Abstract

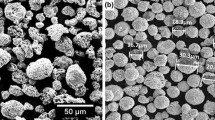

Molten calcium–magnesium–aluminum–silicate (CMAS) mineral particles cause significant degradation of thermal barrier coatings (TBCs) in aero-engines. One approach to protect the TBC coating against the CMAS attack is the application of a sacrificial coating on top of the TBC coating. In this work, Al2O3 coatings were deposited on EB-PVD 7YSZ layers using suspension plasma spraying (SPS) and suspension high velocity oxy-fuel spraying (SHVOF), in order to produce sacrificial topcoats with two different microstructures and porosity levels. The coating systems were tested under CMAS attack with one natural volcanic ash and two artificial CMAS powders by conducting infiltration tests at 1250 °C in the time intervals between 5 min and 10 h. It was found that the porosity and morphology of suspension sprayed alumina topcoats, the chemical composition of the deposits and the infiltration conditions strongly influence the CMAS infiltration, reaction kinetics and formation of the reaction products. While the porous SPS coatings offer limited resistance against CMAS infiltration, the dense SHVOF coatings show promising CMAS sealing behavior. Among the formed reaction products, only (Fe, Mg) Al spinel acted as an efficient barrier against CMAS infiltration. However, the formation of uniform spinel layers strongly depends on the pore morphology of the sacrificial coating and the CMAS chemistry.

Similar content being viewed by others

References

D.R. Clarke, M. Oechsner, and N.P. Padture, Thermal-Barrier Coatings for More Efficient Gas-Turbine Engines, MRS Bull., 2012, 37(10), p 891-902

C.G. Levi, Emerging Materials and Processes for Thermal Barrier Systems, Curr. Opin. Solid State Mater. Sci., 2004, 8(1), p 77-91

A.F. Renteria, B. Saruhan, U. Schulz, H.J. Raetzer-Scheibe, J. Haug, and A. Wiedemann, Effect of Morphology on Thermal Conductivity of EB-PVD PYSZ TBCs, Surf. Coat. Technol., 2006, 201(6), p 2611-2620

S. Sampath, U. Schulz, M.O. Jarligo, and S. Kuroda, Processing Science of Advanced Thermal-Barrier Systems, MRS Bull., 2012, 37(10), p 903-910

R. Naraparaju, U. Schulz, P. Mechnich, P. Döbber, and F. Seidel, Degradation Study of 7 wt.% Yttria Stabilised Zirconia (7YSZ) Thermal Barrier Coatings on Aero-Engine Combustion Chamber Parts Due to Infiltration by Different CaO-MgO-Al2O3-SiO2 Variants, Surf. Coat. Technol., 2014, 260, p 73-81

R. Naraparaju, M. Huttermann, U. Schulz, and P. Mechnich, Tailoring the EB-PVD Columnar Microstructure to Mitigate the Infiltration of CMAS in 7YSZ Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2017, 37(1), p 261-270

R. Naraparaju, P. Mechnich, U. Schulz, and G.C.M. Rodriguez, The Accelerating Effect of CaSO4 Within CMAS (CaO-MgO-Al2O3-SiO2) and Its Effect on the Infiltration Behavior in EB-PVD 7YSZ, J. Am. Ceram. Soc., 2016, 99(4), p 1398-1403

C.G. Levi, J.W. Hutchinson, M.H. Vidal-Setif, and C.A. Johnson, Environmental Degradation of Thermal-Barrier Coatings by Molten Deposits, MRS Bull., 2012, 37(10), p 932-941

R. Naraparaju, J.J.G. Chavez, P. Niemeyer, K.U. Hess, W.J. Song, D.B. Dingwell, S. Lokachari, C.V. Ramana, and U. Schulz, Estimation of CMAS Infiltration Depth in EB-PVD TBCs: A New Constraint Model Supported with Experimental Approach, J. Eur. Ceram. Soc., 2019, 39(9), p 2936-2945

R. Naraparaju, J.J.G. Chavez, U. Schulz, and C.V. Ramana, Interaction and Infiltration Behavior of Eyjafjallajokull, Sakurajima Volcanic Ashes and a Synthetic CMAS Containing FeO with/in EB-PVD ZrO2-65 wt.% Y2O3 Coating at High Temperature, Acta Mater., 2017, 136, p 164-180

M.A. Rivera-Gil, J. Gomez-Chavez, C.V. Ramana, R. Naraparaju, U. Schulz, and J. Munoz-Saldana, High Temperature Interaction of Volcanic Ashes with 7YSZ TBC’s Produced by APS: Infiltration Behavior and Phase Stability, Surf. Coat. Technol., 2019, 378, p 124915

W.J. Song, Y. Lavallee, K.U. Hess, U. Kueppers, C. Cimarelli, and D.B. Dingwell, Volcanic Ash Melting Under Conditions Relevant to Ash Turbine Interactions, Nat. Commun., 2016, 7, p 10795. https://doi.org/10.1038/ncomms10795

