Abstract

In this work, an infrared (IR) thermographic procedure was evaluated as a non-destructive testing tool to detect damage in thermal spray metallic coatings. As model systems, polished HVOF- and HVAF-sprayed Fe-based layers deposited onto steel plates were employed. Damage by external-object impingement was simulated through a cyclic impact-test apparatus, which induced circumferential and radial cracks across all model systems, and interface cracks of different sizes in distinct samples. Damaged and undamaged plates were bulk-heated to above 100 °C using an IR lamp; their free-convection cooling was then recorded by an IR thermocamera. The intentionally induced defects were hardly detectable in IR thermograms, due to IR reflection and artificial “hot” spots induced by residuals of transfer material from the impacting counterbody. As a micrometer-thin layer of black paint was applied, surface emissivity got homogenized and any artifacts were effectively suppressed, so that failed coating areas clearly showed up as “cold spots.” This effect was more apparent when large interface cracks occurred. Finite-element modeling proved the physical significance of the IR-thermography approach, showing that failed coating areas are cooled by surrounding air faster than they are heated by conduction from the hot substrate, which is due to the insulating effect of cracks.

Similar content being viewed by others

References

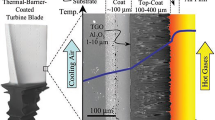

C. Liebert and F.S. Stepka, Ceramic Thermal-Barrier Coatings for Cooled Turbines, J. Aircr., 1977, 14(5), p 487-493

J.T. DeMasi-Marcin and D.K. Gupta, Protective Coatings in the Gas Turbine Engine, Surf. Coat. Technol., 1994, 68, p 1-9

D.R. Clarke and S.R. Phillpot, Thermal Barrier Coating Materials, Mater. Today, 2005, 8(6), p 22-29

R.C. Tucker, Ed., Existing and New Market Opportunities in Thermal Spray Applications, ASM Handbook—Volume 5A: Thermal Spray Technology, (Materials Park, OH, USA), ASM International, 2013, p 243-337

C.-J. Li and A. Ohmori, Relationships between the Microstructure and Properties of Thermally Sprayed Deposits, J. Therm. Spray Technol., 2002, 11(3), p 365-374

Y.-Y. Wang, C.-J. Li, and A. Ohmori, Influence of Substrate Roughness on the Bonding Mechanisms of High Velocity Oxy-Fuel Sprayed Coatings, Thin Solid Films, 2005, 485(1), p 141-147

W.J. Trompetter, A. Markwitz, M. Hyland, and P. Munroe, Evidence of Mechanical Interlocking of NiCr Particles Thermally Sprayed onto Al Substrates, J. Therm. Spray Technol., 2005, 14(4), p 524-529

W. Riggs, D. Rucker, and K. Couch, Testing of Coatings, ASM Handbook—Volume 5A: Thermal Spray Technology, R.C. Tucker, Ed., (Materials Park, OH, USA), ASM International, 2013, p 214-237

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, 2nd ed., Wiley, Chichester, 2008

S. Zhao, H. Wang, N. Wu, and C. Zhang, Nondestructive Testing of the Fatigue Properties of Air Plasma Sprayed Thermal Barrier Coatings by Pulsed Thermography, Rus. J. Nondestruct. Test., 2015, 51(7), p 445-456

M. Seraffon, N.J. Simms, J.R. Nicholls, J. Sumner, and J. Nunn, Performance of Thermal Barrier Coatings in Industrial Gas Turbine Conditions, Mater. High Temp., 2011, 28(4), p 309-314

S.B. Zhao, C.L. Zhang, N.M. Wu, and H.M. Wang, Quality Evaluation for Air Plasma Spray Thermal Barrier Coatings with Pulsed Thermography, Prog. Natl. Sci. Int. Chin. Mater. Res. Soc., 2011, 21(4), p 301-306

V.C. Dina, G.M. Dumitru, and C. Dumitrascu, The Un Destructive Examination by Active Pulse Thermography of the Layers Deposited by Thermal Spraying, Appl. Mech. Mater., 2013, 325-326, p 371-374

