Abstract

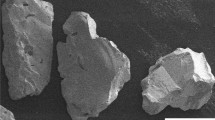

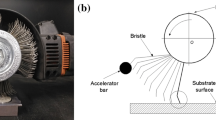

The formation of thermally grown oxide (TGO), which is composed of alumina and mixed oxides, leads to the delamination of thermal barrier coating (TBC). In this study, to improve the oxidation resistance and adhesion strength of TBCs, grinding and grit-blasting treatments with alumina grits were applied to the surface of the bond-coat (BC) before deposition of the top-coat (TC). These treatments are expected to pre-form an alumina layer as an oxidation barrier and also optimize the TC/BC interfacial roughness. A high-temperature exposure test of TBC specimens grit-blasted with alumina grits of different sizes (B-TBC) revealed the growth of a continuous alumina layer in the B-TBC specimens in contrast to the formation of a complex TGO with alumina and mixed oxides in non-blasted TBC (S-TBC). Moreover, the area and thickness of TGO in the B-TBC specimens were much lower than those in the S-TBC. An indentation test was conducted to evaluate the TC/BC interfacial fracture toughness KIFC which confirmed a significantly higher KIFC of the B-TBC specimens than that of the S-TBC specimen. These results demonstrated that the grinding and grit-blasting treatments are effective in improving the oxidation resistance and adhesion strength of the TBC system.

Similar content being viewed by others

References

J.T. DeMasi-Marcin and D.K. Gupta, Protective Coatings in the Gas Turbine Engine, Surf. Coat. Technol., 1994, 68–69, p 1-9

B.C. Wu, E. Chang, S.F. Chang, and D. Tu, Degradation Mechanisms of ZrO2–8 wt% Y2O3/Ni–22Cr–10Al–1Y Thermal Barrier Coatings, J. Am. Ceram. Soc., 1989, 72(2), p 212-218

K. Ogawa, T. Shoji, H. Aoki, N. Fujita, and T. Torigoe, Mechanistic Understanding for Degraded Thermal Barrier Coatings, JSME Int. J. Ser. A Solid Mech. Mater. Eng., 2000, 44(4), p 507-513

W.R. Chen, E. Irissou, X. Wu, J.G. Legoux, and B.R. Marple, The Oxidation Behavior of TBC with Cold Spray CoNiCrAlY Bond Coat, J. Therm. Spray Technol., 2011, 20(1–2), p 132-138

M. Daroonparvar, M. Azizi Mat Yajid, N.M. Yusof, and M. Sakhawat Hussain, Improved Thermally Grown Oxide Scale in Air Plasma Sprayed NiCrAlY/Nano-YSZ Coatings, J. Nanomater., 2013, 2013, p 1-9

Z. Xu, R. Mu, L. He, and X. Cao, Effect of Diffusion Barrier on the High-Temperature Oxidation Behavior of Thermal Barrier Coatings, J. Alloys Compd., 2008, 466, p 471-478

Z. Xu, R. Mu, L. He, and X. Cao, Effect of Diffusion Barrier on the High-Temperature Oxidation Behavior of Thermal Barrier Coatings, J. Alloys Compd., 2008, 37(2), p 57-61

H. Abdeldaim and N. El Mahallawy, The Effect of Sol–Gel Al2O3 Interlayer on Oxidation Behaviour of TBC System, Surf. Coat. Technol., 2018, 350, p 469-479

Y.J. Chen, S.Q. Liu, X.P. Lin, Z.P. Wang, and L.J. Wang, The Effect of Vacuum Heat Treatment on the Oxidation Behavior of APS Thermal Barrier Coating, Adv. Mater. Res., 2011, 239–242, p 3127-3130

A.C. Karaoglanli, K.M. Doleker, B. Demirel, A. Turk, and R. Varol, Effect of Shot Peening on the Oxidation Behavior of Thermal Barrier Coatings, Appl. Surf. Sci., 2015, 354, p 314-322

