Abstract

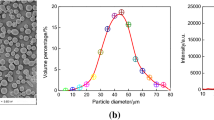

NiMoAl coating was deposited by high velocity oxy-fuel spraying from gas-atomized powders and its tribological properties from 20 to 800 °C under unlubricated conditions were evaluated. Scanning electron microscopy, x-ray diffraction, and Raman spectroscopy were used to characterize the coating and corresponding wear tracks to determine the lubrication mechanisms. The friction coefficient of NiMoAl coating that decreased gradually with the increase of temperature exhibited the highest value of 0.8 at 20 °C and the lowest value of 0.29 at 800 °C. Meanwhile, NiMoAl coating also possessed an excellent anti-wear property and the wear rate of the coating maintained at a relatively low value at all test temperatures. Characterizations of worn surfaces revealed that the coating suffered abrasive wear at the low temperature. When the temperature elevated to 600 and 800 °C, molybdenum oxide and nickel molybdate that were formed through tribo-chemistry reactions acted as lubricants at the high temperature. In addition, NiMoAl coating experienced no obvious oxidation or phase transition on the unrubbed surface during the friction test at 800 °C, indicating that the coating performed both thermal stability and lubrication function at the high temperature.

Similar content being viewed by others

References

H.E. Sliney, Solid Lubricant Materials for High Temperatures—A Review, Tribol. Int., 1982, 15, p 303-315

D.V. Shtansky, A.V. Bondarev, P.V. Kiryukhantsev-Korneev, T.C. Rojas, V. Godinho, and A. Fernández, Structure and Tribological Properties of MoCN-Ag Coatings in the Temperature Range of 25-700 °C, Appl. Surf. Sci., 2013, 273, p 408-414

J.M. Chen, G.L. Hou, J. Chen, Y.L. An, H.D. Zhou, X.Q. Zhao, and J. Yang, Composition Versus Friction and Wear Behavior of Plasma Sprayed WC-(W, Cr)(2)C-Ni/Ag/BaF2-CaF2 Self-lubricating Composite Coatings for Use up to 600 °C, Appl. Surf. Sci., 2012, 261, p 584-592

J.H. Ouyang and S. Sasaki, Tribological Characteristics of Low-pressure Plasma-sprayed Al2O3 Coating from Room Temperature to 800 °C, Tribol. Int., 2005, 38, p 49-57

D. Stone, J. Liu, D.P. Singh, C. Muratore, A.A. Voevodin, and S. Mishra, Layered Atomic Structures of Double Oxides for Low Shear Strength at High Temperatures, Scripta Mater., 2010, 62, p 735-738

C.C. Baker, R.R. Chromik, K.J. Wahl, J.J. Hu, and A.A. Voevodin, Preparation of Chameleon Coatings for Space and Ambient Environments, Thin Solid Films, 2007, 515, p 6737-6743

S. Hong, Y. Wu, G. Li, B. Wang, W. Gao, and G. Ying, Microstructural Characteristics of High-Velocity Oxygen-Fuel (HVOF) Sprayed Nickel-Based Alloy Coating, J. Alloys Compd., 2013, 581, p 398-403

H. Peng, H. Guo, J. He, and S. Gong, Microscale Lamellar NiCoCrAlY Coating with Improved Oxidation Resistance, Surf. Coat. Technol., 2012, 207, p 110-116

C. Dellacorte and J. Laskowski, Tribological Evaluation of PS300: A New Chrome Oxide-based Solid Lubricant Coating Sliding Against Al2O3 from 25 to 650 °C, Tribol. Trans., 1997, 40, p 163-167

M. Kulka, P. Dziarski, N. Makuch, A. Piasecki, and A. Miklaszewski, Microstructure and Properties of Laser-Borided Inconel 600-Alloy, Appl. Surf. Sci., 2013, 284, p 757-771

C. Dellacorte and B. Edmonds, NASA PS400: A New High Temperature Solid Lubricant Coating for High Temperature Wear Applications, NASA Reports, 2009