Q. Tang, J. Liu, J. Dai, and Z. Yu, Theoretical and Experimental Study on Thermal Barrier Coating (TBC) Uneven Thickness Detection Using Pulsed Infrared Thermography Technology, Appl. Therm. Eng., 2016, 114, p 770-775

M. Schweda, T. Beck, M. Offermann, and L. Singheiser, Thermographic Analysis and Modelling of the Delamination Crack Growth in a Thermal Barrier Coating on Fecralloy Substrate, Surf. Coat. Technol., 2013, 217, p 124-128

T. Ahmed, Z.J. Feng, P.K. Kuo, J. Hartikainen, and J. Jaarinen, Characterization of Plasma Sprayed Coatings Using Thermal Wave Infrared Video Imaging, J. Nondestruct. Eval., 1987, 6(4), p 169-175

J.T. Demasi-Marcin, K.D. Sheffler, and S. Bose, “Mechanisms of Degradation and Failure in a Plasma Deposited Thermal Barrier Coating,” ASME 1989 International Gas Turbine and Aeroengine Congress and Exposition—Volume 5, 1989, p V005T12A004

S. Chaki, P. Marical, S. Panier, G. Bourse, and A. Mouftiez, Interfacial Defects Detection in Plasma-Sprayed Ceramic Coating Components Using Two Stimulated Infrared Thermography Techniques, NDT E Int., 2011, 44(6), p 519-522

H. Reed and W. Hoppe, A Model-Based, Bayesian Characterization of Subsurface Corrosion Parameters in Composite Multi-Layered Structures, AIP Conf. Proc., 2016, 1706(1), p 120010

A.C. Murariu, S. Crâsteţi, and A.V. Bîrdeanu, Active Infrared Thermography Method for Non-Destructive Examination of Coating Layers, Struct. Integr. Life, 2016, 16(1), p 3-8

A.C. Murariu and S. Crasteti, Nondestructive Assessment of Anticorrosive Aluminium Coatings by Active Infrared Thermography, Adv. Mater. Res., 2013, 814, p 235-243

A. Bendada, Nondestructive Inspection of Scuff-Resistant Coating Adhesion Flaws in Automobile Engine Block Cylinders, J. Adhes. Sci. Technol., 2004, 18(8), p 943-950

M. Dvorak, C. Florin, and E. Amrhein, “Online Quality Control of Thermally Sprayed Coatings,” Thermal Spray 2001: New Surfaces for a New Millennium—Proceedings of the International Thermal Spray Conference, C.C. Berndt, K.A. Khor, and E. Lugscheider, Eds., (Materials Park, OH, USA), ASM International, 2011, p 1255-1259

J. Délémontez, M. Taglione, A. Rivière, and E. Martin, “Inspection of HVOF-Coated Pelton Wheels Using Active Thermography”, Quantitative InfraRed Thermograph Conference, 2014.

F. Cernuschi, P. Bison, S. Marinetti, and E. Campagnoli, Thermal Diffusivity Measurement by Thermographic Technique for the Non-destructive Integrity Assessment of TBCs Coupons, Surf. Coat. Technol., 2010, 205(2), p 498-505

J. Nunn, S. Saunders, and J. Banks, Application of Thermography in the Evaluation of Early Signs of Failure of Thermal Barrier Coating Systems, Mater. High Temp., 2005, 22(3/4), p 385-392

A. Milanti, V. Matikainen, G. Bolelli, H. Koivuluoto, L. Lusvarghi, and P. Vuoristo, Microstructure and Sliding Wear Behavior of Fe-Based Coatings Manufactured with HVOF and HVAF Thermal Spray Processes, J. Therm. Spray Technol., 2016, 25(5), p 1040-1055

M. Barletta, G. Bolelli, B. Bonferroni, and L. Lusvarghi, Wear and Corrosion Behavior of HVOF-Sprayed WC-CoCr Coatings on Al Alloys, J. Therm. Spray Technol., 2009, 19(1), p 358-367