M.F. Bahbou, P. Nylén, and J. Wigren, Effect of Grit Blasting and Spraying Angle on the Adhesion Strength of a Plasma-Sprayed Coating, J. Therm. Spray Technol., 2003, 13(4), p 508-514

Y. Yamazaki, H. Fukanuma, and N. Ohno, Effect of Interfacial Roughness of Bond Coat on the Residual Adhesion Strength of a Plasma Sprayed TBC System after Thermal Cycle Fatigue, J. Solid Mech. Mater. Eng., 2010, 4(2), p 196-207

R. Eriksson, S. Sjöström, H. Brodin, S. Johansson, L. Östergren, and X.H. Li, Influence of Interface Roughness on the Fatigue Life of Thermal Barrier Coatings,” 13th International Conference on Fracture 2013, Beijing, China, ICF 2013, 2013, p. 1-10.

W. Nowak, D. Naumenko, G. Mor, F. Mor, D.E. Mack, R. Vassen, L. Singheiser, and W.J. Quadakkers, Effect of Processing Parameters on MCrAlY Bondcoat Roughness and Lifetime of APS–TBC Systems, Surf. Coat. Technol., 2014, 260, p 82-89

M. Arai, Interfacial Fracture Toughness Evaluation of Ceramic Thermal Barrier Coatings Based on Indentation Test Method, J. Soc. Mater. Sci., 2009, 58(11), p 917-923

Y. Yamazaki, M. Arai, Y. Miyashita, H. Waki, and M. Suzuki, Determination of Interface Fracture Toughness of Thermal Spray Coatings by Indentation, J. Therm. Spray Technol., 2013, 22(8), p 1358-1365

Y. Liu, T. Nakamura, V. Srinivasan, A. Vaidya, A. Gouldstone, and S. Sampath, Non-linear Elastic Properties of Plasma-Sprayed Zirconia Coatings and Associated Relationships with Processing Conditions, Acta Mater., 2007, 55(14), p 4667-4678

M. Mellali, A. Grimaud, A.C. Leger, P. Fauchais, and J. Lu, Alumina Grit Blasting Parameters for Surface Preparation in the Plasma Spraying Operation, J. Therm. Spray Technol., 1997, 6(2), p 217-227

H.E. Evans and M.P. Taylor, Diffusion Cells and Chemical Failure of MCrAlY Bond Coats in Thermal-Barrier Coating Systems, Oxid. Met., 2001, 55, p 17-34

K.A. Erk, C. Deschaseaux, and R.W. Trice, Grain-Boundary Grooving of Plasma-Sprayed Yttria-Stabilized Zirconia Thermal Barrier Coatings, J. Am. Ceram. Soc., 2006, 89(5), p 1673-1678

A.G. Evans, D.R. Mumm, J.W. Hutchinson, G.H. Meier, and F.S. Pettit, Mechanisms Controlling the Durability of Thermal Barrier Coatings, Prog. Mater Sci., 2001, 46(5), p 505-553

G. Dwivedi, V. Viswanathan, S. Sampath, A. Shyam, and E. Lara-Curzio, Fracture Toughness of Plasma-Sprayed Thermal Barrier Ceramics: Influence of Processing, Microstructure, and Thermal Aging, J. Am. Ceram. Soc., 2014, 97(9), p 2736-2744

S. Suresh, Crack Deflection: Implications for the Growth of Long and Short Fatigue Cracks, Metall. Trans. A, 1983, 14, p 2375-2385

Acknowledgments

We would like to thank Editage (www.editage.jp) for the English language editing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ito, K., Shima, T., Fujioka, M. et al. Improvement of Oxidation Resistance and Adhesion Strength of Thermal Barrier Coating by Grinding and Grit-Blasting Treatments. J Therm Spray Tech 29, 1728–1740 (2020). https://doi.org/10.1007/s11666-020-01057-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01057-y