H.E. Sliney, C. Dellacorte, and V. Lukaszewicz, The Tribology of PS212 Coatings and PM212 Composites for the Lubrication of Titanium 6A1-4V Components of a Stirling Engine Space Power-System, Tribol. Trans., 1995, 38, p 497-506

L. Du, C. Huang, W. Zhang, T. Li, and W. Liu, Preparation and Wear Performance of NiCr/Cr3C2-NiCr/hBN Plasma Sprayed Composite Coating, Surf. Coat. Technol., 2011, 205, p 3722-3728

H. Yang, C. Lee, and S.Y. Hwang, The Effect of Nano-sized Cr2O3 Addition on the Characteristics of NiCr-Cr2O3-Ag-BaF2/CaF2 Coating, Surf. Coat. Technol., 2006, 201, p 38-44

G. Kim, H. Choi, C. Han, S. Uhm, and C. Lee, Characterization of Atmospheric Plasma Spray NiCr-Cr2O3-Ag-CaF2/BaF2 Coatings, Surf. Coat. Technol., 2005, 195, p 107-115

J.R. Davis, Handbook of Thermal Spray Technology, ASM International, 2004

B. Wielage, A. Wank, H. Pokhmurska, T. Grund, C. Rupprecht, and G. Reisel, Development and Trends in HVOF Spraying Technology, Surf. Coat. Technol., 2006, 201, p 2032-2037

L. Du, C. Huang, W. Zhang, J. Zhang, and W. Liu, Effect of NiCr Clad BaF2·CaF2 Addition on Wear Performance of Plasma Sprayed Chromium Carbide-Nichrome Coating, J. Therm. Spray Technol., 2010, 19, p 551-557

ASTM B213-03 Standard Test Method for Flow Rate of Metal Powders. American Society for Testing and Materials. West Conshohocken, PA

ASTM B212-09 Standard Test Method for Apparent Density of Free-Flowing Metal Powders Using the Hall Flowmeter Funnel. American Society for Testing and Materials. West Conshohocken PA

M.K. Stanford, C. DellaCorte, and D. Eylon, Effect of Particle Morphology on Flow Characteristics of a Composite Plasma Spray Powder, J. Therm. Spray Technol., 2004, 13, p 586-592

J. He and E.J. Lavernia, Precipitation Phenomenon in Nanostructured Cr3C2-NiCr Coatings, Mater. Sci. Eng. A, 2001, 301, p 69-79

C. Huang, L. Du, and W. Zhang, Preparation and Characterization of Atmospheric Plasma-sprayed NiCr/Cr3C2-BaF2·CaF2 Composite Coating, Surf. Coat. Technol., 2009, 203, p 3058-3065

P.L. Menezes, S.P. Ingole, M. Nosonovsky, S.V. Kailas, and M.R. Lovell, Tribology for Scientists and Engineers: From Basics to Advanced Concepts, Springer, Berlin, 2013, p 77-79

A. Erdemir, A Crystal-Chemical Approach to Lubrication by Solid Oxides, Tribol. Lett., 2000, 8, p 97-102

S. Usuba and R.B. Heimann, Dense Si3N4 Coatings with High Friction Coefficient Deposited by High-Velocity Pulsed Plasma Spraying, J. Therm. Spray Technol., 2006, 15, p 356-363

W. Gulbiński and T. Suszko, Thin Films of MoO3-Ag2O Binary Oxides-The High Temperature Lubricants, Wear, 2006, 261, p 867-873

M.B. Petersona, S.F. Murraya, and J.J. Florekb, Consideration of Lubricants for Temperatures above 1000 F, Tribol. Trans., 1959, 2, p 225-234

Acknowledgments

The authors are grateful to the National Natural Science Foundation of China (Grant Nos. 51302272, 51275509 and 51175491), the 973 Project of China (No. 2013CB632300), and the Chinese Academy of Sciences for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, J., Zhou, H., Zhao, X. et al. Microstructural Characterization and Tribological Behavior of HVOF Sprayed NiMoAl Coating from 20 to 800 °C. J Therm Spray Tech 24, 348–356 (2015). https://doi.org/10.1007/s11666-014-0142-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0142-x