Abstract

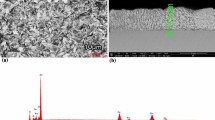

In this research, four coatings including pure zinc, pure aluminum, a double-layered coating of zinc and aluminum, and a coating produced by simultaneous deposition of zinc and aluminum were deposited on a cast iron substrate using electric arc-spraying technique. The coatings were characterized by XRD, SEM and EDS map and spot analyses. Adhesion strength of the coatings was evaluated by three-point bending tests, where double-layered coating indicated the lowest bending angle among the specimens, with detection of cracks at the coating–substrate interface. Coatings produced by simultaneous deposition of zinc and aluminum possessed a relatively uniform distribution of both metals. In order to evaluate the corrosion behavior of the coatings, cyclic polarization and salt spray tests were conducted. Accordingly, pure aluminum coating showed susceptibility to pitting corrosion and other coatings underwent uniform corrosion. For double-layered coating, SEM micrographs revealed zinc corrosion products as flaky particles in the pores formed by pitting on the surface, an indication of penetration of corrosion products from the lower layer (zinc) to the top layer (aluminum). All coatings experienced higher negative corrosion potentials than the iron substrate, indicative of their sacrificial behavior.

Similar content being viewed by others

References

A. Reynaud, Corrosion of cast irons, Shreir’s Corrosion, 1st ed., T. Richardson, Ed., Elsevier Science, Amsterdam, 2010, p 1737-1788

M. Safaeirad, M. Toroghinejad, and F. Ashrafizadeh, Effect of Microstructure and Texture on Formability and Mechanical Properties of Hot-Dip Galvanized Steel Sheets, J. Mater. Process. Technol., 2008, 196, p 205-212

S. Vagge, V. Raja, and R.G. Narayanan, Effect of Deformation on the Electrochemical Behavior of Hot-Dip Galvanized Steel Sheets, Appl. Surf. Sci., 2007, 253, p 8415-8421

H. Li, J. Duan, and D. Wei, Comparison on Corrosion Behaviour of Arc Sprayed and Zinc-Rich Coatings, Surf. Coat. Technol., 2013, 235, p 259-266

X. Lu and L. Li, Electrochemical Corrosion Behavior of Arc Sprayed Zn and Zn15Al Coatings in Simulated Salina Soil and Neutral Meadow Soil Solutions, J. Wuhan Univ. Technol. Mater. Sci. Ed., 2011, 26, p 1152-1156

L. Liu, Z. Wang, and G. Song, Study on Corrosion Resistance Properties of Hydrothermal Sealed Arc Sprayed Aluminium Coating, Surf. Eng., 2010, 26, p 399-406

N.J. Irias and M.L. Miller, Cathodic Protection of Cast Iron Pipe, Am. Soc. Civil Eng., USA, 1998, p 187-194

S. Salavati, L. Pershin, T.W. Coyle, and J. Mostaghimi, Effect of Porosity Content of Arc-Sprayed Alloy 625 Skins on the Flexural Behavior of Nickel Foam Core Sandwich Structures, J. Therm. Spray Technol., 2015, 24, p 215-221

W. Zhao, T. Zhang, R. Xin, M. Wang, H. Ai, J. Sun, and Y. Wang, Effects of Thermally Sprayed Aluminum Coating on the Corrosion Fatigue Behavior of X80 Steel in 3.5 wt% NaCl, J. Therm. Spray Technol., 2015, 24, p 974-983

J.R. Davis, Handbook of Thermal Spray Technology, ASM international, Materials Park, 2004

A. Gulec, O. Cevher, A. Turk, F. Ustel, and F. Yilmaz, Accelerated Corrosion Behaviors of Zn, Al and Zn/15Al Coatings on a Steel Surface, Mater. Technol., 2011, 45, p 477-482

S.B. Saidman and J.B. Bessone, Cathodic Polarization Characteristics and Activation of Aluminium in Chloride Solutions Containing Indium and Zinc Ions, J. App. Electrochem., 1997, 27, p 731-738

J.B. Bessone, The Activation of Aluminium by Mercury Ions in Non-aggressive Media, Corros. Sci., 2006, 48, p 4243-4250

J. Elvins, J.A. Spittle, J.H. Sullivan, and D.A. Worsley, The Effect of Magnesium Additions on the Microstructure and Cut Edge Corrosion Resistance of Zinc Aluminium Alloy Galvanised Steel, Corros. Sci., 2008, 50, p 1650-1658

E. Abedi Esfahani, H. Salimijazi, M.A. Golozar, J. Mostaghimi, and L. Pershin, Study of Corrosion Behavior of Arc Sprayed Aluminum Coating on Mild Steel, J. Therm. Spray Technol., 2012, 21, p 1195-1202

Q. Jiang, Q. Miao, W.P. Liang, F. Ying, F. Tong, Y. Xu, B.L. Ren, Z.J. Yao, and P.Z. Zhang, Corrosion Behavior of Arc Sprayed Al-Zn-Si-RE Coatings on Mild Steel in 3.5 wt% NaCl Solution, Electrochim. Acta, 2014, 115, p 644-656

A. Gulec, O. Cevher, F. Ustel, A. Turk, A. Akinci, and F. Yilmaz, Performance Comparison of Thermal-Sprayed Coatings for Ductile Iron Pipe, Mater. Perform., 2011, 50, p 30-36

D. Rincón, A. Rincón, M. Sanchez, N. Romero, O. Salas, R. Delgado, B. Lopez, J. Uruchurtu, M. Marroco, and Z. Panosian, Evaluating Zn, Al and Al-Zn Coatings on Carbon Steel in a Special Atmosphere, Constr. Build. Mater., 2009, 23, p 1465-1471