P. Mohan, B. Yao, T. Patterson, and Y.H. Sohn, Electrophoretically Deposited Alumina as Protective Overlay for Thermal Barrier Coatings against CMAS Degradation, Surf. Coat. Technol., 2009, 204(6), p 797-801

S. Krämer, J. Yang, and C.G. Levi, Infiltration-Inhibiting Reaction of Gadolinium Zirconate Thermal Barrier Coatings with CMAS Melts, J. Am. Ceram. Soc., 2008, 91(2), p 576-583

U. Schulz and W. Braue, Degradation of La2Zr2O7 and Other Novel EB-PVD Thermal Barrier Coatings by CMAS (CaO-MgO-Al2O3-SiO2) and Volcanic Ash Deposits, Surf. Coat. Technol., 2013, 235, p 165-173

A.K. Rai, R.S. Bhattacharya, D.E. Wolfe, and T.J. Eden, CMAS-Resistant Thermal Barrier Coatings (TBC), Int. J. Appl. Ceram. Technol., 2010, 7(5), p 662-674

X.-F. Zhang, K.-S. Zhou, W. Xu, B.-Y. Chen, J.-B. Song, and M. Liu, In Situ Synthesis of α-Alumina Layer on Thermal Barrier Coating for Protection Against CMAS (CaO-MgO-Al2O3-SiO2) Corrosion, Surf. Coat. Technol., 2015, 261, p 54-59

R. Naraparaju, R.P. Pubbysetty, P. Mechnich, and U. Schulz, EB-PVD Alumina (Al2O3) as a Top Coat on 7YSZ TBCs against CMAS/VA Infiltration: deposition and Reaction Mechanisms, J. Eur. Ceram. Soc., 2018, 38(9), p 3333-3346

L.-M. Berger, F.-L. Toma, and A. Potthoff, Thermal Spraying with Suspensions: An Economic Spray Process, Therm. Spray Bull., 2013, 6(2), p 98-101

F.-L. Toma, A. Potthoff, L.-M. Berger, and C. Leyens, Demands, Potentials, and Economic Aspects of Thermal Spraying with Suspensions: A Critical Review, J. Therm. Spray. Technol., 2015, 24(7), p 1143-1152

A. Potthoff, R. Kratzsch, M. Barbosa, N. Kulissa, O. Kunze, and F.L. Toma, Development and Application of Binary Suspensions in the Ternary System Cr2O3-TiO2-Al2O3 for S-HVOF Spraying, J. Therm. Spray. Technol., 2018, 27(4), p 710-717

M. Barbosa, F.-L. Toma, D. Beitelschmidt, O. Ligabue, S. Bursich, and L. Tagliaferri, Suspension sprayed YSZ thermal barrier coatings: road to industrial application, ITSC 2018—Proceedings of the International Thermal Spray Conference, F. Azarmi, T. Eden, T. Hussain, Y.-C. Lau, H. Li, K. Shinoda, F.-L. Toma, and J. Veilleux, Ed., ASM International, Orlando, 2018, p 113-119

L. Steinberg, C. Mikulla, R. Naraparaju, F.-L. Toma, H. Großmann, U. Schulz, and C. Leyens, Erosion Resistance of CMAS Infiltrated Sacrificial Suspension Sprayed Alumina Top Layer on EB-PVD 7YSZ Coatings, Wear, 2019, 438-439, p 203064

S. Krämer, J. Yang, C.G. Levi, and C.A. Johnson, Thermochemical Interaction of Thermal Barrier Coatings with Molten CaO-MgO-Al2O3-SiO2 (CMAS) Deposits, J. Am. Ceram. Soc., 2006, 89(10), p 3167-3175

E.M. Levin, C.R. Robbins, and H.F. McMurdie, in Phase Diagrams for Ceramists, Vol. I, The American Ceramic Society, Columbus, OH, 1964, p 210, 219, 246

Acknowledgments

The authors express their gratitude to J. Brien, A. Handwerk and D. Peters from DLR Cologne for producing of the EB-PVD 7YSZ layers, as well as for technical support and advisory. The work was performed in the Framework of the Research Project DFG No. SCHU 1372/5 1, LE1373/34-1 funded by DFG-Deutsche Forschungsgemeinschaft (German Research Foundation). The authors acknowledge the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Production Notes: Credit Line: This article is an invited paper selected from presentations at the 2019 International Thermal Spray Conference, held May 26-29, 2019 in Yokohama, Japan, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Mikulla, C., Naraparaju, R., Schulz, U. et al. Investigation of CMAS Resistance of Sacrificial Suspension Sprayed Alumina Topcoats on EB-PVD 7YSZ Layers. J Therm Spray Tech 29, 90–104 (2020). https://doi.org/10.1007/s11666-019-00951-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00951-4