlY bond coatings, J. Therm. Spray Technol., 2005, 14(1), p 23-30

M.J. Lance et al., APS TBC performance on directionally-solidified superalloy substrates with HVOF NiCoCrAlYHfSi bond coatings, Surf. Coat. Technol., 2015, 284, p 9-13

K.A. Unocic and B.A. Pint, Characterization of the alumina scale formed on a commercial MCrAlYHfSi coating, Surf. Coat. Technol., 2010, 205(5), p 1178-1182

J. Lu et al., Effect of microstructure of a NiCoCrAlY coating fabricated by high-velocity air fuel on the isothermal oxidation, Corros. Sci., 2019, 159, p 108126

J. Lu et al., Superior oxidation and spallation resistant NiCoCrAlY bond coat via homogenizing the yttrium distribution, Corros. Sci., 2019, 159, p 108145

H.E. Evans and M.P. Taylor, Diffusion cells and chemical failure of MCrAlY bond coats in thermal-barrier coating systems, Oxid. Met., 2001, 55(1), p 17-34

B.N. Popov, Corrosion Engineering: Principles and Solved Problems, Elsevier, Amsterdam, 2015

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghadami, F., Sabour Rouh Aghdam, A. & Ghadami, S. Isothermal and Cyclic Oxidation Behavior of HVOF-Sprayed NiCoCrAlY Coatings: Comparative Investigations on the Conventional and Nanostructured Coatings. J Therm Spray Tech 29, 1926–1942 (2020). https://doi.org/10.1007/s11666-020-01111-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01111-9