R. Xu and G. Song, Post-heat Treatment of Arc-Sprayed Coating Prepared by the Wires Combination of Mg-Cathode and Al-Anode to Form Protective Intermetallic Layers, Appl. Surf. Sci., 2011, 257, p 3097-3102

D.B. Fowler, W. Riggs, and J.C. Russ, Inspecting Thermal Sprayed Coatings, Adv. Mater. Process., 1990, 11, p 41-52

M. Hauer, K.M. Henkel, S. Krebs, and W. Kroemmer, Study of Traverse Speed Effects on Residual Stress State and Cavitation Erosion Behavior of Arc-Sprayed Aluminum Bronze Coatings, J. Therm. Spray Technol., 2017, 26, p 217-228

E. McCafferty, Validation of Corrosion Rates Measured by the Tafel Extrapolation Method, Corros. Sci., 2005, 47, p 3202-3215

E. McCafferty, Introduction to Corrosion Science, 1st ed., Springer, Berlin, 2009, p 148-150

S. Sugimura and J. Liao, Long-Term Corrosion Protection of Arc Spray Zn-Al-Si Coating System in Dilute Chloride Solutions and Sulfate Solutions, Surf. Coat. Technol., 2016, 302, p 398-409

X. Shi, M. Shu, Q. Zhong, J. Zhang, Q. Zhou, and Q.B. Bui, Investigations of Local Corrosion Behavior of Plasma-Sprayed FeCr Nanocomposite Coating by SECM, J. Therm. Spray Technol., 2016, 25, p 595-604

A. Refke, G. Barbezat, and J. Doesburg, Thermal Spraying Material, a Thermally Sprayed Coating, a Thermal Spraying Method an Also a Thermally Coated Workpiece, US20070116886 A1 (2007)

K.W. Hameed and A.S. Yaro, Sacrificial Anode Cathodic Protection of Low Carbon Steel in Seawater, J. Eng., 2007, 13, p 780-1790

J.L. Ma, The Corrosion Behavior of Al-Zn-In-Mg-Ti Alloy in NaCl Solution, Corros. Sci., 2010, 52, p 534-539

N. Perez, Electrochemistry and Corrosion Science, 1st ed., Kluwer Academic Publishers, Dordrecht, 2004

A. Sanati, K. Raeissi, and H. Edris, Investigation of the Corrosion Behavior of Cathodic Arc Evaporated Stainless Steel Coating in 3.5% NaCl, Prot. Met. Phys. Chem. Surf., 2017, 53, p 902-909

R.W. Revie and H.H. Uhlig, Corrosion and Corrosion Control, An Introduction to Corrosion Science and Engineering, 4th ed., Wiley, New York, 2008

A. Poursaee, Determining the Appropriate Scan Rate to Perform Cyclic Polarization Test on the Steel Bars in Concrete, Electrochim. Acta, 2010, 55, p 1200-1206

L.E. Gil, S. Liscano, P. Goudeau, E.L. Bourthis, E.S. Puchi-Cabrera, and M.H. Staia, Effect of TiAlN PVD Coatings on Corrosion Performance of WC-6% Co, Surf. Eng., 2008, 26, p 562-566

E.A. Abde-Wahab, A.H. Marei, O.R. Khalifa, and H.A. Mohamed, Corrosion Behavior of Aluminum Electrode in Absence and in Presence of Sodium Chloride at Different pH Solutions using Toludine as Inhibitor, J. Am. Sci., 2010, 6, p 476-486

T. Hurlen, H. Lian, O.S. Odegard, and T. Valand, Corrosion and Passive Behaviour of Aluminium in Weakly Acid Solution, Electrochim. Acta, 1984, 29, p 579-585

H. Jiménez, J.J. Olaya, J.E. Alfonso, C.B. Mtshali, and C.A. Pineda-Vargas, Corrosion Resistance of Ni-Based WC/Co Coatings Deposited by Spray and Fuse Process Varying the Oxygen Flow, J. Therm. Spray Technol., 2017, 26, p 1708-1719

A. Sanati, K. Raeissi, and H. Edris, Growth Defects and Chromium Content Loss During the Deposition of Stainless Steel by CAE-PVD and Its Effect on the Corrosion and Passivation Behavior of the Coating, Int. J. ISSI, 2015, 12, p 7-16

C. Liu, Q. Bi, A. Leyland, and A. Matthews, An Electrochemical Impedance Spectroscopy Study of the Corrosion Behaviour of PVD Coated Steels in 0.5 N NaCl Aqueous Solution: Part 2: EIS Interpretation of Corrosion Behaviour, Corros. Sci., 2003, 45, p 1257-1273

S. Deshpande, A. Kulkarni, S. Sampath, and H. Herman, Application of Image Analysis for Characterization of Porosity in Thermal Spray Coatings and Correlation with Small Angle Neutron Scattering, Surf. Coat. Technol., 2004, 187, p 6-16

G.E. Totten and D.S. MacKenzie, Handbook of Aluminum, Marcel Dekker Inc, New York, 2003, p 421

Y. Morimoto, K. Nishimura, A. Takahashi, M. Kurosaki, K. Honda, S. Tanaka, and H. Shindo, Excellent Corrosion Resistant Zn-Al-Mg-Si Alloy Hot-Dip Galvanized Steel Sheet “SUPER DYMA”, Nippon Steel Tech. Rep., 2003, 87, p 24-26

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bonabi, S.F., Ashrafizadeh, F., Sanati, A. et al. Structure and Corrosion Behavior of Arc-Sprayed Zn-Al Coatings on Ductile Iron Substrate. J Therm Spray Tech 27, 524–537 (2018). https://doi.org/10.1007/s11666-018-0694-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0694-2