P.E. Santangelo, M.A. Corticelli, and P. Tartarini, Spray Cooling by Gently-Deposited Droplets: Experiments and Modeling of Heat-Transfer Mechanisms, 15th International Heat Transfer Conference, (Kyoto, Japan), 2014, p IHTC15-8367

P.E. Santangelo, A.W. Marshall, P. Valdiserri, B. Pulvirenti, and P. Tartarini, Fire Suppression by Water-Mist Sprays: Experimental and Numerical Analysis, 14th International Heat Transfer Conference, Volume 5, (Washington, DC, USA), ASME Heat Transfer Division, 2010, p 571-580

P. Tartarini, M.A. Corticelli, and P.E. Santangelo, Experimental and Numerical Analysis of Droplet Cooling, 14th International Heat Transfer Conference, Volume 6, (Washington, DC, USA), ASME Heat Transfer Division, 2010, p 677-685

P.E. Santangelo, M.A. Corticelli, and P. Tartarini, Experimental and Numerical Analysis of Thermal Interaction between Two Droplets in Spray Cooling of Heated Surfaces, Heat Transf. Eng., 2017. doi:10.1080/01457632.2017.1295737

F.P. Incropera and D.P. DeWitt, Fundamentals of Heat and Mass Transfer, Wiley, New York, 1981

Emissivity Values for Common Materials. http://www.infrared-thermography.com/material.htm. Accessed 3 June 2017

M. Klassen, M. di Marzo, and J. Sirkis, Infrared Thermography of Dropwise Evaporated Cooling, Exp. Therm. Fluid Sci., 1992, 5(1), p 136-141

Ethanol. http://webbook.nist.gov/cgi/cbook.cgi?ID=C64175&Type=IR-SPEC&Index=2. Accessed 3 June 2017

A. Ibrahimbegović, Quadrilateral Finite Elements for Analysis of Thick and Thin Plates, Comput. Methods Appl. Mech. Eng., 1993, 110(3-4), p 195-209

Air Properties. http://www.engineeringtoolbox.com/air-properties-d_156.html. Accessed 30 April 2017

J.A. Garcia, A. Mandelis, B. Farahbakhsh, C. Lebowitz, and I. Harris, Thermophysical Properties of Thermal Sprayed Coatings on Carbon Steel Substrates by Photothermal Radiometry, Int. J. Thermophys., 1999, 20(5), p 1587-1602

L.M. Jiji, Heat Convection, 2nd ed., Springer, Berlin, 2009

M. Corcione, Heat Transfer Correlations for Free Convection from Upward-Facing Horizontal Rectangular Surfaces, WSEAS Trans. Heat Mass Transf., 2007, 2(3), p 48-60

S.V. Patankar, Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Corporation, Washington, DC, USA, 1980

G. Bolelli, A. Milanti, L. Lusvarghi, L. Trombi, H. Koivuluoto, and P. Vuoristo, Wear and Impact Behaviour of High Velocity Air-Fuel Sprayed Fe-Cr-Ni-B-C Alloy Coatings, Tribol. Int., 2016, 95, p 372-390

C. Li, X. Zhang, Y. Chen, J. Carr, S. Jacques, J. Behnsen, M. di Michiel, P. Xiao, and R. Cernik, Understanding the Residual Stress Distribution through the Thickness of Atmosphere Plasma Sprayed (APS) Thermal Barrier Coatings (TBCs) by High Energy Synchrotron XRD; Digital Image Correlation (DIC) and Image Based Modelling, Acta Mater., 2017, 132, p 1-12

Acknowledgments

The authors wish to thank Prof. P. Tartarini (Università degli Studi di Modena e Reggio Emilia, Italy) for providing IR-thermography instrumentation. Mr. G. Urso and CIGS (Centro Interdipartimentale Grandi Strumenti) at Università degli Studi di Modena e Reggio Emilia, Italy, are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Santangelo, P.E., Allesina, G., Bolelli, G. et al. Infrared Thermography as a Non-destructive Testing Solution for Thermal Spray Metal Coatings. J Therm Spray Tech 26, 1982–1993 (2017). https://doi.org/10.1007/s11666-017-0642-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0642-6