Abstract

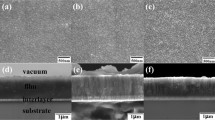

Diamond-like carbon (DLC) films have a high hardness and a low friction coefficient. Therefore, DLC films are applied in industrial fields to reduce energy consumption. However, DLC films can only be obtained as coatings, and DLC films of only micrometer thickness can be deposited on substrates. In this study, we focused on the cold spray (CS) technique as a means of obtaining a DLC-containing metal composite. DLC-containing metal composite films with a millimeter thickness and a low friction coefficient were obtained by depositing DLC-coated metal [copper (Cu) and titanium (Ti)] particles by the CS technique. For Cu particles, DLC-coated particles were prepared with two different deposition times. Then, composite films were fabricated by the CS technique using these particles. The thickness of the DLC-containing Cu(Cu-DLC) composite film was 200 μm and that of the DLC-containing Ti (Ti-DLC30) composite film was 252 μm, and the introduction of DLC into the metal films was demonstrated by Raman spectroscopy. Then, we conducted a sliding test using a ball to evaluate the sliding characteristic of each film. The Cu-DLC composite films deposited from thin DLC-coated Cu particles behaved as a solid lubricant in the ball-on-disk test and Cu-DLC composite films deposited from thick DLC-coated Cu particles acted as an abrasive. For Ti particles, DLC was graphitized and acted as an abrasive.

Similar content being viewed by others

References

A. Grill, Diamond-like Carbon: The State of Art, Diam. Relat. Mater., 1999, 8(3), p 428-434

J. Robertson, Property of Diamond like Carbon, Surf. Coat. Technol., 1992, 50(3), p 185-203

M. Ikeyama, S. Nakao, Y. Miyagawa, and S. Miyagawa, Effects of Si Content in DLC Films on Their Friction and Wear Properties, Surf. Coat. Technol., 2005, 191(1), p 38-42

M. Kano, DLC Coating Technology Applied to Sliding Parts of Automotive Engine, New Diam. Front. Carbon Technol., 2006, 16(4), p 201-210

K. Bewilogua and D. Hofmann, History of Diamond-like Carbon Films—From First Experiments to Worldwide Applications, Surf. Coat. Technol., 2014, 242(15), p 214-225

R. Hauert, An Overview on the Tribological Behavior of Diamond-like Carbon in Technical and Medical Applications, Tribol. Int., 2004, 37(11), p 991-1003

A. Matthews and S. Eskildsen, Engineering Applications for Diamond-like Carbon, Diam. Relat. Mater., 1994, 3(4), p 902-911

K. Hirakuni, M. Yoshimura, and G. Friedbacher, Application of DLC Films as Masks for Integrated Circuit Fabrication, Diam. Relat. Mater., 2003, 12(3), p 1013-1017

Y. Nishimura, R. Ohkawa, H. Oka, H. Akamatsu, K. Azuma, and M. Yatsuzuka, Uniform Coating of Thick DLC Film on Three-Dimensional Substrates, Nucl. Inst. Methods Phys. Res. B, 2003, 206, p 696-699

L. Zhang, F. Wang, L. Qiang, K. Gao, B. Zhang, and J. Zhang, Recent Advances in the Mechanical and Tribological Properties of Fluorine-Containing DLC Films, R. Soc. Chem., 2015, 5, p 9635-9649

J. Vetter, G. Barbezat, J. Crummenauer, and J. Avissar, Surface Treatment Selections for Automotive Applications, Surf. Coat. Technol., 2005, 200(5), p 1962-1968

H. Dai, X. Zhong, J. Li, Y. Zhang, J. Meng, and X. Cao, Thermal Stability of Double-Ceramic-Layer Thermal Barrier Coatings with Various Coating Thickness, Mater. Sci. Eng. A, 2006, 433(1), p 1-7

X. Luo, C. Li, F. Shang, G. Yang, Y. Wang, and C. Li, High Velocity Impact Induced Microstructure Evolution During Deposition of Cold Spray Coatings: A Review, Surf. Coat. Technol., 2014, 254(18), p 11-20

H. Assadi, F. Gartner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

Q. Jun, L. Jianbin, W. Shizhu, W. Jing, and L. Wenzhi, Mechanical and Tribological Properties of Non-hydrogenated DLC Films Synthesized by IBAD, Surf. Coat. Technol., 2000, 128(1), p 324-328

S. Fujimoto, H. Akasaka, T. Suzuki, N. Ohtake, and O. Takai, Structure and Mechanical Properties of Diamond-Like Carbon Films Prepared from C2H2 and H2 Mixtures by Pulse Plasma Chemical Vapor Deposition, Jpn. J. Appl. Phys., 2010, 49, p 075501-7-075501-9

J. Schwan, S. Ulrich, V. Batori, H. Ehrhardt, and P. Silva, Raman Spectroscopy on Amorphous Carbon Films, Jpn. J. Appl. Phys., 1996, 8, p 440-447

P. Tan, C. Hu, J. Dong, W. Shen, and B. Zhang, Polarization Properties, High-order Raman Spectra, and Frequency Asymmetry Between Stokes and anti-Stokes Scattering of Raman Modes in a Graphite Whisker, Phys. Rev. B, 2001, 64, p 214301-1-12

D. Knight and W. White, Characterization of Diamond Films by Raman Spectroscopy, J. Mater. Res., 1989, 4(2), p 385-393

W. Ensinger, Formation of Diamond-like Carbon Films by Plasma-Based Ion Implantation and Their Characterization, New Diam. Front. Carbon Technol., 2006, 16(5), p 1-31

M. Tonosaki, E. Kato, M. Yajima, and Y. Takei, 3D Surface Modification of Micro Trenched Structure, Vacuum, 2004, 74, p 693-698

S. Flege, R. Hatada, T. Vogel, E. Bruder, M. Major, W. Ensinger, and K. Baba, Tightly Adhering Diamond-like Carbon Films on Copper Substrates by Oxygen Pre-implantation, Surf. Coat. Technol., 2018, 335, p 134-139

D. He, R. Manory, and N. Grady, Wear of Railway Contact Wires Against Current Collector Materials, Wear, 1998, 215(2), p 146-155

T. Ding, G. Chen, X. Wang, M. Zhu, W. Zhang, and W. Zhou, Friction and Wear Behavior of Pure Carbon Strip Sliding Against Copper Contact Wire Under AC Passage at High Speeds, Tribol. Int., 2011, 44(4), p 437-444

Acknowledgments

Part of this work was financially supported by Ohata foundation. Part of work was supported by JSPS KAKENHI Grant No. 17KK0111. We would like to acknowledge the support of CS process by Startack Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Okimura, N., Choi, J., Nakayama, W. et al. Metal Matrix Composites Using Diamond-like Carbon-Coated Particles Fabricated by Cold Spray Technique. J Therm Spray Tech 29, 1660–1668 (2020). https://doi.org/10.1007/s11666-020-01071-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01071-0